Project Description

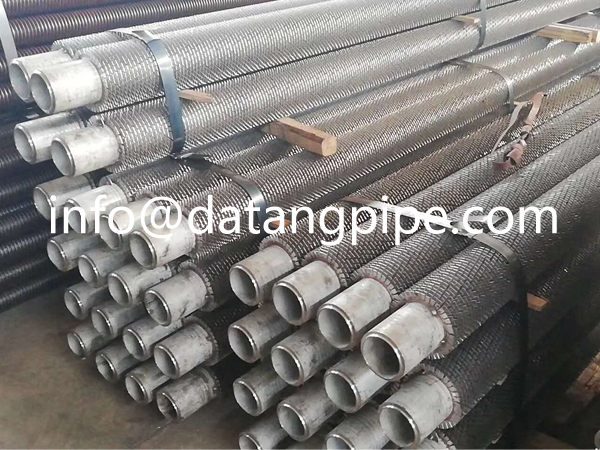

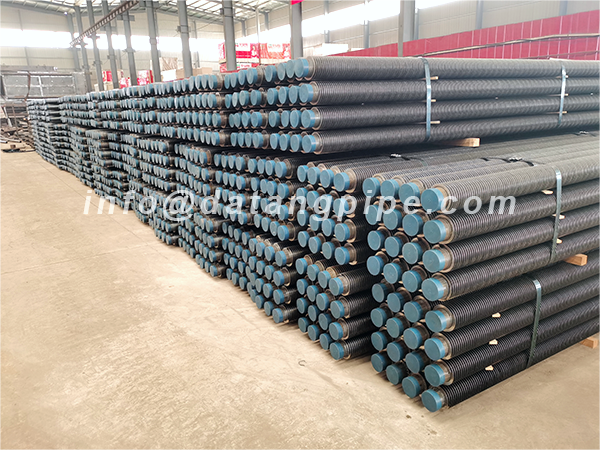

- Product Name: ASTM A179 High Frequency Welded Spiral Carbon Steel Fin Tube for Boiler Economizer

- Leave Your Message

1. Selection and processing of high-quality carbon steel materials for ASTM A179 high-frequency welded spiral carbon steel fin tube

(I) Material selection for ASTM A179 high-frequency welded spiral carbon steel fin tube

High-frequency welded spiral carbon steel fin tubes first have strict requirements on the selection of raw materials, and usually use high-quality carbon steel that meets specific standards. Reasonable control of the carbon content in carbon steel is crucial. The appropriate carbon content can ensure good processing performance while ensuring that the material has a certain strength.

(II) Pretreatment process of ASTM A179 high frequency welded spiral carbon steel fin tube

After selecting the raw materials, pretreatment of carbon steel is a key technical link. This includes cleaning processes such as degreasing and rust removal of carbon steel to remove impurities, oil stains and rust that may exist on the surface, so as to avoid these substances affecting the performance of the fin tube during subsequent processing or use.

The internal structure of carbon steel will also be adjusted through heat treatment processes such as annealing to improve its toughness and processing plasticity, so that carbon steel can be better formed in subsequent manufacturing processes such as rolling and welding, ensuring the overall quality and stable performance of the fin tube.

Datang fin tube manufacturer mainly operates three major sectors: home decoration and industrial heating radiators, fin tubes for heat exchange equipment, waste heat recovery of industrial heat exchange equipment, and annual production of more than 3 million units of various equipment.

2. Advanced fin processing and connection technology of ASTM A179 high-frequency welded spiral carbon steel fin tubes

(I) Fin rolling process of ASTM A179 carbon steel fin tubes

Through professional rolling equipment, thin steel strips or steel plates are rolled according to the predetermined fin shape, size and spacing to make them fit tightly on the surface of the base tube. During the rolling process, it is very important to accurately control the rolling pressure, speed and temperature parameters.

Appropriate pressure can ensure the close connection between the fin and the base tube without causing excessive deformation of the base tube; reasonable rolling speed ensures the continuity and quality stability of the fin forming; and the appropriate temperature can be based on the material properties of carbon steel, so that it is in the best plastic state, thereby rolling out fins with uniform thickness, regular shape and good fit with the base tube, maximizing the heat exchange area and improving the heat exchange efficiency.

(II) Optimization of ASTM A179 carbon steel finned tube connection process

In order to ensure the firmness of the connection between the fin and the base tube and prevent the fin from loosening or falling off due to factors such as thermal expansion and contraction or fluid impact during the heat exchange process, advanced connection processes need to be adopted. Common methods include high-frequency welding and expansion joints.

