Project Description

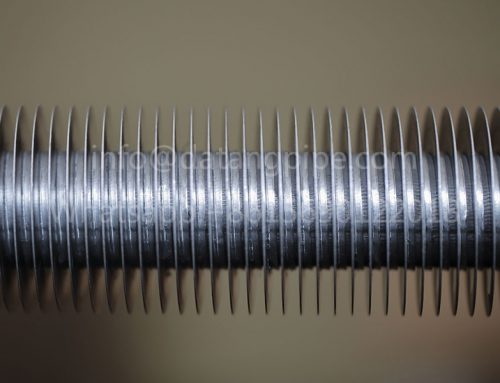

Product Name: KL-Type Wound Fin Tubes | Knurled L Type Finned Tube | KLM Fin Tube

- Leave Your Message

KL-Type Wound Fin Tubes

KL-Type wound fin tubes are a manufacturing technology for steel wound fin tube radiators. As one of the primary heat dissipation components, KL-Type wound fin tubes offer excellent heat dissipation performance, several times or even dozens of times greater than that of ordinary bare tube radiators. These fin tubes offer excellent heat dissipation and are widely used in a variety of applications, covering large areas.

KL-Type wound fin tubes typically have a service life of up to 30 years, and with proper user experience, this service life can be extended to 50 years. The long service life and safety and reliability of fin tube radiators are the main reasons many users choose them.

KL-Type wound fin tube radiators can be manufactured using different processing techniques, radiator types, and specifications based on the user’s desired temperature. Therefore, when selecting a fin tube radiator, users must clearly understand the specific conditions and requirements of their location to select a suitable fin tube radiator with optimal heat dissipation.

Fin tube bundles can be arranged in either a sequential or staggered arrangement. However, because sequential fin tube bundles have a large enclosed vortex area between tubes, they are prone to dust accumulation and require larger dimensions, so a staggered arrangement is generally used. The horizontal and vertical spacing of staggered fin tube bundles significantly affects wear on the heating surfaces, dust accumulation, and flue gas velocity. Considering reducing wear, reducing flue gas velocity, and space constraints, this arrangement is recommended.

After the fin tube economizer renovation, the flue gas temperatures of both the high and low temperature economizers increased, indicating that the fin tube economizer absorbs more heat than the bare tube economizer. After the overhaul, the exhaust gas temperature dropped significantly. This is partly due to the replacement of the slag catcher during the overhaul, which strengthened the seal of the flue wall and reduced air leakage in the boiler. Furthermore, the economizer renovation also reduced the exhaust gas temperature.

Heat transfer performance of spiral fin tube radiators. Spiral fin tubes can be divided into several types based on the process, such as serrated spiral fin tubes, slotted spiral fin tubes, and integral continuous spiral fin tubes.

Slit spiral fin tubes and solid continuous spiral fin tubes. All other conditions being equal, slit spiral fin tubes have a higher heat transfer coefficient than solid continuous spiral fin tubes. Therefore, when choosing spiral fin tubes for higher temperatures, we should choose serrated spiral fin tubes as heat exchange elements for radiators.

KL-type wound fin tubes: Before the fins are continuously wound onto the steel tube, the outer surface of the base tube is knurled. After the fins are wound, the base of the fins attached to the steel tube is also knurled to strengthen the bond between the steel tube and the fins.

This fin type ensures better heat transfer characteristics than L and LL fin types.

Operating temperature: 250°C