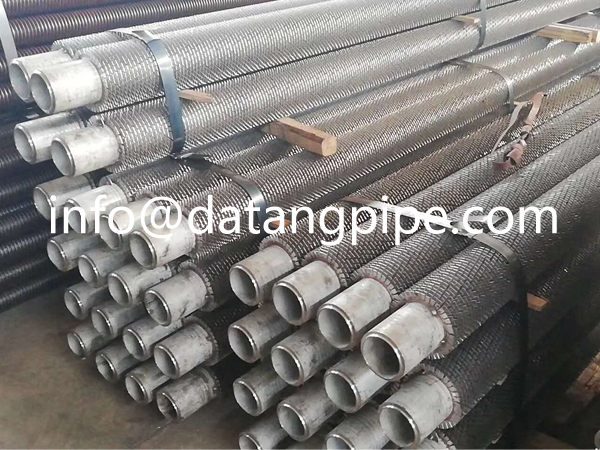

High Frequency Welding Finned Tube is also called helical high finned tube.This is to use the skin effect and proximity effect of high-frequency current to heat the outer surface of the steel strip and the steel tube until the plastic state or melting, while the steel strip is wound around the steel tube, under a certain pressure of the winding steel strip.

High frequency welded fin tube extendheat transfer surface that provides maximum efficiency in theat exchange applications from exhaust hot gas to a contained liquid process.

Both solid and serrated fin tube is used for Heat recovery steam generator, Petrochemical, Boiler Plants, Economnizer, Gas cooler and Heat exchangers in a wide range of applications.

Solid fin tube is recommened for contaminated gas streams where oil, coal, wood or other high fouling fuels are used. Serrated fin tube is primarily used in clean streams.

High Frequency Welded fin tube also called solid type fin tube,use steel or stainless steel strip directly welded to tube surface by HFW.Can improving heat transfer efficiency much more than bare tube.Due to the tight welding of the fins to the base tube, these finned tubes are often used in vibrating conditions.Fin type have Serrated fin and flat fin.

Base tube material:

stainless steel, carbon steel, alloy steel

ASME SA213/ASTM A213 TP304/304L TP316/TP316L TP321 TP310S TP317,

ASME SA106/ASTM A106 Gr B Gr C,ASME SA179/ASTM A179,ASME SA192/ASTM A192

Fin material:

Alloy steel, Stainless steel High Frequency Welded fins tube, carbon steel High Frequency Welded fins tube Duplex High Frequency Welded fins tube super duplex High Frequency Welded fins tube Air cooler fins tube, Air preheater fins tube.

Base pipe O.D: 15.88-165mm

Fin height: 6-50mm

Fin thickness: 0.3-0.5mm

Fin pitch: as customer’s request.

End: Plain Ends, Beveled Ends

No fin area on both side: As Customer’s request and drawing