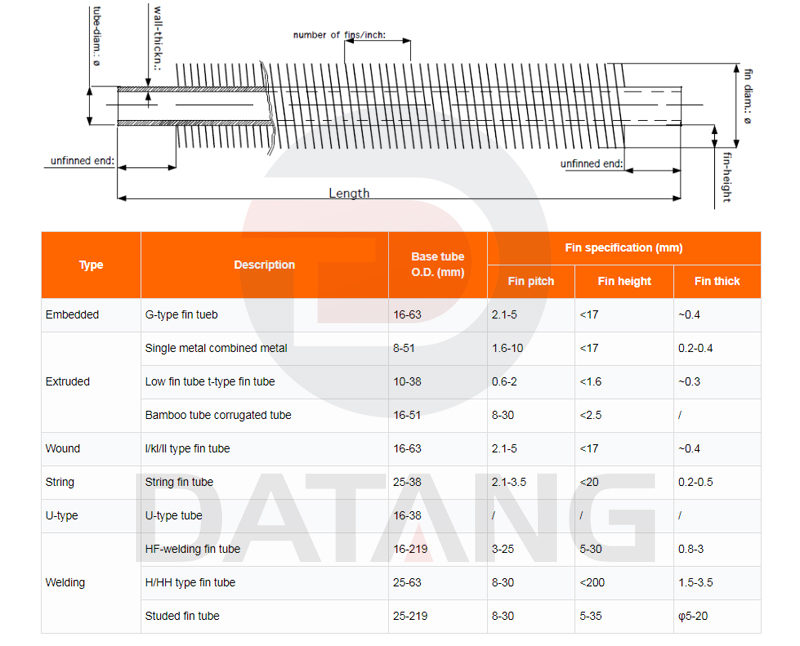

High Frequency Welded Fin Tube for Heat Exchanger

High frequency welded fin tube Quick Details:

Core tube material:

1. Carbon Steel: A106 / A179 /A192 / A210 etc. 2. Stainless Steel: TP304/304L,TP316/TP316L, TP347 etc. 3. Alloy Steel: P5,T5,P9,T9,T11,T22

Fin Material:

1. Aluminum (Alu.1100, Alu.1060) 2. Copper. 3. Steel

Tube/Pipe Size 1.00″ to 15.75″ OD

Fin Height 0.3mm to 49.50mm

Fin Segment Width 5/32″ or 5/16″

Fin Thickness 0.8 mm ~ 4.0 mm

Fin Pitch 1 to 20 fins per inch

High Frequency Welded Fin Tubes by Material

High Frequency Welded Finned Tubes by Application

High frequency welded fin tube(HFW Fin Tube) For Heat Exchangers

High frequency welded fin tube is a spiral winding of steel fins, which is continuously welded on the steel pipe by high frequency resistance welding (HFERW). A high-frequency current is introduced into the workpiece, the welding contact surface is melted or semi-melted by resistance heat, and then appropriate pressure is applied to the welding contact surface to complete the welding of the finned tube. This produces a uniform, clean and continuous finned tube combined with no additional welding material for very efficient heat flow and corrosion resistance.

High-frequency welded spiral finned tube is one of the most widely used spiral finned tubes.

High-frequency welding spiral fin tube is a heat transfer element made by high-frequency welding technology. Its characteristic is that the metal plate is processed and formed through the heating effect of high-frequency current and the continuous rotation of the roller, thus forming a A unique spiral structure.

The main application areas of high-frequency welded spiral fin tubes include various industrial fields. Among them, high-frequency welding technology significantly improves heat transfer efficiency by tightly combining the fins and tubes. This technology utilizes the heating effect of high-frequency current, making it easier for the metal to form the required spiral shape when heated, thus increasing the heat transfer area of the radiator and improving heat transfer efficiency.

The connection method of high-frequency welded spiral fin tubes is usually flange or thread connection. This connection method not only improves production efficiency, but also reduces costs, while ensuring the durability and reliability of the product. In addition, high-frequency welding spiral fin tube has high production efficiency, low cost, durable, reliable welding, high heat conduction output power, is an ideal heat transfer element.

