Project Description

Wherever heat transfer is needed in industrial production processes, the elliptical fin tube has demonstrated its high efficiency in areas of application that include the following:

• Refineries

• Petrochemical industry

• Steel mills and the rest of the steel industry

• Natural-gas facilities

• Power plants

• Paper industry

• Textile industry

and others

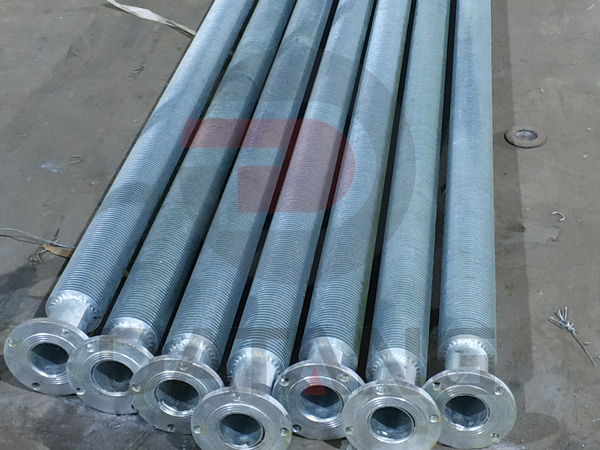

Hot dipped galvanized oval (elliptical) fin tubes with rectangular Fins ( fin tubes ) is by setting up rectangular or square-shaped fins over Oval tube.

This fin tubes (pipes) maximizes the performance of Heat Exchangers and minimizes the loss of heat transfer and pressure.

fin pitch mm 2.3 2.5 2.8 3.2

fin quantit pc/m 416-455 390-410 345-370 302-322

heat transfer area (square meter/m) 1.15 1.05 0.95 0.85

weight (Kg/m) 2.0/2.5 3.0/3.3 2.9/3.1 2.7/3.0 2.5/2.8

tube material carbon steel tubes (seamless or welded pipes)

Bare tube (mm) Long 36-0.2 Short 14-0.2

Fin material SPCC

Fin size (mm) 55*26*0.25

Zin layer (mm) 0.05-0.07

Turbulator quantity 4pcs,10 pcs or 26 pcs

length(m) 15000mm

Hot-dip galvanized finned tube has high corrosion resistance and compression resistance, and is a more popular type of finned tube, so how is it produced?

First of all, the hot-dip galvanized finned tube is on a seamless steel base tube, and the steel strip is evenly and tightly wound on the steel base tube with a winding machine specialized in the manufacture of hot-dip galvanized finned tubes. It is then sent to the galvanizing workshop for galvanizing work.

The whole tube of the hot-dip galvanized finned tube will be galvanized, so that the anti-corrosion performance of the finned tube is higher than that of ordinary steel finned tubes, even several times or dozens of times that of other steel finned tubes. The cost performance and service life of the film tube!

Hot-dip galvanized finned tubes have strong compression resistance, and are used in industry, chemical industry, petroleum industry and large workshops. In addition, the hot-dip galvanized finned tube can withstand the collision and damage encountered during transportation and reduce the loss of customers. It is a very favorite product of customers.

Fin Chip inserted Finned Tube

The fin chip inserted finned tubes made by a batch of punched single fin, and then used the manual or mechanical method, according to a certain pitch (fin pitch), by a surplus will be set on the outer surface of the base tube. It is the earliest method of processing the fin tube. Due to the simplicity of this kind of fin tubes, the technical requirements are not high, the low cost of the equipment, and easy maintenance, so, there are still many factories in the use of it. This process is a kind of labor intensive process plan, suitable for general small factory or township enterprises capital and technical conditions.

The fin chip inserted finned tubes is the use of tools, relying on the strength of manual inserte fin by fin. This method because of the pressure of the fin is limited, so the amount of interference is small, easy to produce the phenomenon of loose fin.

The mechanical set of fins is carried out on the fin set. Because the fin press is on the mechanical impact or liquid pressure, the pressure is large, so, can be used in a large amount of interference. The bond strength between fin and tube is high, and is not easy to loose. Machine driven by a high productivity, but the noise is big, the safety is poor, the workers working condition is poor. Although the hydraulic transmission of the above problems, but the higher the cost of equipment, the use of maintenance personnel of the higher technical requirements, its productivity is low.

Cangzhou Datang Steel Pipe Co., Ltd located in Cangzhou City,the hometown of pipelines, is a collection of research and development, production, sales in one of the enterprises. The company was founded in 2007 with registered capital 10.08 million RMB, and through the IS09001 international quality system certification, we has high frequency resistance welding finned tube production line 18, extruded finned tube equipment 30, laser welding finned tube production line 2, wound finned tube production line 12. The annual capacity can reach 100,000 tons, the specification φ 18-273mm finned tube, according to the customer requirements of the standard production, service has exceeded 3000+ enterprises.

Our companys tenet is to be Chinas most professional pipeline and equipment suppliers, on the basis of seamless steel tube, integrate the national high quality pipe equipment resources, provide one-stop packaging services,quality makes customer trust, service makes customer relieved, result makes customer comfort, building a conscience, good-hearted, have the sense of responsibility, contributes to the society of the enterprise.Our slogan is professional concentrate in pipeline & accessories 20 years.

Inquiry and consulting support.

Sample testing support.

Visit our factory

After-sales service

Training how to install the tubes, and maintenance.

Engineers available to service overseas.

FAQ

Are you a manufacturer?

We are a professional manufacturer focus on the fin tube area.

Does free shipping is possible?

We don’t offer a free shipping service, but we will offer a discount depends on the quantity.

Do you make OEM?

Yes, we do. We manufacture according to your design and brand standards.

How about the delivery time?

According to the sizes and quantity, delivery time is different. We transport by sea and air normally.

Maintenance

We ensure our standards against erosion and provide professional maintenance advice, for quality advice, we can guarantee for one-year after-sales.