Project Description

Galvanized Finned Tube–Spiral Wound Finned Tube

- Leave Your Message

What is galvanized wound fin tube

Galvanized Finned Tube–Spiral Wound Finned Tube

Galvanized fin tubes are formed by winding steel strips evenly and tightly on seamless steel base tubes, and then galvanized to improve their heat dissipation performance and corrosion resistance.

This treatment not only saves energy, but also meets environmental protection requirements. The design of galvanized fin tubes greatly increases the heat dissipation area, improves the heat dissipation efficiency, and helps maintain the stable operation of the system.

Hot-dip galvanizing can effectively prevent oxidation and corrosion on the surface of steel pipes, thereby improving the service life and stability of the equipment.

The amount of zinc on galvanized fin tubes is usually between 60~90μm, which ensures its good anti-corrosion performance. The more zinc liquid on the outside, the better the anti-corrosion performance. This fin tube has a simple structure, is easy to install and maintain, and greatly reduces the cost of use.

Galvanized fin tubes have become an indispensable part of many industries with their excellent performance and wide application fields.

Galvanized winding fin tube is a widely used fin tube. It adopts winding process, and galvanized strip is wound on galvanized steel pipe. Through special winding machine, the steel strip is evenly wound on the base pipe by mechanical force, and the two ends are spot welded and fixed. The steel strip has good toughness, is not easy to break, has good heat transfer effect, and uniform heat dissipation.

Hot-dip galvanized greenhouse fin tube is a process of adding high-frequency fins to the base pipe to achieve the purpose of enhancing heat dissipation.

Hot-dip galvanizing is to immerse the fin tube in zinc liquid with a temperature of about 500 degrees, so that a layer of zinc liquid adheres to the surface of the fin tube. The anti-corrosion performance of zinc liquid is unmatched by general processes. Professional hot-dip galvanizing treatment improves the antioxidant ability of the fin tube and the service life of the greenhouse fin tube.

Galvanized wound fin tube has the characteristics of beautiful appearance, double-layer anti-corrosion, low carbon energy saving, low inclusions, pure steel, strong compressive performance, long service life, etc. It can use water or steam as heat transfer medium to dissipate heat to the room by convection. Its heat dissipation efficiency can reach several times that of ordinary radiators.

Galvanized fin tube is a ribbed wall, which is widely used in power, chemical and other industrial fields.

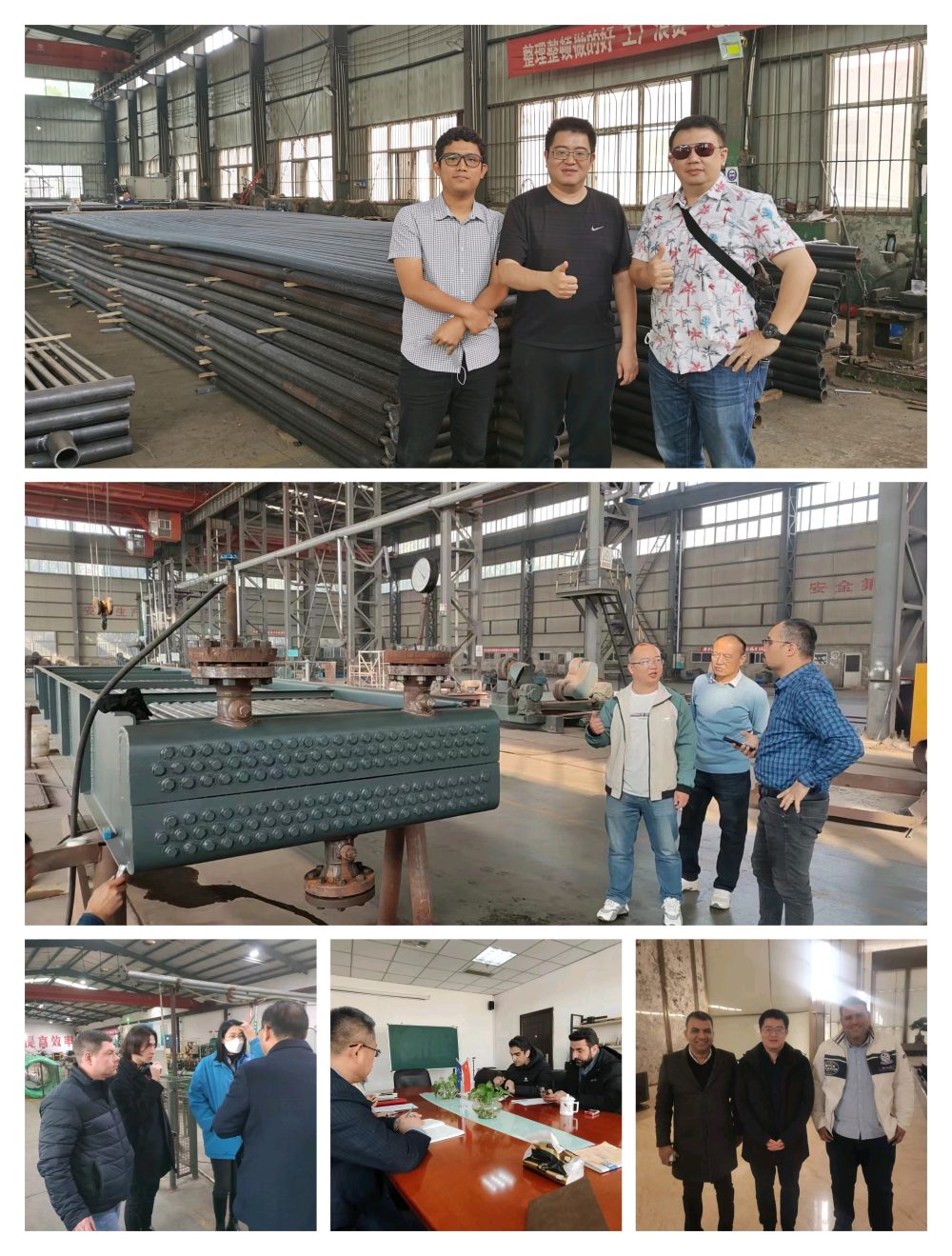

Fin tube Inspection Packing

Customer factory inspection-Datang Fin Tube

Why Choose Us

Quality Assurance Each base pipe has been tested by eddy current, ultrasonic, and hydraulic pressure, and it is ensured that each weld has no leaks. Professional Technical Service Team Every one of our technical engineers and sales managers has many years of experience working in the industry.

Fast Delivery A variety of equipment production lines to ensure faster delivery speed to meet customer requirement.

OEM/ODM Custome your Logo on prodcts and customize finned tubes and equipment according to your needs.