High frequency welded fin tube is also known as high frequency welded spiral finned tube, high frequency welded spiral finned tube is a tubular high-efficiency heat transfer element with spiral fins. The extended surfaces (fins) can be solid or serrated and have up to tens of times more heat transfer area than a bare tube.

The spiral fin tube itself is an efficient heat transfer element with spiral fins. Its heat transfer area is several to dozens of times that of the light tube. It can enhance heat transfer, reduce flow resistance, and reduce metal consumption. quantity, thereby improving the economy and operational reliability of heat exchange equipment.

Manufacturing Process:

HFW Fin Tube is a spiral winding of steel fins, which is continuously welded on the steel pipe by high frequency resistance welding (HFERW). A high-frequency current is introduced into the workpiece, the welding contact surface is melted or semi-melted by resistance heat, and then appropriate pressure is applied to the welding contact surface to complete the welding of the finned tube.

Quality Control for HFW Fin Tube

The quality of the HFW Fin Tube is assured by hydrostatic or pneumatic testing, eddy current testing and tensile testing to verify the mechanical bond between the inner tube and the outer fins

Delivery conditions

Burr-free, dry and blow-out inside, HFW Fin Tube with varnish on both ends.

Features of HFW Fin Tube

1. Due to the fast welding speed and strong self-cooling effect of the weldment, not only the heat affected zone is small, but also oxidation is not easy to occur, so the structure and performance of the weld are very good.

2. Anti-corrosion performance, wear-resistant performance, low contact thermal resistance, high stability, and anti-fouling ability.

3. Large heat exchange area.

Application

HFW Fin Tube (high frequency welded spiral finned tube) is one of the most widely used spiral finned tubes, and is now widely used in power, metallurgy, waste heat recovery in cement industry, petrochemical industry and other industries.

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required

Noted:

1) Supply raw material certificate, quality guarantee, Mill Test Certificate

2 ) Three Inspection : raw material ,pressure,measurement of size , package and finishing

3) Warranty period: within one year after receipt of the goods

4) Packing with Plastic Mat, Waterproof Paper , drying agent/desiccant and plastic cap

