Project Description

Quality Tests

The Square or Rectangualr H Finned Tube quality is assured by hydrostatic or pneumatic tests, eddy current tests and tensile tests in order to verify the mechanical bonding between inner tubes and outer fins.

Surface Coating

Outside-Red oxide zinc phosphate primer and inside volatile corrosion inhibitor (VCI) in water soluble tablet form.

H-type (square) finned tube specifications: φ32*4 φ32*5 φ38*4 φ38*5 φ42*5 φ48*5 φ51*5 φ51*6, etc., the pipe diameter we can produce: φ25 ~φ65, wall thickness greater than 3mm;

H-type (square) finned tube (finned tube) material: carbon steel, stainless steel, ND steel, alloy steel, etc.

Spiral finned tube specifications: φ16~φ106, wall thickness greater than 2mm;

Spiral finned tube (finned tube) material: carbon steel, stainless steel, ND steel, alloy steel, etc.

It can be customized according to the specific requirements of users, and we can also help users design.

| Name | Base tube (OD) mm |

Fin Pitch (mm) |

length (m) |

|||

| Min | Max | Min | Max | Min | Max | |

| Extruded aluminum fin tube | 12.7 | 51 | 2.1 | 10 | 0.5 | 20 |

| L/LL/KL aluminum fin tube | 19 | 51 | 2.1 | 3.2 | 0.5 | 15 |

| Embedded aluminum fin tube | 19 | 42 | 2.3 | 3.2 | 0.5 | 15 |

| Low fin tube | 12.7 | 32 | 0.8 | 2 | 0.5 | 20 |

| Spiral fin tube | 12.7 | 70 | 0.5 | 20 | ||

| ERW HF spiral fin tube | 16 | 219 | 3 | 25 | 0.5 | 28 |

| ERW HF spiral serrated fin tube | 16 | 219 | 3 | 25 | 0.5 | 28 |

| Serrated width(mm) 10 min~26 max |

Serrated depth(mm) 4 min~16 max |

|||||

| ERW studded tube | 89 | 200 | 16 | 50 | 2 | 15 |

| DC ERW H/HH fin tube | 25 | 51 | 9 | 25 | 1 | 15 |

| H/HH fins | Length(mm) 60 min-150 max |

Thickness(mm) 1.5 min~4 max |

Width(mm) 30 min~50 max |

|||

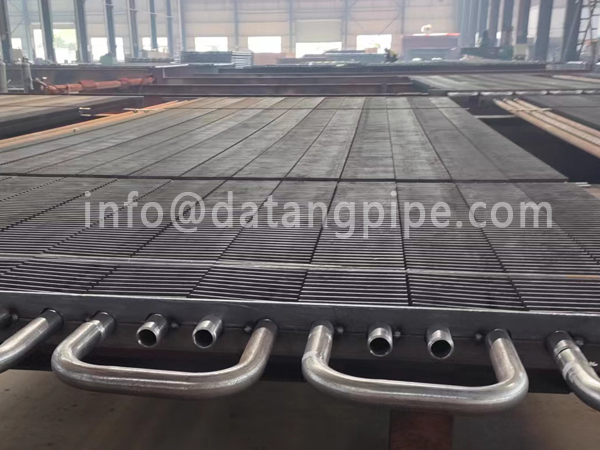

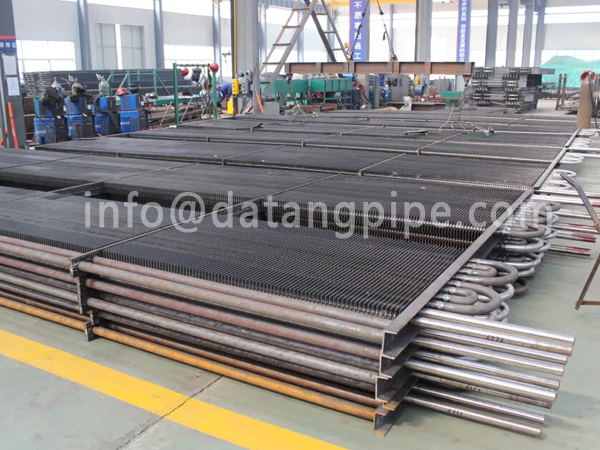

H-finned tubes, also known as square-finned tubes, are designed to recover exhaust heat from power plant boilers, industrial boilers, industrial kilns, ship power plants, etc., and effectively improve fuel utilization. element. Due to the convective heat transfer characteristics of low-temperature flue gas—that is, the heat release coefficient a1 of the flue gas to the pipe wall is much smaller than the heat release coefficient a2 of the pipe wall to the steam-water side, it is very effective to use an extended heating surface on the flue gas side. necessary. The “economizer” (also known as economizer) currently used in boilers includes smooth tube type, spiral warp type, cast iron finned tube type, membrane wall tube type, etc., except for the smooth tube type, the rest belong to Extended heating surface structure.

