Project Description

- Leave Your Message

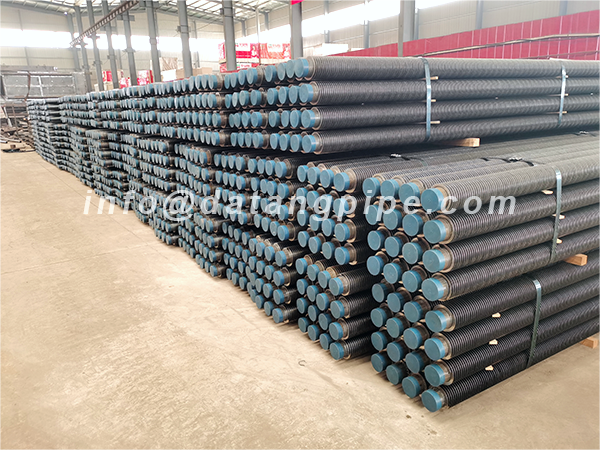

Alloy Seamless Tube High-Frequency Welded (HFW) Fin Tubes

Introduction

High-frequency welded (HFW) fin tubes using alloy seamless tubes represent advanced heat exchange technology that combines superior material properties with efficient manufacturing processes. These components are widely applied in power generation, petrochemical, HVAC and other industrial fields due to their excellent thermal performance and structural reliability.

Manufacturing Process

The production involves:

- Using high-frequency current (200-400kHz) to create skin and proximity effects

- Instantaneous heating of steel strip edges to 1200-1400°C

- Molecular-level metallurgical bonding between fins and base tube through solid-state welding

Key process advantages:

- Welding speed reaching several meters per second

- Minimal heat-affected zone

- Elimination of contact thermal resistance

Technical Parameters

ParameterSpecificationNoteBase Tube MaterialAlloy seamless tube (carbon steel, stainless steel)Preferred for leak preventionFin MaterialSteel/Aluminum strip (0.5-1.5mm thickness)Frequency Range200-400 kHzHeating Temperature1200-1400°CHeat Transfer Improvement30-50% efficiency increaseCompared to bare tubesCoverage AreaUp to 20,000 m²For space heating applications

Performance Characteristics

- Structural Advantages:

- Compact design with expanded heat transfer surface

- Enhanced stability and operational safety

- Reduced leakage probability from seamless construction

- Thermal Performance:

- Increased heat transfer coefficient

- Rapid heat dissipation capability

- Maintains comfort in large spaces

- Material Benefits:

- Excellent corrosion resistance

- High temperature endurance

- Combined strength and thermal conductivity

Alloy seamless tube high frequency welding (HFW) fin tube

Alloy seamless tube high frequency welding fin tube is welded by high frequency current with a frequency of 20wHz/s. Since high frequency current welding will produce corresponding skin effect and proximity effect, the current only passes through the surface of the radiator. Therefore, the weld of the fin tube made by this welding technology is narrow and the appearance is more beautiful.

The alloy seamless tube high frequency welding fin tube is fixed on the base tube radiator by welding to form a high frequency welding fin tube radiator.

The structure of the high frequency welding fin tube radiator has become more compact due to the addition of fin tubes, and the equipment operation is more stable, which improves the operation safety and reliability of the base tube radiator.

The alloy seamless tube high frequency welding fin tube is installed on the base tube radiator, which also increases the heat dissipation area of the original radiator and improves the heat dissipation coefficient of the original radiator. Therefore, the heat dissipation efficiency of the high frequency welding fin tube radiator is higher, and it can quickly and excellently dissipate heat in the room with an area of 20,000 square meters, improve the heat dissipation efficiency and improve the comfort of people in the room while ensuring the safety of heat dissipation.

Alloy seamless tube high frequency welded fin tube can use seamless steel tube and welded steel tube as the main raw materials, among which seamless steel tube is more popular.

Alloy seamless tube high frequency welded fin tube has less probability of water leakage and seam leakage because the raw materials used are without welds.

Datang fin tube product’s specification outside diameter from 18 mm to 273 mm finned tube, The process includes high-frequency welded fin tubes, extruded fin tubes, L / L L / K L fin tubes, G -type Embedded fin tubes, low fin tubes, inner fin tubes, elliptical fin tubes, longitudinal fin tube,H type fin tube, the annual capacity can reach 100,000 tons.

We have professional engineer support, high efficiency sales team and competitive price superiority.

Our R & D department provides the strong technical support and enables us to receive some, O D M projects, and can provide you with drawings, design plans and thermal calculations, service has exceeded more than 3000 enterprises.

If you need finned tubes, contact us! Email:info@datangpipe.com,Whatsapp:+86 15690122018