Project Description

G’ Fin Tubes or Embedded Fin Tubes are mainly used in air fin coolers and many different types of air-cooled radiators. These types of ‘G’ Fin Tubes mainly find application in areas where the temperature for heat transfer is in a slightly higher range. The Embedded Fin Tubes are mainly used in places with higher temperature and where the working atmosphere is relatively less corrosive to the base tube.

Main industries in which the ‘G’ Fin Tubes find service are Process Chemical Plants, Refineries, Gas Processing Plants, Steel Plants, Power Plants, Fertilizer Manufacturing Plants, etc.

Fins Per Inch:5-13 FPI

Fin Height:0.25″ to 0.63″

Fin Material: Cu, Al

Tube OD:0.5″ to 3.0″ OD

Tube Material:Cu, CuNi, Br, Al, SS, CS, Ni, Ti

Max Process Temperature:750 °F

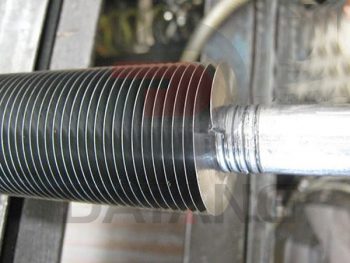

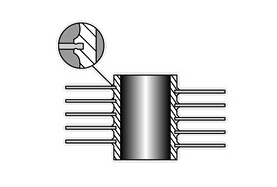

Finned Tube—-G-Type Fintube / Embedded Fintube

A spiraling groove zero.2-0.3 mm (0.008-0.012 in) is plowed into the surface of the base-tube wall such metal is just displaced, not removed. The metal fin is wound automatically into the groove beneath tension, once that the displace metal is rolled back on all sides of the fin to carry it in situ. that’s why this sort is additionally referred to as embedded finned tube. The emotive thickness of the base-tube wall is that the thickness at a lower place the groove. this sort provides wonderful contact, each thermal and mechanical, between fin and groove. though the base-tube metal is exposed to the atmosphere, tests beneath server conditions showed that corrosion over an extended amount is needed before any bond weakness happens.

The G-type fin tube is applicable to warmth up to 750 F degree (450 C degree)

Application:

Oil and gas refineries

Petroleum, chemical and organic compound industries

Natural gas treatment

Steel creating trade

Power plants

Air acquisition

Compressor coolers

Advantages:

High fin stability, wonderful heat transfer, high operative temperature.

The fin/tube wall contact is constant as a result of the setting and makes it attainable to use a wall temperature of up to 450°C.

The fin is ready throughout its length and consequently doesn’t unwind even once partly uprooted.

This kind of finned tube is one amongst optimum selections for having smart effectiveness/cost magnitude relation.

Weakness:

The fin isn’t therefore sturdy to resist mechanical injury once external forces applied on fin space

Handling shall be through with care to avoid any injury.

Finned tubes is also broken whereas victimisation either steam or aggressive water for cleansing

As the fins square measure helically wrapped in grouves, un-finned space isn\’t lined which may be exposed to corrosive media and galvanic corrosion at the bottom of the fins may be accumulated

Tube shall be straight with disembarrass facet space to create a decent finned tube

It is onerous to use core tube once more once finning is unsuccessful.

Fins ought to be mounted at each ends avoiding un-wrapping

G’ Fin Tüpleri veya Gömülü Fin Tüpleri esas olarak hava kanatlı soğutucularda ve birçok farklı hava soğutmalı radyatör tipinde kullanılır. Bu tip ‘G’ Fin Tüpleri, esas olarak ısı transferi sıcaklığının biraz daha yüksek olduğu alanlarda uygulama bulur. Gömülü Fin Tüpleri esas olarak daha yüksek sıcaklığa sahip yerlerde ve çalışma atmosferinin taban tüpüne nispeten daha az aşındırıcı olduğu yerlerde kullanılır.

Ребристые трубы G’ или встроенные ребристые трубы в основном используются в охладителях с воздушными ребрами и во многих различных типах радиаторов с воздушным охлаждением. Эти типы ребристых труб типа «G» в основном находят применение в областях, где температура теплопередачи находится в несколько более высоком диапазоне. Встроенные ребристые трубы в основном используются в местах с более высокой температурой и там, где рабочая атмосфера относительно менее агрессивна по отношению к основной трубе.

Cangzhou Datang Steel Pipe Co., Ltd located in Cangzhou City,the hometown of pipelines, is a collection of research and development, production, sales in one of the enterprises. The company was founded in 2007 with registered capital 10.08 million RMB, and through the IS09001 international quality system certification, we has high frequency resistance welding finned tube production line 18, extruded finned tube equipment 30, laser welding finned tube production line 2, wound finned tube production line 12. The annual capacity can reach 100,000 tons, the specification φ 18-273mm finned tube, according to the customer requirements of the standard production, service has exceeded 3000+ enterprises.

Our companys tenet is to be Chinas most professional pipeline and equipment suppliers, on the basis of seamless steel tube, integrate the national high quality pipe equipment resources, provide one-stop packaging services,quality makes customer trust, service makes customer relieved, result makes customer comfort, building a conscience, good-hearted, have the sense of responsibility, contributes to the society of the enterprise.Our slogan is professional concentrate in pipeline & accessories 20 years.

Inquiry and consulting support.

Sample testing support.

Visit our factory

After-sales service

Training how to install the tubes, and maintenance.

Engineers available to service overseas.

FAQ

Are you a manufacturer?

We are a professional manufacturer focus on the fin tube area.

Does free shipping is possible?

We don’t offer a free shipping service, but we will offer a discount depends on the quantity.

Do you make OEM?

Yes, we do. We manufacture according to your design and brand standards.

How about the delivery time?

According to the sizes and quantity, delivery time is different. We transport by sea and air normally.

Maintenance

We ensure our standards against erosion and provide professional maintenance advice, for quality advice, we can guarantee for one-year after-sales.