Project Description

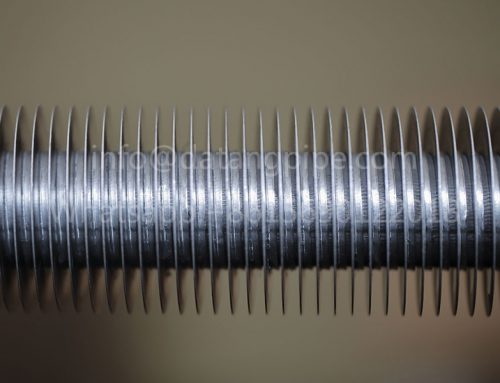

Hot dip galvanization Wavy Form Fin Tube

- Leave Your Message

Hot dip galvanization Wavy Form Fin Tube(Оцинкованная труба с волнистыми ребрами)

In Datang special machine designed for continuous Spiral Finned Pipe production, the flat fin on the pipe is given a wavy form and the plastering process is carried out. Hot dip galvanization Wavy Form Fin Tube has a turbulence feature due to its structure. It is preferred to increase heat conduction in gases with poor heat conduction such as flue gas. In case carbon steel pipe and carbon steel fin are preferred in our production, we recommend hot dip galvanization to our customers.

Hot dip galvanization Wavy Fin Tube

Hot dip galvanization Wavy Form Fin Tube-datang

Hot dip galvanization Wavy Form Fin Tube

Fin Materials

Carbon Steel, Stainless Steel

Pipe Materials

There is no theoretical limit.

Pipe Dimensions

16mm – 60.30mm

Fin Height

8mm – 20mm

Pitch

2.5mm – 10mm

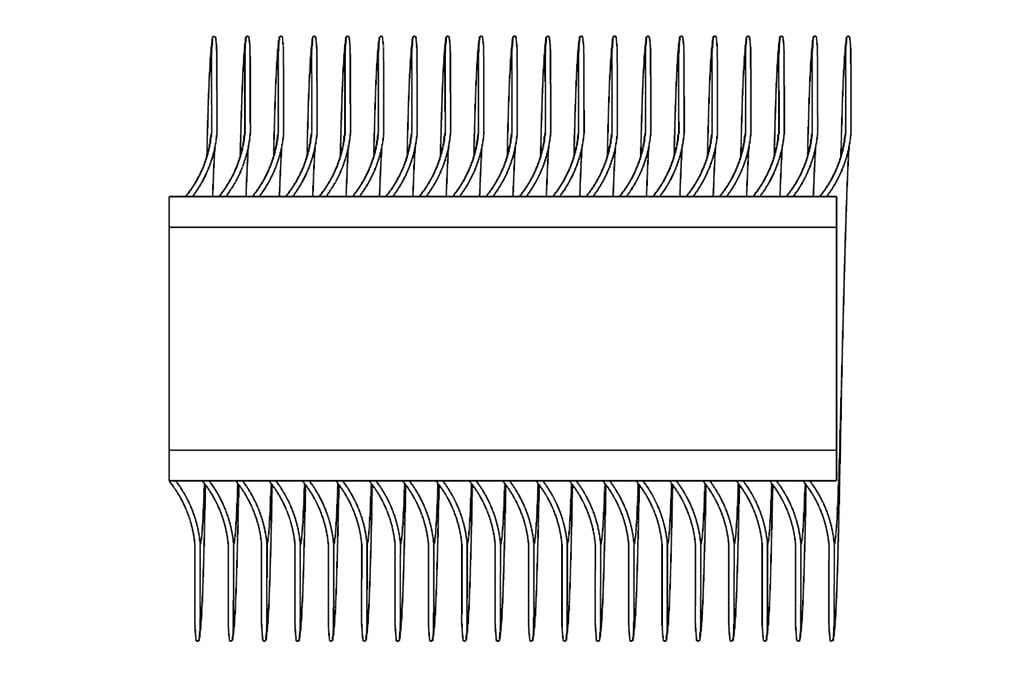

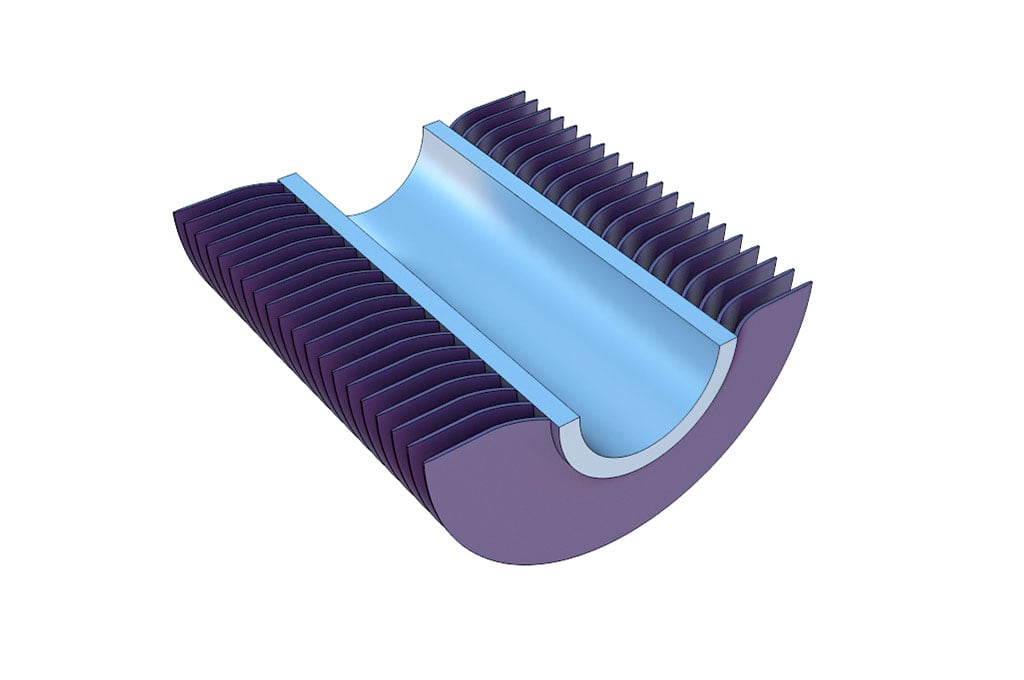

Wavy Form Fin Tubes drawing

Wavy Form Fin Tubes

Hot dip galvanization Wavy Form Fin Tube

Maximum Operating Temperature

150 ºC for Carbon Steel, Carbon Steel Hot Dip Galvanized 360 ºC

Atmospheric Corrosion Resistance

Acceptable.

Mechanical Resistance

High

There are two main reasons for this: To protect the products against corrosion and to perfect the heat transfer between the fin and the tube.

Advantages and Disadvantages of Wavy Form Fin Tubes;

Its cost is lower than L, LL and G Forms.

Resistance to air is high.

Turbulence increases heat transfer.

It is necessary to clean regularly or use a filter due to its ability to hold dust and similar things.

Types of finned tubes produced by Datang

Fin tube Inspection Packing

Our Certificates-Datang Fin Tube

Exhibition Photos-Datang Fin Tube