The disadvantages of welded steel spiral finned tubes in practical application are mainly that the expanded surface area is restricted by the manufacturing process, and the spiral fins wound on the tube are difficult to clean, which is easy to cause ash accumulation and clogging, and its flue gas side The flow resistance is relatively high, so its application range is greatly affected by the quality of the fuel. Its advantages are high productivity, fewer manufacturing processes, and high material utilization.

In the structural design of the square fin tube, a separate structure is adopted for the part of the tube that is prone to ash accumulation, which overcomes the shortcomings of the spiral fin tube, such as easy ash accumulation, ash blocking, and gas resistance, and is an improved product of the spiral fin tube. In addition, the fins of the finned tube form a cantilever beam structure, and under the action of the pulse air flow, the ribs vibrate, which is more conducive to the treatment of dust.

The main component of the economizer in the H-shaped finned tube is the fin, and this type of fin can also be called a butterfly tube or a booster tube. The combined economizer has a high replacement Thermal performance, so the application in different industries is relatively good, and the frequency of use is also very high, but due to its own structural limitations, there are still many industries that cannot use this type of H-shaped finned tube. H-type finned tubes can be divided into two main types in terms of structure, double H-type and H-type. Due to the different forms of structure, they will also be different in the applied industry and environment, but they are all Different arrangements are made according to the order, and everyone should first consider their own needs when choosing.

So what are the specific characteristics of the H-shaped finned tube?

1. The economizer with H-shaped finned tube can directly replace the economizer with bare tube, which not only increases the heat exchange area requirement, but also reduces the number of finned tubes used, and at the same time increases the overall flow of flue gas The cross-section has a corresponding reduction in the flow velocity of the flue gas, mainly reducing the undesirable phenomenon of wear. Because there is a proportional problem between the frequency of wear between the pipes and the velocity of the flue gas, if the velocity of the flue gas decreases significantly, the wear rate will naturally decrease accordingly. After experiments, it is concluded that the H-shaped finned tube itself It has the effect and function of centralized tube ash discharge, so the finned tube has the function of reducing the wear between structures. If the H-shaped finned tube is made into a double H-shaped design, its rigidity will be higher, and it can be directly used as a long pipe to use.

2. Arrange the economizers of H-shaped finned tubes in different orders according to the requirements of use. The H-shaped heat sink can distribute the space in different areas, which has a significant effect on the balance of airflow and the effect of reducing wear and tear. more obvious;

3. Because there are straight channels on both sides of the H-shaped finned tube, the effect of soot blowing is relatively high;

4. The space design of the H-shaped finned tube is relatively tight, so the overall weight is reduced a lot, which also plays a role in reducing the manufacturing cost;

5. The main reason is that the H-shaped finned tube has good energy-saving and consumption-reducing performance. The power generation unit uses the economizer design method, which reduces the waste gas loss by more than half, and the steam utilization rate reaches about 3 kilowatts per ton;

6. H-shaped finned tubes are very convenient and labor-saving in daily maintenance and operation. The economizer adopts an overall assembled manufacturing method with fewer moving parts. The design of the overall structure is relatively simple and easy to install. It is much more convenient, the automation effect of its own design is obvious, the operation and maintenance are more convenient, and the labor force of the laborers is reduced.

Cangzhou Datang Steel Pipe Co., Ltd located in Cangzhou City,the hometown of pipelines, is a collection of research and development, production, sales in one of the enterprises. The company was founded in 2007 with registered capital 10.08 million RMB, and through the IS09001 international quality system certification, we has high frequency resistance welding finned tube production line 18, extruded finned tube equipment 30, laser welding finned tube production line 2, wound finned tube production line 12. The annual capacity can reach 100,000 tons, the specification φ 18-273mm finned tube, according to the customer requirements of the standard production, service has exceeded 3000+ enterprises.

Our companys tenet is to be Chinas most professional pipeline and equipment suppliers, on the basis of seamless steel tube, integrate the national high quality pipe equipment resources, provide one-stop packaging services,quality makes customer trust, service makes customer relieved, result makes customer comfort, building a conscience, good-hearted, have the sense of responsibility, contributes to the society of the enterprise.Our slogan is professional concentrate in pipeline & accessories 20 years.

Inquiry and consulting support.

Sample testing support.

Visit our factory

After-sales service

Training how to install the tubes, and maintenance.

Engineers available to service overseas.

FAQ

Are you a manufacturer?

We are a professional manufacturer focus on the fin tube area.

Does free shipping is possible?

We don’t offer a free shipping service, but we will offer a discount depends on the quantity.

Do you make OEM?

Yes, we do. We manufacture according to your design and brand standards.

How about the delivery time?

According to the sizes and quantity, delivery time is different. We transport by sea and air normally.

Maintenance

We ensure our standards against erosion and provide professional maintenance advice, for quality advice, we can guarantee for one-year after-sales.