Project Description

Helical Spiral Serrated Fin Tube For Heat Exchanger

- Leave Your Message

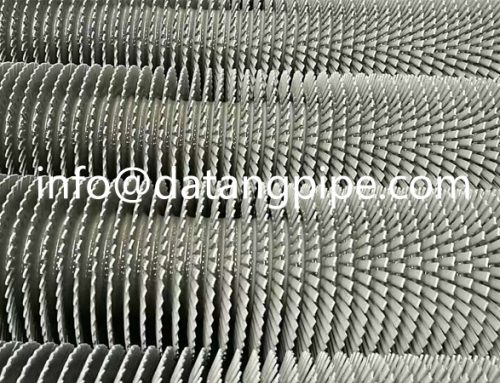

Helical Spiral Serrated Finned Tube

HFW Serrated Finned Tubes is short for High Frequency Welded Helical Spiral Serrated Finned Tubes.

Helical serrated finned tubes, serrated fins cut from a metal strip and then helically wound around the tubes.

Spiral Serrated Finned Tube For Heat Exchanger

Serrated Finned Tube is a high-frequency welding production process with high-frequency patented technology. Using high-frequency power supply as a heat source, the steel strip and steel pipe are heated at the same time, so that they can be welded together. It has the characteristics of long life, wide temperature range and high pressure tolerance.

The important features of this configuration are Efficiency, effective bond of fins to tubes under all conditions of temperature and pressure, and ability to withstand high fin side temperatures. This serrated fin configuration is even better to withstand the fin fouling if that is a problem in the application. This gives better heat transfer properties compared to solid fins.

High frequency serrated pipes are manufactured helically forming a segmented metal strip around a pipe.

The strip is welded to the pipe using high frequency electrical resistance welding (HFRW) during the forming process.

The segment metal strip produces non-parallel fins.

HFRW is faster than GMAW welding, produces a more consistent weld, allows us to weld similar and dissimilar metals and reduces the need for heat treating the finished product.

It provides a homogenous, clean, continuous bond between the metal strip used for the fins and the pipe.

HF welded spiral finned tube is the most widely used of the spiral finned tube, widely used in electric power, metallurgy, cement industry preheating collection and petrochemical industries. High-frequency spiral finned tube is welded steel strip coil pipe at the same time, using high-frequency currents of the skin effect andproximity effect of steel tube, and surface heat until melted in the plastic state or steel strip coil, the complete welding under certain pressure. This kind of high frequency welding as a solidphase welding. It with Mosaic, brazing (or whole galvanized) method, whether in product quality (fin of weld rate is high, of 95%), or the productivity and automation degree, are more advanced.

Base Tube Details:

Tubes Diameter Range: 15.88 mm to 219 mm;

Tubes Thickness Range: 1.651 mm to 16mm;

Tube Material: Carbon Steel Seamless Tubes, Stainless Steel, Carbon Alloy Steel, Corten Steel, Duplex Stainless Steel, Super Duplex Stainless Steel S32750, Inconel Alloy, High Chrome High Nickle Incoloy alloy, CK 20 material, and some other material.

Fin Details:

Fins Thickness: Min. 0.8 mm to Max. 4 mm;

Fins Height: Min 0.25´´ (6.35 mm) To Max 1.5´´ (38 mm);

Fin Density: Min 43 Fins per Meter to Max. 287 Fins per Meter;

Material: Carbon Steel, Stainless Steel, Alloy Steel, Corten steel, Duplex Steel, and Incoloy Alloy.

Helica Serrated Fin Tube Manufacturing Process:

Serrated Finned Tube use high-frequency welding production process, using high-frequency power source as heat source, to heat steel strip and steel pipe at the same time, so that they can be welded together into one

1. U-bends with longitudinal fins and fin coils are available on request.

2. Longitudinal fin types: one piece, standard U-bend, cut and twisted, perforated, etc…

3. The fin channels are welded to the tube in pairs. The fin height, number of fins, and fin thickness can be specified.

4. Fins can be used for OD pipe or NB pipe.

Serrated Finned Tube is combined with two different materials

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

Helical serrated fin pipes are used in heat recovery equipment such as economizers and chillers to process heated liquids for specialty applications.

Common applications include recovery operations associated with boilers, gas turbines used in power generation and furnaces used in petrochemical processing and refining.

Features of Serrated Finned Tube

1. Simple and economical installation. The maximum length of the sawtooth high-frequency welded spiral finned tube can reach 16 meters, which reduces the number of connection points, makes the installation more economical and quicker, and reduces the probability of water leakage at the connection.

2. Easy to maintain. After the serrated high-frequency welded spiral fin tube is installed, it is basically maintenance-free.

3. High-efficiency, sawtooth high-frequency welding spiral finned tube is full contact welding of fin and steel tube winding, the heat dissipation area is more than 8 times that of the light tube, the interior is smoother, and the internal water flow resistance is small.

4. Long service life, high mechanical strength of fins and pipes, tensile strength of more than 200Mpa, and hot-dip galvanizing treatment inside and outside the pipes.

Helica Serrated Fin Tube Application

Serrated Finned Tube is a new, wear-resistant and high-efficiency heat-exchange material. It is a high-efficiency and energy-saving heat-exchange element. It is widely used in waste heat recovery, petrochemical, power station boilers, economizers, passenger cars, industrial and civil building heating and refrigeration. , Medicine drying, wood drying, grain drying systems and other industries.