Project Description

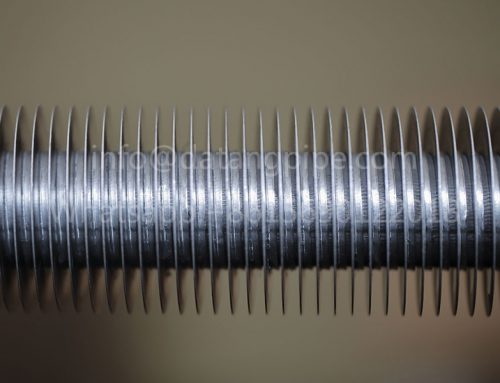

Product Name: ASTM A179 L Type Finned Tube

- Leave Your Message

ASTM A179 L-Type finned tubes are low-carbon seamless steel tubes designed specifically for heat exchangers and condensers. The base tube is made of carbon steel, and the fins are made of aluminum. The L-shaped structure is achieved through a winding process.The L-shaped design optimizes heat transfer efficiency and space utilization.

1. ASTM A179 L-Type Finned Tube Materials and Performance

Made of carbon steel, in compliance with the American ASTM A179/ASME SA179 standards, the chemical composition is strictly controlled for carbon (0.06%-0.18%) and manganese (0.27%-0.63%) content, and sulfur and phosphorus impurity content is ≤0.035%. Mechanical properties include:

Tensile strength ≥ 325 MPa

Yield strength ≥ 180 MPa

Elongation ≥ 35%

Stable operating temperature range -50°C to 450°C.

Formed using a cold-drawn process, the tubes boast a wall thickness accuracy of ±0.1 mm and a high surface finish. Heat-treated at temperatures exceeding 650°C for stress relief, the tubes have passed multiple tests, including hydrostatic and expansion tests.

2. ASTM A179 L-Fin Tube Structure and Processing

Base Tube: Seamless, cold-drawn, low-carbon steel tube conforming to ASTM A179, with an outer diameter typically ranging from 21 mm to 325 mm.

Fin Type: L-shaped wrapped fins, with aluminum fins mechanically wound onto the base tube surface to enhance heat transfer efficiency.

Fin Parameters: Fin height approximately 12.5 mm, thickness 0.5 mm, tube spacing 50 mm, and a high fin ratio (the ratio of surface area per unit length to base tube surface area).

3. ASTM A179 L-Finned Tube Performance Characteristics

Temperature Resistance: Maximum operating temperature is 150°C (limited by aluminum fins), suitable for medium and low-temperature heat exchange applications.

Heat Transfer Efficiency: L-shaped fins improve heat transfer performance by increasing contact area and creating turbulent flow, making them particularly suitable for air coolers (ACs).

Pressure Rating: Nominal pressures can range from 10 to 320 kgf/cm², depending on the tube bundle design.

4. ASTM A179 L-Finned Tube Applications

Industrial Heat Exchange: Widely used in condensers, heat exchangers, and boiler systems in refineries and chemical plants.

Air Cooler Tube Bundles: Serving as core components in forced-draft or induced-draft air coolers, they are suitable for applications in oil and gas gathering and transportation, power generation, and other industries.

5. ASTM A179 L-type Finned Tube Alternatives

Similar products include the LL type (170°C temperature resistance), the KLM type (250°C temperature resistance), and the G type inlaid finned tube (670°C temperature resistance). The selection should be based on the required temperature.