Project Description

- Product Name: Copper Nickel 90 / 10 KL Footed Aluminum Fin L LL KL Type Fin Tube

- Leave Your Message

Here is the professional of the technical specifications and application details for Copper-Nickel 90/10 (UNS C70600/B10) KL/L/LL/G-Type Finned Tubes, incorporating industry standards and process characteristics:

I. Core Material Properties

-

Copper-Nickel 90/10 Alloy (UNS C70600)

- Composition: Cu 90%, Ni 10%, with Fe (1%-1.8%) and Mn (≤1%) added for enhanced strength. Impurities (Pb, Zn) strictly controlled at ≤0.05%1112.

- Performance:

- Excellent seawater corrosion resistance (ideal for marine platforms/ship heat exchangers);

- Tensile strength ≥790 MPa, high yield strength, working pressure ≤32 MPa;

- Thermal conductivity similar to carbon steel; thermal expansion coefficient comparable to stainless steel.

-

Base Tube Requirements

- Seamless Cu-Ni tubes per ASTM B466. Wall thickness tolerance ≤±0.05 mm; straightness deviation ≤4 mm/full length.

- Alloy steel tubes require spectrochemical testing per tube to ensure compositional consistency.

II. Fin Tube Types & Manufacturing Processes

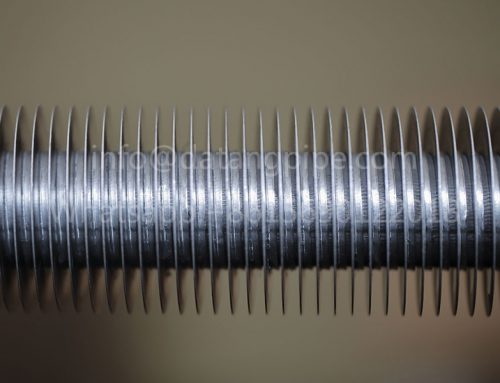

(1) KL-Type (Knurled Fin Tube)

- Process: Base tube pre-knurling → Aluminum fin winding → Secondary root-rolling for enhanced bonding;

- Features:

- 50% larger contact area vs. L/LL types → lower contact thermal resistance;

- Resists thermal cycling shock (operating temp ≤250°C);

- Wrinkle-free fins with reduced fouling risk.

(2) L/LL-Type (Wound Fin Tubes)

- L-Type: High-tension winding (fin roots untreated). Max temp: 120°C;

- LL-Type: Optimized winding tension → uniform fin pitch. Max temp: 230°C;

- Shared Traits:

- High finned area ratio (5–8× increased surface area);

- Fin thickness: 0.1–0.5 mm; pitch: 1.5–3 mm (design adjustable).

(3) G-Type (Embedded Fin Tube)

- Process: Spiral grooving on base tube → Aluminum strip insertion → End welding;

- Advantages:

- High fin rigidity → superior deformation resistance;

- Pressure rating ≤32 MPa (ideal for high-pressure heat exchange).

III. Key Technical Requirements

-

Fin Parameters

- Height: 5–30 mm (typical: 15–25 mm);

- Pitch: 15–30 mm (too small ↑ resistance; too large ↓ efficiency);

- Thickness: Al fins 0.2–0.5 mm; Steel fins 0.5–0.8 mm.

-

Tube-Fin Bond Quality

- High-frequency welding fusion rate ≥90% (tested via 8-point longitudinal sectioning);

- Embedded fins: Groove-strip gap ≤0.3 mm to prevent springback/loosening.

-

Corrosion Protection & Maintenance

- Anodized fin surfaces for enhanced marine atmospheric corrosion resistance;

- Regular fin cleaning to maintain thermal efficiency.

IV. Typical Applications

- Marine & Offshore: Ship boilers, desalination evaporators (Cl⁻ corrosion resistance);

- Energy Industry: Power plant air coolers, waste heat recovery (KL-type for ≤250°C);

- Petrochemicals: Oil/gas heat exchangers, FGD systems (G-type for high pressure).

V. Selection Guidelines

- High-Temp (>200°C): Prioritize KL-type for thermal stability;

- Corrosive Environments: Combine Cu-Ni base tube + Al fins (balance conductivity/corrosion resistance);

- Customization: Provide media temp/pressure/flow rate to optimize fin pitch/height.