Project Description

- Product Name: Tension Wound Fin Tubes for Heat Exchanger

- Leave Your Message

Tension Wound Fin Tubes: Engineering and Applications

Definition and Structure

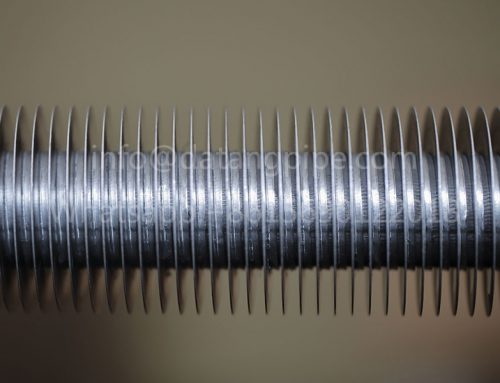

Tension wound fin tubes, also termed edge tension fin tubes or wrap-on fin tubes, feature helical metal fins mechanically bonded to a base tube under high tension34. This design creates a robust interference fit without welding or soldering, enhancing thermal conductivity and structural integrity. The fins—typically aluminum or copper—are wound at precise angles (18°–26°) to optimize heat transfer efficiency.

Tension Wound Fin Tube Manufacturing Process

- Base Tube Preparation: Carbon steel, stainless steel, or copper tubes form the core structure5.

- Fin Attachment: Aluminum or copper strips are helically wound under controlled tension, ensuring uniform contact pressure.

- Customization: Fin geometry (height, pitch, thickness) is adjustable to meet specific thermal or mechanical requirements.

Tension Wound Fin Tube Key Advantages

- Enhanced Heat Transfer: Extended fin surface area increases thermal efficiency by up to 8× compared to bare tubes.

- Corrosion Resistance: Aluminum fins protect against oxidation in harsh environments.

- Low Fouling: Helical design minimizes particulate accumulation in fluid systems.

- Mechanical Durability: Tension winding prevents fin loosening during thermal cycling.

Tension Wound Fin Tube Industrial Applications

- Air-Cooled Heat Exchangers: Widely deployed in power plants and compressor cooling systems.

- Oil & Gas: Heat recovery units and economizers.

- HVAC Systems: Enhances efficiency in air handlers and condensers.

Tension Wound Fin Tube Technical Specifications

Common design parameters for tension wound fin tubes include:

Table 1: Standard Specifications

| Parameter | Typical Range |

|---|---|

| Tube Outer Diameter | 12.7 mm (0.5 in) – 38.1 mm (1.5 in) |

| Tube Wall Thickness | 0.8 mm (0.03 in) – 2.5 mm (0.1 in) |

| Fin Height | 6 mm (0.24 in) – 16 mm (0.63 in) |

| Fin Thickness | 0.15 mm (0.006 in) – 0.25 mm (0.01 in) |

| Fin Spacing | 1.5 mm (0.06 in) – 3.0 mm (0.12 in) |

| Fin Pitch | 2.0 mm (0.08 in) – 5.0 mm (0.2 in) |

Note: Materials, dimensions, and tension strip properties (carbon/stainless steel, 0.6–1.2 mm thickness) are customizable per application demands.

Tension Wound Fin Tube Performance Considerations

Testing under steady-state and cycling conditions confirms superior heat transfer rates and mechanical resilience. However, manufacturing costs may exceed other fin types (e.g., extruded fins), limiting use in budget-sensitive projects.

Tension Wound Fin Tube Conclusion

Tension wound fin tubes deliver unmatched thermal efficiency and durability in heat exchange applications, particularly where corrosion resistance and low maintenance are critical. Their adaptable design supports diverse industrial needs, cementing their role in modern thermal management systems.

Tension wound fin tubes are a type of enhanced heat transfer tube widely used in industries requiring efficient thermal exchange. These tubes feature helical fins tightly wound under tension onto a base tube, creating a robust mechanical bond. This design significantly improves heat transfer efficiency compared to bare tubes, making them ideal for applications in boilers, heat exchangers, and air coolers.

Structure and Manufacturing Process

The construction of tension wound fin tubes involves:

- Base Tube Selection: Typically made of carbon steel, stainless steel, or copper, depending on the application.

- Fin Material: Aluminum or copper fins are commonly used due to their excellent thermal conductivity.

- Winding Process: A strip of fin material is wound under tension around the base tube, ensuring a tight fit without soldering or welding.

- Fin Pitch & Height: Customizable to optimize heat transfer for specific industrial needs.

Tension Wound Fin Tube Advantages

- Enhanced Heat Transfer: The extended fin surface area improves thermal efficiency.

- Corrosion Resistance: Aluminum fins provide protection against oxidation.

- Mechanical Durability: The tension-wound design ensures strong bonding, reducing fin loosening risks.

- Cost-Effectiveness: More economical than embedded or welded fin tubes.

Tension Wound Fin Tube Applications

- Power Plants: Used in boilers and economizers.

- Oil & Gas Industry: Employed in heat recovery systems.

- Chemical Processing: Ideal for heat exchangers handling aggressive fluids.

- HVAC Systems: Enhances air-cooling efficiency.

Conclusion

Tension wound fin tubes offer a reliable and efficient solution for industries requiring superior heat transfer. Their customizable design, durability, and cost efficiency make them a preferred choice in thermal management applications.