Project Description

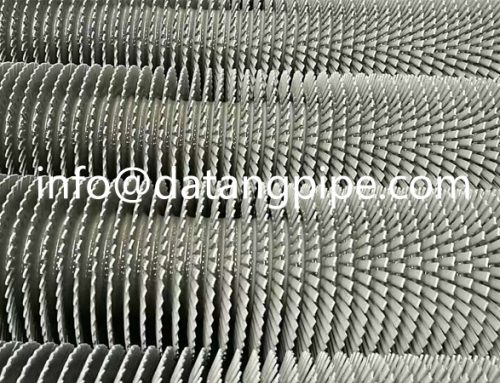

Product Name: Serrated Finned Tube Serrated Fins

- Leave Your Message

The Function of the Fin Profile of Serrated Fin Tubes

The fin profile of serrated fin tubes primarily improves heat transfer efficiency by:

Increasing the heat transfer area

The serrated fins increase the outer surface area of the tube, increasing the heat transfer area per unit length by 3-10 times compared to ordinary plain tubes, thereby improving heat transfer efficiency.

Disrupting the Boundary Layer

The serrated structure effectively disrupts air flow, breaking the thermal resistance of the boundary layer, and enhancing the convective heat transfer coefficient between the air and the fins, resulting in a 30%-80% increase in heat transfer efficiency compared to ordinary plain tubes.

Enhanced Heat Transfer Performance

The high-frequency welding process ensures a tight bond between the fins and the base tube, reducing thermal resistance. The metallurgical bond created by the high-frequency current provides a stronger and more durable structure.

Self-cleaning and Anti-fouling Properties

The serrated fins reduce dust and impurity accumulation, extending radiator life and reducing maintenance costs.

Serrated spiral fin tube radiators, a leader in high-efficiency heat exchange in modern industrial and residential buildings, feature a unique design that not only optimizes heat transfer efficiency but also demonstrates significant advantages in energy conservation and emission reduction.

The serrated fin design, like the meshing of precision gears, effectively increases the heat dissipation surface, allowing heat to be more fully exchanged with the surrounding environment during heat flow. This design reduces thermal resistance and accelerates heat transfer, maintaining stable heat dissipation performance even under high flow rates and high temperature gradients.

Furthermore, the spiral fin layout cleverly utilizes the principles of fluid mechanics to guide the fluid around the tubes into laminar or turbulent flow, further enhancing heat convection. This flow pattern not only improves heat dissipation efficiency but also reduces fluid resistance and pumping energy consumption, achieving the dual goals of energy conservation and high efficiency.

Notably, the serrated spiral fin tube radiators utilize meticulously selected materials, primarily corrosion-resistant and highly thermally conductive metals such as aluminum alloy and stainless steel, ensuring long-term stable operation in harsh environments. At the same time, precise manufacturing technology and strict quality control ensure that each fin fits tightly onto the base tube without gaps or falling off, thus ensuring the overall strength and heat transfer efficiency of the radiator.