Project Description

- Product Name: L-foot Tension Fin Tubes for Heat Exchanger

- Leave Your Message

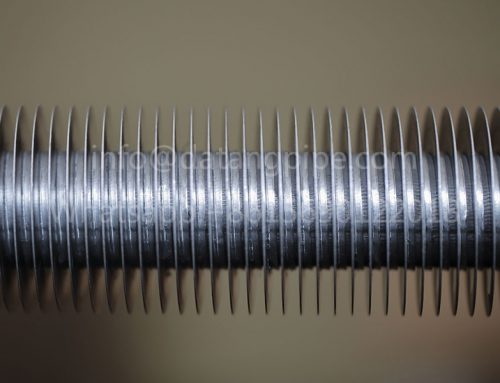

L-Foot Tension Fin Tubes: An Advanced Heat Transfer Solution

1. What is an L-Foot Tension Fin Tube?

An L-foot tension fin tube is a specialized type of finned tube designed for enhanced heat transfer efficiency. Unlike standard tension-wound fin tubes, this variant features an “L”-shaped foot at the base of each fin, which ensures superior mechanical bonding and thermal conductivity. The L-foot design provides:

- Stronger mechanical grip on the base tube, preventing fin loosening under thermal cycling.

- Improved heat conduction due to increased contact area between the fin and tube.

- Better corrosion resistance, as the L-foot minimizes gaps where moisture or corrosive agents could accumulate.

Common materials include aluminum fins on carbon steel, stainless steel, or copper tubes, making them suitable for high-temperature and corrosive environments.

| No. | Parameter | Materials / Dimensions |

|---|---|---|

| 1 | Tube materials | Carbon steel, stainless steel, copper, or aluminum |

| 2 | Tube dimensions | Outer diameter: 12.7 mm (0.5 in) to 38.1 mm (1.5 in) Wall thickness: 0.8 mm (0.03 in) to 2.5 mm (0.1 in) |

| 3 | Fin materials | Aluminum or copper |

| 4 | Fin height | 6 mm (0.24 in) to 16 mm (0.63 in) |

| 5 | Fin thickness | 0.15 mm (0.006 in) to 0.25 mm (0.01 in) |

| 6 | Fin spacing | 1.5 mm (0.06 in) to 3.0 mm (0.12 in) |

| 7 | Fin pitch | 2.0 mm (0.08 in) to 5.0 mm (0.2 in) |

| 8 | Fin angle | 18 degrees to 26 degrees |

| 9 | Tension strip material | Carbon steel or stainless steel |

| 10 | Tension strip dimensions | Thickness: 0.6 mm (0.02 in) to 1.2 mm (0.05 in) Width: 6 mm (0.24 in) to 12 mm (0.47 in) |

2. L-foot Tension Fin Tubes Manufacturing Process

The production of L-foot tension fin tubes involves precision engineering:

- Base Tube Preparation: The tube (typically carbon steel or stainless steel) is cleaned and prepped.

- Fin Strip Formation: A metal strip (usually aluminum) is pre-formed into an L-shaped profile.

- High-Tension Winding: The L-foot fin is wound helically around the tube under controlled tension, ensuring a tight mechanical bond.

- Final Inspection: Each tube undergoes quality checks for fin adhesion, spacing, and thermal performance.

3. L-foot Tension Fin Tubes Key Advantages

- Enhanced Durability: The L-foot design resists vibration and thermal expansion stresses.

- Higher Heat Transfer Efficiency: The increased contact area improves thermal conductivity by 10–15% over standard tension-wound fins.

- Reduced Fouling: The smooth helical fin layout minimizes particulate buildup.

- Lower Maintenance Costs: Long service life with minimal cleaning requirements.

4. L-foot Tension Fin Tubes Applications

- Power Plants: Used in air-cooled condensers and heat recovery steam generators (HRSGs).

- Oil & Gas: Deployed in heat exchangers for refineries and offshore platforms.

- Chemical Processing: Ideal for corrosive fluid heating/cooling due to material versatility.

- HVAC & Refrigeration: Enhances efficiency in industrial chillers and condenser coils.

L-foot Tension Fin Tubes Conclusion

L-foot tension fin tubes represent a high-performance evolution of finned tube technology, offering superior thermal efficiency, durability, and corrosion resistance. Their unique design makes them indispensable in industries demanding reliable heat transfer under extreme conditions.