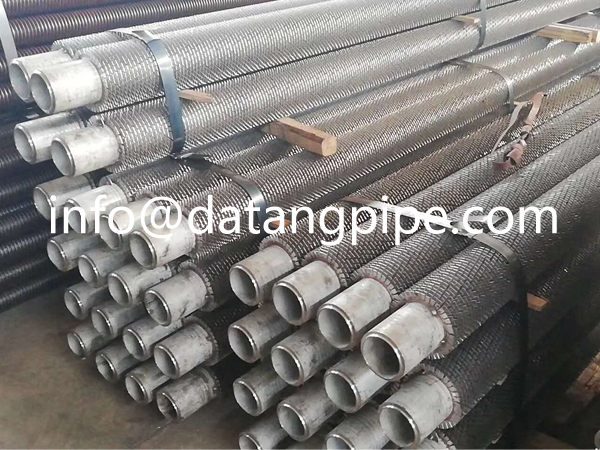

Serrated Finned Tube For Heat Exchanger

Serrated Finned Tube is a high-frequency welding production process with high-frequency patented technology. Using high-frequency power supply as a heat source, the steel strip and steel pipe are heated at the same time, so that they can be welded together. It has the characteristics of long life, wide temperature range and high pressure tolerance.

Serrated Finned Tube Quick Details:

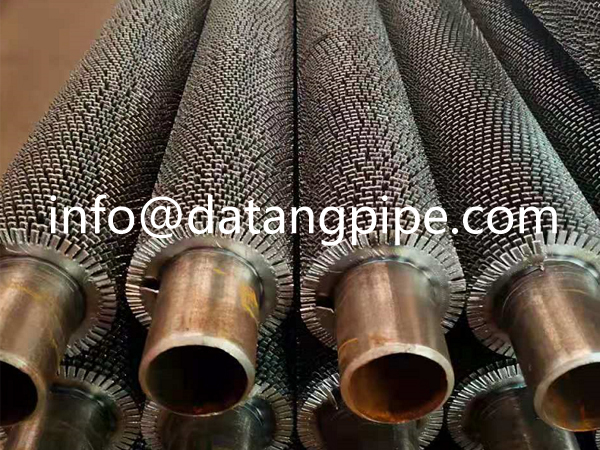

Core tube material: carbon steel, low alloy steel, stainless steel, brass, copper, copper-nickel alloy, aluminum bronze, nickel alloy.

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

4. Titanium: B338 Gr 2

Fin type: U fins,perforated,twist…

Fin material: aluminum, copper, steel

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

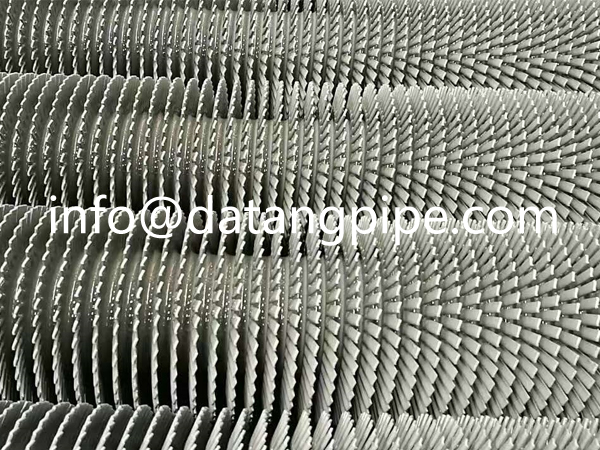

Fin Tube Type: Plain Strips

Fin number: 2/ 4/ 8/ 16/ 18/ 32/ 36 piece per row

Number of fins: 16/20/24/32/40

Tube OD: 19mm min.

Tube Length: 18 meters max.

Fin height: 16.5mm max.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).