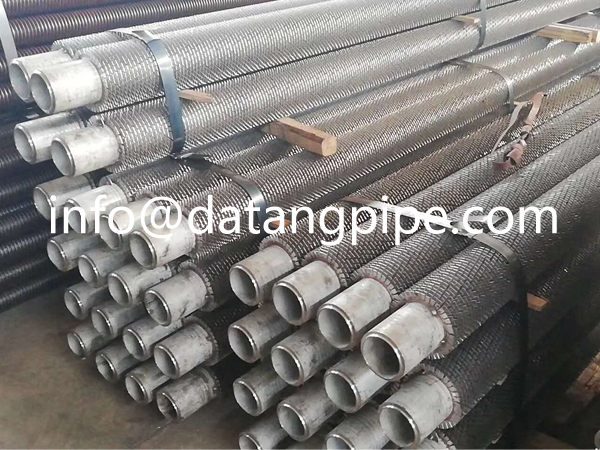

Welded fin tube is a kind of high-efficiency heat exchange element. It significantly increases the heat exchange area by welding additional fins on the surface of the base tube, thereby improving the heat transfer efficiency. It is widely used in the field of industrial heat exchange.

What is a welded fin tube?

Welded fin tube consists of a base tube and fins welded on its surface. The two are firmly connected by welding process to expand the heat exchange surface area and enhance the heat exchange performance, which is different from other fin attachment methods (such as winding or extrusion).

Main welding process types of welded fin tubes :

High-frequency welding :

High-frequency current heating is used to achieve rapid fusion of fins and base tubes, which is suitable for mass production.

Laser welding :

High-energy laser beam is used to melt the contact parts to form a metallurgical bond. The weld quality is high and the heat-affected zone is small, which can realize precise and automated production.

General welding type :

Other welding methods (such as arc welding) are included to ensure the firm connection between the fins and the base tube, which is suitable for industrial-grade durability requirements.