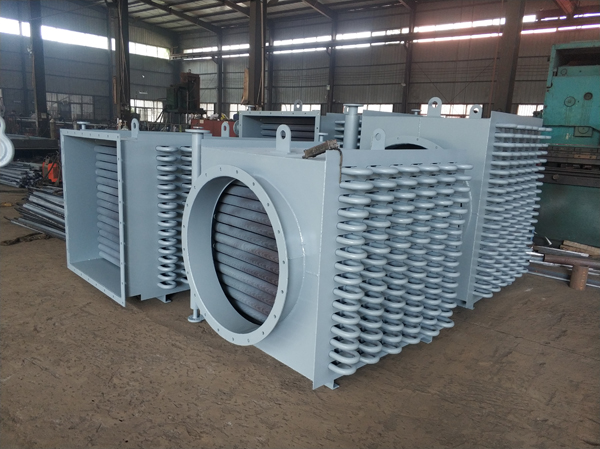

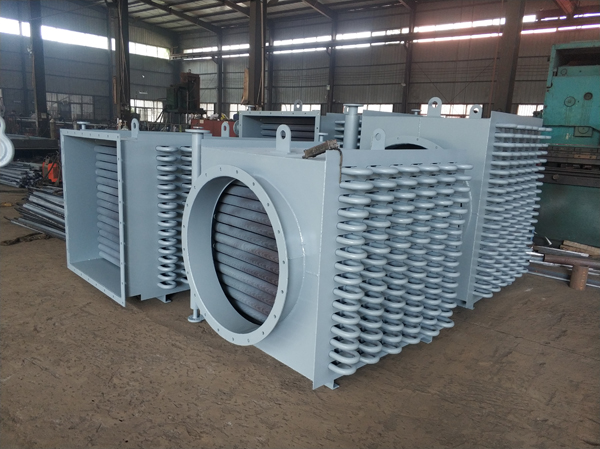

- Product Name:Fin heat exchangers are used in the drying industry

- Fin Tube Type:Carbon steel

- Leave Your Message

Drying heat exchanger is a piece of equipment widely used in industrial fields. It is mainly used to transfer heat from the heat source to the materials that need to be dried, so that the moisture in the materials can be evaporated to achieve the purpose of drying.

Drying heat exchangers have a wide range of applications, including:

Food industry: used for drying fruits, vegetables, meat, grains and other food raw materials.

Chemical industry: used for drying chemical raw materials, intermediates, products, etc.

Pharmaceutical industry: used for drying pharmaceutical raw materials, intermediates, products, etc.

Building materials industry: used for drying cement, lime, ceramics and other raw materials.

Other industries: used for drying wood, paper, textiles, etc.

The main types of drying heat exchangers are:

Fin-tube heat exchanger: Fin-tube heat exchanger is the most common type of drying heat exchanger. It has a simple structure, low price and high thermal efficiency.

Plate heat exchanger: Plate heat exchanger has the advantages of compact structure, high heat transfer efficiency, and corrosion resistance.

Shell and tube heat exchangers: Shell and tube heat exchangers have the advantages of simple structure, easy maintenance, and strong adaptability.

The selection of drying heat exchanger should be based on the following factors:

Heat source: The type, temperature, flow rate and other factors of the heat source will affect the selection of heat exchanger.

Material: The type of material, moisture content, drying temperature and other factors will affect the selection of heat exchanger.

Drying process: The type of drying process, drying time, drying temperature and other factors will affect the selection of heat exchanger.