For light ,short fin tubes ,we use exporting wooden case

For heavy, long fin tubes ,we use iron frame wooden case

On the top of the package ,we weld more square steel to protect the package

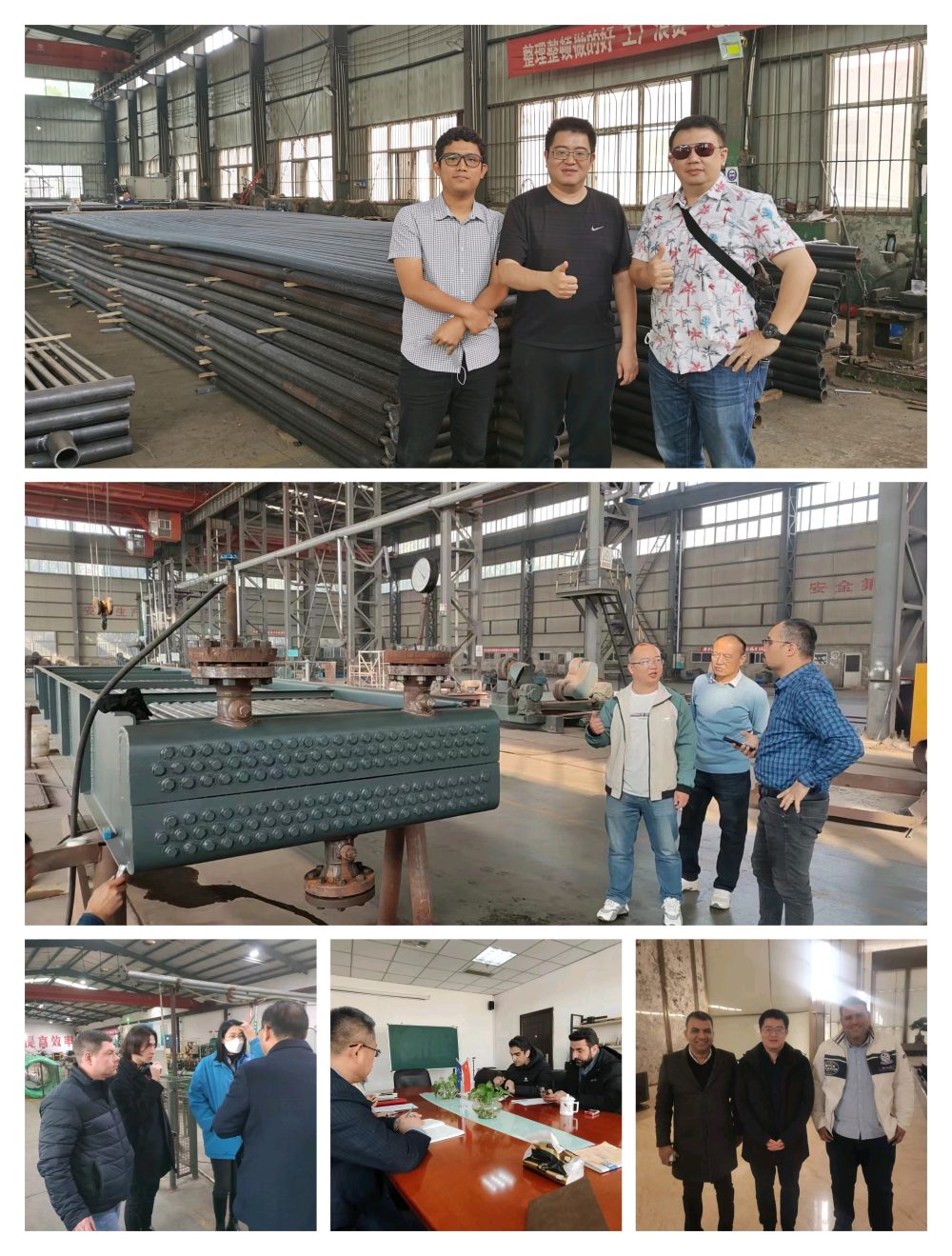

Fin tube Inspection Packing-spiral fin tube,helical finned tube,HFW Fin Tube Datang

Fin tube manufacturing company,High-frequency welding spiral fin tube,finned pipe Datang

Our Certificates-Datang Fin Tube,high spiral fin tube heat exchanger

Customer factory inspection-Datang Fin Tube,Fin Pipe,Finned Tube,steel fin tube

Exhibition Photos,finned pipe,heat exchanger tubes suppliers Datang Fin Tube

|

1

|

Inquiry-Professional quotation, or send inquiry item more details ,we start contact more details

|

|

2

|

Confirm the price, lead time, payment term etc

|

|

3

|

Our sales send the Proforma Invoice with our seal, or you order online to us

|

|

4

|

Customer make the payment for deposit and send us Bank receipt

|

|

5

|

Initial Production Stage-Inform the clients that we have got the payment,And will make the samples according to your request, send

you photos or Samples to get your approval. After approval, we inform that we will arrange the production & inform the estimated time. |

|

6

|

Middle Production-send photos to show the production line which you can see your products . Confirm the estimated delivery time

again. |

|

7

|

End Production-Mass production products photos and samples will send to you for approval. You can also arrange the third party

Inspection |

|

8

|

Clients make payment for balance and Ship goods , Inform the tracking number and check the status for clients

|

|

9

|

Order can be say “finish” when you receive the goods and satisfy with them

|

|

10

|

Feedback to our about Quality , Service, Market Feedback & Suggestion. And we can do better

|

Each base pipe has been tested by eddy current, ultrasonic, and hydraulic pressure, and it is ensured that each weld has no leaks.

Address: Cangzhou City, Hebei Province, China

Contacts: Mrs. Sunny Yang

Whatsapp Number: 0086 15690122018

Email: info@datangpipe.com