Project Description

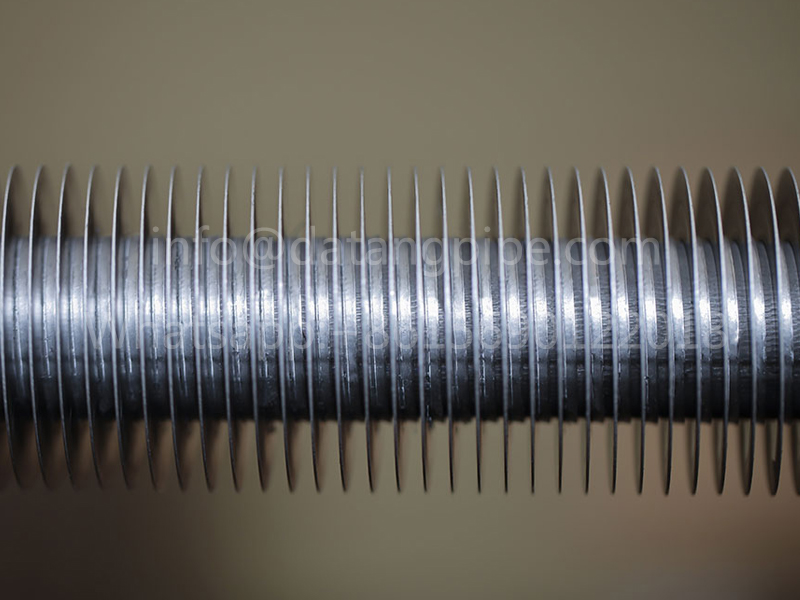

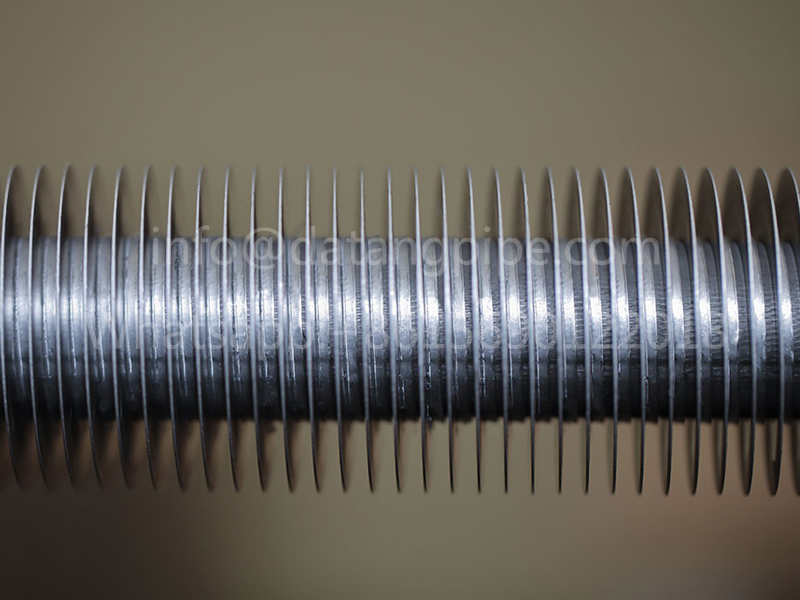

KL Type Seamless Fin Tube With Aluminum Fin For Heat Exchanger

- Leave Your Message

KL Type Seamless Fin Tube With Aluminum Fin For Heat Exchanger

Description:

Datang as one of the leading suppliers in China to supply KL Type Seamless Fin Tube With Aluminum Fin For Heat Exchanger etc.

We will guarantee that you receive a high-quality product at a highly-competitive price.

Product Range:

Finned Tube OD: ø25-ø88 mm

Fin Thickness: 0.25-0.45 mm

Fin pitch: to your requirement

Fin material: Aluminium

Base tube material: Any metallic material

KL type fin tube: Before the fins are continuously wound on the surface of the steel tube, the outer surface of the base tube needs to go through a knurling process; after the fins are wound, the roots of the fins attached to the steel tube will also be knurled to strengthen the combination of the steel tube and the fins. For this reason, this type of fin ensures better heat transfer characteristics than L and LL fins.

Application scope and characteristics of KL type wound fin tube:

Use temperature ≤280°C b. Use pressure ≤32MPa

Advantages of KL type fin tube:

1. High heat transfer performance.

2. The fins have good rigidity and are not easy to deform.

3. The outer tube has good atmospheric corrosion resistance and is stable for long-term use

Working temperature of KL type fin tube: 120℃ Features: Using winding process, the tube sheets are tightly combined, the sheet spacing is uniform, the folds are small, and it is not easy to accumulate dust.

Application of KL fin tube: Mainly used in industrial and civil heating radiators and air heaters for material drying

KL fin tube is also called knurled fin tube. Before winding the fin, knurling is first done on the base tube, or a blade is added to the winding machine to knurl the base tube. The blade behind is used for winding, and knurling and winding are carried out simultaneously.

This fin tube has the advantages of high heat transfer performance, good fin rigidity, not easy to deform, and good atmospheric corrosion resistance outside the tube.

KL fin tube has a wide range of applications, including but not limited to air coolers, air heaters in petrochemical, electric power, papermaking, tobacco, building heating and other industries, and spray drying systems in the food industry.

KL fin tube is also used in integrated air conditioning units, refrigeration and cooling machines, induced air conditioners, textile printing and dyeing machinery, forestry, chemical industry, national defense, medicine, food, starch, beer, construction and other industries, for warm cooling (enthalpy reduction, temperature reduction), dry cooling (isohumidity reduction) and heating of air.

Manufacture:

A core tube is fitted into an aluminium primary tube. This assembly is then fed into the triple-spindle finning machine. Three special multi-disc packs extrude the aluminium tube into helical high fins while reducing the inner diameter to give firm pressure contact with the core tube.