High-frequency welding can use the heat generated by high-frequency current in a short time to instantly melt and fuse the contact parts of the fin and the base tube together to form a firm connection. This welding method has high weld quality and a small heat-affected zone, and will not cause too much negative impact on the overall performance of the finned tube.

The expansion joint process uses the method of mechanical tube expansion to cause plastic deformation of the base tube, tightly squeeze the fins, and achieve a close fit between the two. It can also achieve a good connection effect and meet the stability requirements of the finned tube in long-term heat exchange operation.

III. Accurate size and tolerance control technology of ASTM A179 high-frequency welded spiral carbon steel finned tubes

In the manufacturing process of high-frequency welded spiral carbon steel finned tubes, strict control of dimensional accuracy and tolerance is an important technical point to ensure its performance.

Whether it is the diameter and wall thickness of the base tube, or the height, spacing and overall length of the finned tube, they all need to be processed and tested according to precise design requirements.

Accurate size control can ensure that when the finned tube is assembled into equipment such as a heat exchanger, the various components are closely matched and seamlessly connected, ensuring that the flow state of the heat medium in the tube and the external fluid between the fins is in line with expectations, avoiding local turbulence and increased flow resistance caused by dimensional deviations, thereby affecting the heat exchange efficiency and the normal operation of the entire system.

Through high-precision processing equipment and strict testing methods, such as the use of tools such as three-coordinate measuring machines to measure and calibrate the key dimensions of the finned tube in real time, each carbon steel finned tube can meet the stringent dimensional tolerance requirements and show stable and efficient heat exchange performance.

3. Effective surface protection technology for high-frequency welded spiral carbon steel finned tubes

Considering the characteristics of carbon steel itself that it is prone to corrosion in some environments, surface protection of carbon steel finned tubes is an indispensable core technology. Common protection methods include galvanizing and painting.

ASTM A179 High-Frequency Welded Spiral Carbon Steel Finned Tubes: Engineering Excellence

I. Material Selection and Preprocessing

-

Carbon Steel Grade Optimization

- Base tubes utilize premium carbon steel (C: 0.15-0.25%) balancing tensile strength (≥300 MPa) and formability.

- Preprocessing includes alkaline degreasing and shot blasting to achieve Sa 2.5 surface cleanliness.

- Annealing at 650-700°C refines grain structure, enhancing ductility for subsequent forming.

-

Manufacturer Capability

- Industrial-scale production (e.g., 300k+ units/year) with integrated R&D for thermal optimization.

| Material Property | Specification | Function |

|---|---|---|

| Carbon Content | 0.15-0.25% | Strength-formability balance |

| Tensile Strength | ≥300 MPa | Pressure resistance |

| Surface Cleanliness | Sa 2.5 | Weld quality assurance |

II. Advanced Manufacturing Processes

-

Fin Rolling Precision

- Spiral fins formed under controlled pressure (50-80 MPa) and temperature (150-200°C) to ensure ≤0.1mm dimensional deviation.

- Optimal fin density: 150-400 fins/meter, increasing heat transfer area 5-8× versus bare tubes.

-

High-Frequency Welding (HFW)

- Parameters: Current 10-50 kHz, weld speed 25-35 m/min, achieving 80-120 MPa bond strength.

- Advantages: Near-parent-metal joint strength with

| Process Parameter | Value Range | Impact |

|---|---|---|

| Welding Speed | 25-35 m/min | Production efficiency |

| Bond Strength | 80-120 MPa | Anti-vibration reliability |

| Fin Height Tolerance | ±0.1 mm | Heat transfer uniformity |

III. Dimensional Control Standards

- Tube OD tolerance: ±0.15mm; fin pitch consistency: ±5%.

- Laser-guided measurement systems ensure concentricity ≤0.2mm/m.

- Critical for flow uniformity: Reduces turbulence resistance by 15-20% versus non-standardized designs.

IV. Surface Protection Systems

- Hot-Dip Galvanizing: 45-85μm zinc coating for >15-year service in humidity ≤80% RH.

- Epoxy-Polyester Coating: Optional 60-120μm layer for chemical resistance (pH 4-10 environments).

| Coating Type | Thickness | Corrosion Resistance | Service Life |

|---|---|---|---|

| Hot-Dip Galvanizing | 45-85μm | Moderate | >15 years |

| Epoxy-Polyester | 60-120μm | High (chemical env.) | 10-12 years |

Performance Advantages

- Thermal Efficiency: Achieves heat transfer coefficients of 90-140 W/m²·K, enabling 30% energy savings versus smooth tubes.

- Structural Integrity: Withstands thermal cycling (ΔT≤150°C) and operational pressures ≤2.5 MPa.

Applications: Industrial boilers, exhaust gas recovery (>85% heat reclaim), and process heating systems.