The heat dissipation area of the wound finned tube is relatively large: the bimetallic winding finned tube can reach 22.7 when the finning ratio is large, so the unit heat dissipation area is far beyond the conventional winding heat dissipation device.

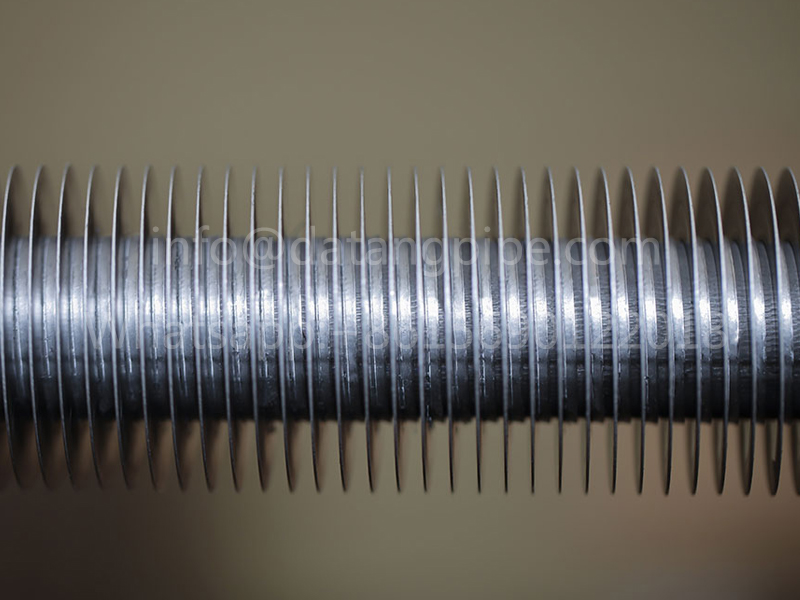

L/LL/KL Type Finned Tube for Heat Exchanger

L/LL/KL Type Finned Tube is a finned tube made of aluminum fin tape or copper fin tape folded into an L-shaped spiral under tension and wrapped tightly around the outer surface of the base tube.

The tension in the fin strips of the L/LL/KL Type Finned Tube wraps around the tube, causing the fin feet to press forcefully against the tube, holding the fins firmly in place. L Type Finned Tube is usually used in air coolers in petrochemical, power, paper, tobacco, building heating and other industries as well as heat exchangers in power plants (electricity, nuclear, thermal and geothermal power plants), the maximum operating temperature can reach 230°C.

L Type Finned Tube for Heat Exchanger Quick Details:

Fin type: Solid plain

Fin Tube Type:L Type

Outer diameter (OD): 16mm Min~50.8mm max.

Tube length: up to 18,000 mm.

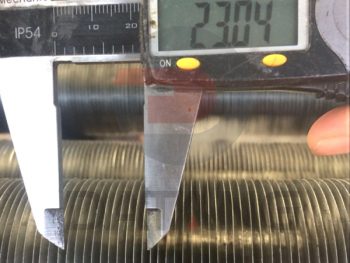

Fin height: 16.5mm max.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required