Project Description

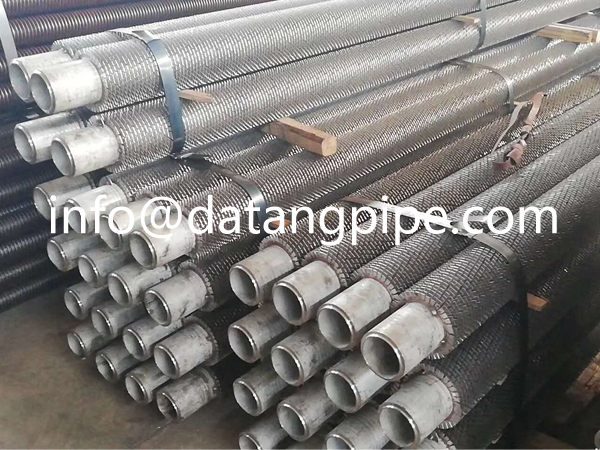

- Product Name: High Frequency Welded Spiral Serrated Fin Tubes for Power Plants

- Leave Your Message

What is a high frequency welded spiral serrated fin tube?

High frequency welded spiral serrated fin tube is a fin tube made by high frequency welding technology. Its characteristics are that one or more layers of thin metal fins are spirally welded on the surface of the base tube, and a fine tooth structure is opened on the fin, which greatly increases the heat exchange area and improves the heat conduction efficiency.

Structure and process of high frequency welded spiral serrated fin tube

High frequency welded spiral serrated fin tube heats the outer surface of the steel strip and steel tube through the skin effect and proximity effect of high frequency current, and then completes the welding under a certain pressure, so that the base tube and the fin are basically integrated. This welding method ensures that the fin and the base tube are tightly combined, without gaps and leakage, and can maintain long-term stability and durability even under high pressure, high temperature or highly corrosive conditions.

Application fields and advantages of high-frequency welded spiral serrated fin tubes

High-frequency welded spiral serrated fin tubes are widely used in various industrial fields, especially in power plants, where their advantages are particularly obvious:

High-efficiency heat transfer:

By increasing the heat exchange area and optimizing the fluid flow path, the heat transfer efficiency is significantly improved and energy consumption is reduced.

Strong adaptability:

The height, spacing and tooth shape parameters of the fins can be adjusted according to different heat exchange requirements to meet the use requirements under various working conditions.

Strong corrosion resistance:

Commonly used materials such as stainless steel, copper, and aluminum have excellent corrosion resistance and high heat transfer performance, and are suitable for various harsh environments.

Good economy:

Reduce material usage, reduce system costs, and improve equipment economy and operational reliability.

Finned tubes are heat exchanger elements that increase the heat transfer area by adding fins to the surface of the pipe. This design can significantly improve heat exchange efficiency and reduce energy loss, thereby achieving the goal of energy conservation and emission reduction.

In power plants, finned tubes are mainly used in key equipment such as boilers, steam turbines, and generators to improve the efficiency of heat transfer and reduce energy waste. Compared with traditional heat exchangers, finned tubes have higher heat transfer coefficients, lower thermal resistance, and corrosion resistance.

Practical cases of high-frequency welded spiral toothed finned tubes for power plants

In recent years, many power plants at home and abroad have begun to adopt high-frequency welded spiral toothed finned tube technology to improve the efficiency of heat source utilization and reduce operating costs.

For example, a large coal-fired power plant installed a finned tube air preheater in the flue at the tail of the boiler, which improved the thermal efficiency of the boiler, reduced the exhaust temperature, and achieved the goal of energy conservation and emission reduction.

In addition, some new energy power plants such as wind power and solar power stations have also begun to apply finned tube technology. For example, in solar water heating systems, finned tubes are used as the core components of collectors, which absorb solar heat and transfer heat energy to the working medium to drive the power generation system.

Future Prospects and Challenges

Although the application of finned tubes in power plants has achieved remarkable results, it still faces some challenges. The design and manufacture of finned tubes require high-precision technology and equipment support, and the requirements for manufacturers are high. Secondly, finned tubes may be affected by factors such as wear and corrosion during operation, and require regular maintenance and replacement.

In the future, with the continuous development of new materials and new technologies, the performance of finned tubes will be further improved. For example, finned tubes coated with nanomaterials have higher heat transfer efficiency and corrosion resistance; at the same time, the application of intelligent monitoring and maintenance systems will also provide more reliable guarantees for the stable operation of finned tubes.

As an effective and energy-saving heat exchanger element, finned tubes have important application value in power plants. By adopting finned tube technology, power plants can not only improve resource utilization efficiency and reduce operating costs, but also make positive contributions to achieving sustainable development goals. In the future, with the continuous advancement of technology and the expansion of application fields, the application prospects of finned tubes in power plants will be broader.