Project Description

Function and efficiency of G-type embedded fin tube for heat exchanger

- Leave Your Message

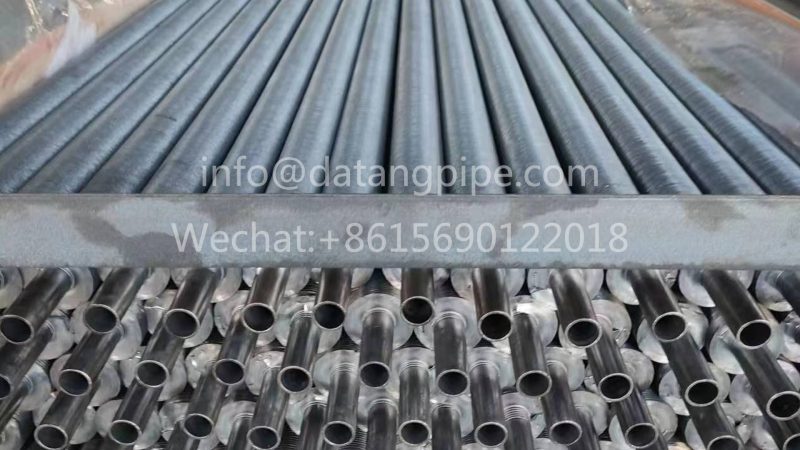

Processing technology: The fins are tightly embedded in the outer surface of the mechanically grooved base tube.

Base tube material: carbon steel, alloy steel, stainless steel, duplex steel, copper tube.

Fin: aluminum 1060, aluminum 1100, T2 copper

Occasions of use: air cooler, heat exchanger, heater, economizer

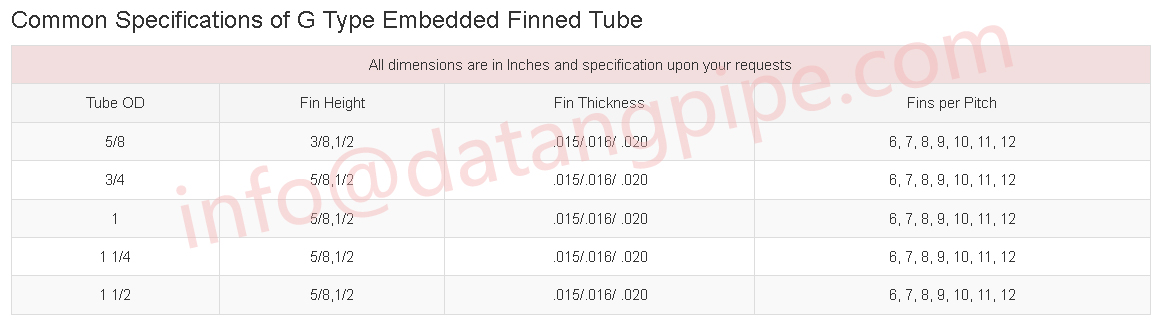

Specifications of G-type embedded fin tube for heat exchanger

Application areas:

●Petroleum, chemical and petrochemical industries

●Natural gas processing

●Steel industry: blast furnace and converter system

●Power generation: exhaust gas condensation from steam turbines, condensate contact cycle cooling condensation, fossil and nuclear power plants

●Air conditioning (Freon, ammonia, propane)

●Waste incineration equipment

●Compressor cooler, etc.

G fin tube for heat exchang manufacturerer-Datang Fin Tube

Function and efficiency of G-type embedded fin tube

Increase the outer surface area or inner standard area of the heat exchange tube, so as to achieve the purpose of improving the heat exchange efficiency of the fin tube.

G-type embedded finned tube is a wear-resistant, new and efficient heat exchange material. It is an energy-saving heat exchange element when used. The equipment mainly uses high-frequency power as the heat source, which can heat the steel pipe and steel strip at the same time, so that they can be welded into one.

G fin tube manufacturerer-Datang Fin Tube

G-type embedded finned tube has the advantages of high heat exchange efficiency, large heat dissipation area, long product service life and wide temperature range. The product is widely used in industrial fields such as petrochemical, economizer, waste heat recovery, greenhouse, power station boiler, wood drying, etc.

G-type embedded finned tube is easy to install and economical. It reduces the connection points, making the equipment installation more economical and quick, and to some extent reduces the probability of water leakage at the connection. The product is easy to maintain and basically does not require maintenance after installation.

G-type embedded finned tube has high use efficiency. The steel pipe and fin are wound and fully contact welded during the production process. The heat dissipation area is more than 8 times that of the light tube. The inside of the product is smoother and the internal water flow resistance is relatively small.