Project Description

- Product Name: Wrap-On Fin Tubes for Heat Exchanger

- Leave Your Message

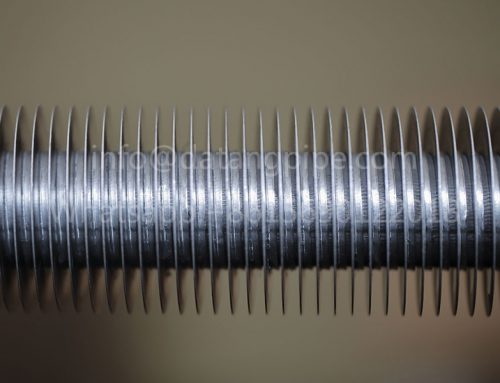

Wrap-On Fin Tubes: Enhanced Heat Transfer Technology

Definition and Manufacturing Process

Wrap-on fin tubes (also termed tension-wound fin tubes or L-foot tension fin tubes) feature a distinctive helical fin structure mechanically bonded to the base tube through tension winding. A tension strip wraps the fin material around the tube at precise angles (typically 18°–26°), creating compressive forces that ensure optimal thermal contact between fin and tube. This method eliminates air gaps, significantly enhancing heat transfer efficiency while maintaining structural integrity under thermal cycling.

| No. | Parameter | Materials / Dimensions |

|---|---|---|

| 1 | Tube materials | Carbon steel, stainless steel, copper, or aluminum |

| 2 | Tube dimensions | Outer diameter: 12.7 mm (0.5 in) to 38.1 mm (1.5 in) Wall thickness: 0.8 mm (0.03 in) to 2.5 mm (0.1 in) |

| 3 | Fin materials | Aluminum or copper |

| 4 | Fin height | 6 mm (0.24 in) to 16 mm (0.63 in) |

| 5 | Fin thickness | 0.15 mm (0.006 in) to 0.25 mm (0.01 in) |

| 6 | Fin spacing | 1.5 mm (0.06 in) to 3.0 mm (0.12 in) |

| 7 | Fin pitch | 2.0 mm (0.08 in) to 5.0 mm (0.2 in) |

| 8 | Fin angle | 18 degrees to 26 degrees |

| 9 | Tension strip material | Carbon steel or stainless steel |

| 10 | Tension strip dimensions | Thickness: 0.6 mm (0.02 in) to 1.2 mm (0.05 in) Width: 6 mm (0.24 in) to 12 mm (0.47 in) |

Wrap-On Fin Tubes Key Advantages

- High Thermal Efficiency: Tension-induced contact reduces interfacial thermal resistance, improving heat transfer rates by up to 40% compared to conventional finned tubes.

- Fouling Resistance: Helical spacing prevents particulate accumulation in fluid streams.

- Mechanical Durability: Vibration-resistant design withstands thermal stress and mechanical loads.

- Corrosion Mitigation: Tight fin-to-tube adhesion minimizes crevice corrosion risks.

Wrap-On Fin Tubes Industrial Applications

Dominantly deployed in:

- Air-cooled heat exchangers for power plants and refineries

- Compressor cooling systems in industrial refrigeration

- Waste heat recovery units in chemical processing

Wrap-On Fin Tubes Material Synergy

Aluminum fins paired with carbon steel tubes offer cost-effective corrosion resistance, while copper/stainless steel combinations excel in high-purity applications. The tension strip’s material (carbon/stainless steel) is selected to match the tube’s thermal expansion coefficient, ensuring sustained interfacial pressure.

Wrap-On Fin Tubes Performance Limitations

Despite superior thermal performance, manufacturing complexity results in higher costs than extruded or embedded fin alternatives. Additionally, fin height exceeding 16 mm may compromise mechanical stability in high-velocity flows.

Wrap-On Fin Tubes Innovations

Hybrid designs combining tension winding with knurled tube surfaces (KL fin tubes) enhance bond strength for extreme-temperature applications. Nano-coatings on fins further improve corrosion resistance in aggressive environments.

Wrap-on fin tubes remain indispensable for industries prioritizing heat transfer efficiency, reliability, and low maintenance. Their design evolution continues to address thermal engineering challenges in energy-intensive sectors.