- Product Name:Tube in tube heat exchange/Double pipe heat exchanger

- Leave Your Message

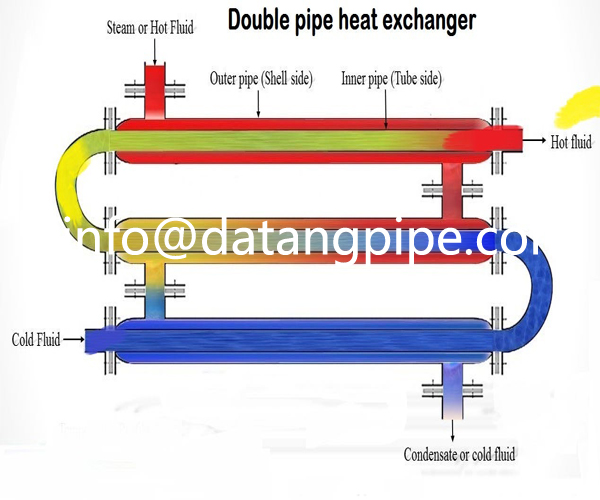

Double pipe heat exchanger is the simplest type of heat exchanger used in industry. It is used when the required heat transfer area is relatively small.

Double pipe heat exchanger consists of concentric pipes, connecting tees, return heads and return bends. The packing glands support the inner pipe within the outer pipe. A double pipe heat exchanger arranged in two legs [ i.e. when two lengths of inner pipe are connected by return bend] as shown in fig. is known as a single hair-pin heat exchanger. Tees are provided with nozzle or screwed connections for permitting the entry and exit of the annulus fluid which crosses from one leg to the other through the return head.

The return bend connects two legs of inner pipes to each other. This exchanger can be very easily assembled in any pipe — fitting shop as it consists of standard parts and it provides indexpensive heat transfer surface. In this exchanger, one of the fluids flows through the inside pipe and the other fluid flows through the annular space created between two concentric pipes either in co-current or counter -current fashion. It is usually employed for decreasing the temperature of a hot fluid with the help of a cold fluid when flow rates are low. These are commonly used in refrigeration services.

These exchangers are usually assembled in effective lengths of 3.65, 4.57, 6 meter. The distance in each leg over which the heat transfer occurs is termed as the effective lengths.

A part this, double pipe heat exchanger is very attractive where the total heat transfer surface required is small 9.29 m2 to 14 m2 or less. It is simple in construction, cheap and easy to clean.

The major advantages of double pipe heat exchanger

Sutible to high pressure application

Modular type construction

it can be welded easily

low cost in maded.