Economizer for industrial boilers in power plants – energy saving_feedwater_environmental protection

- Leave Your Message

Boiler economizer(gas liquid heat exchanger)

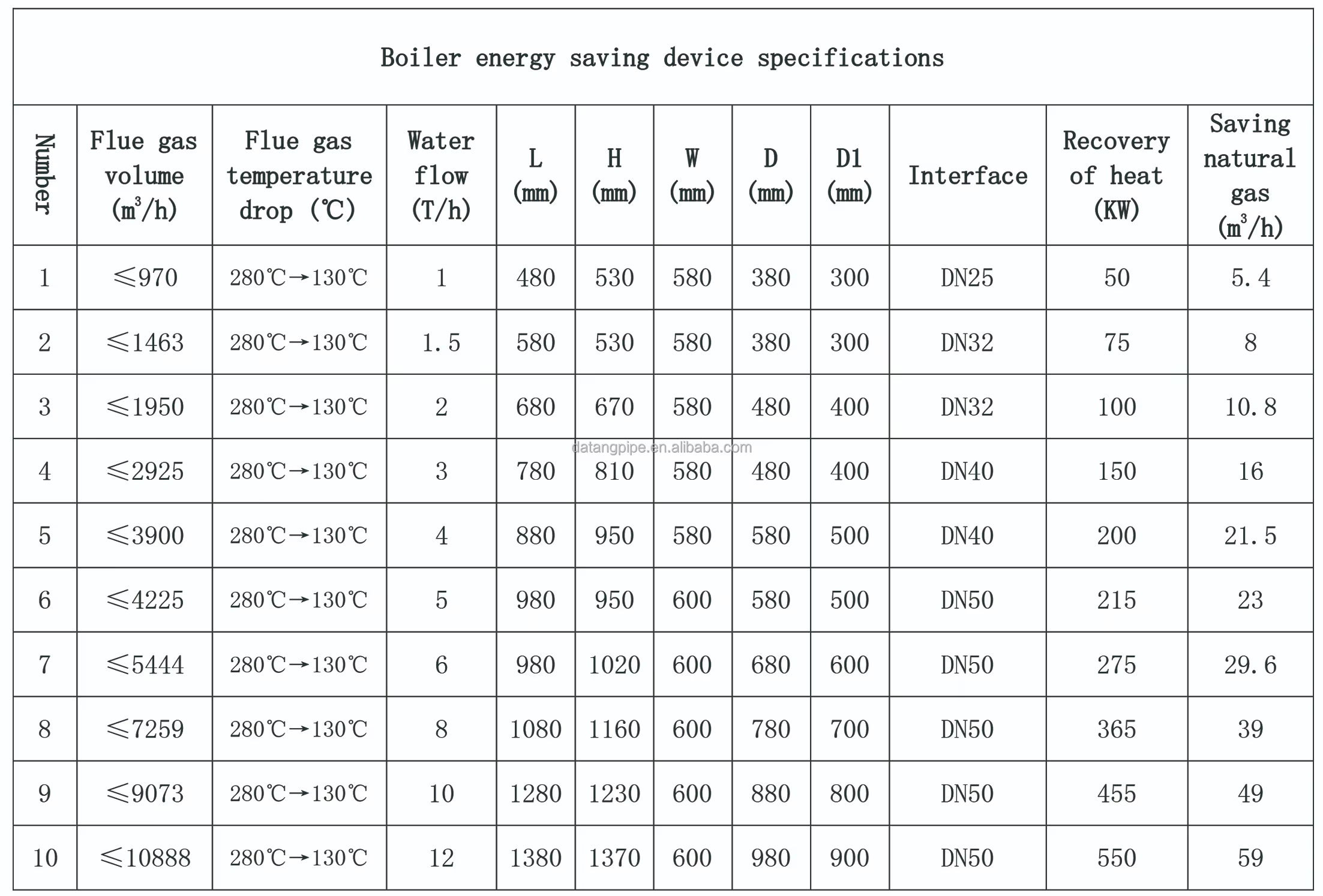

Boiler energy saving device specifications

Boiler economizer(gas liquid heat exchanger)

BOILER ECONOMIZER

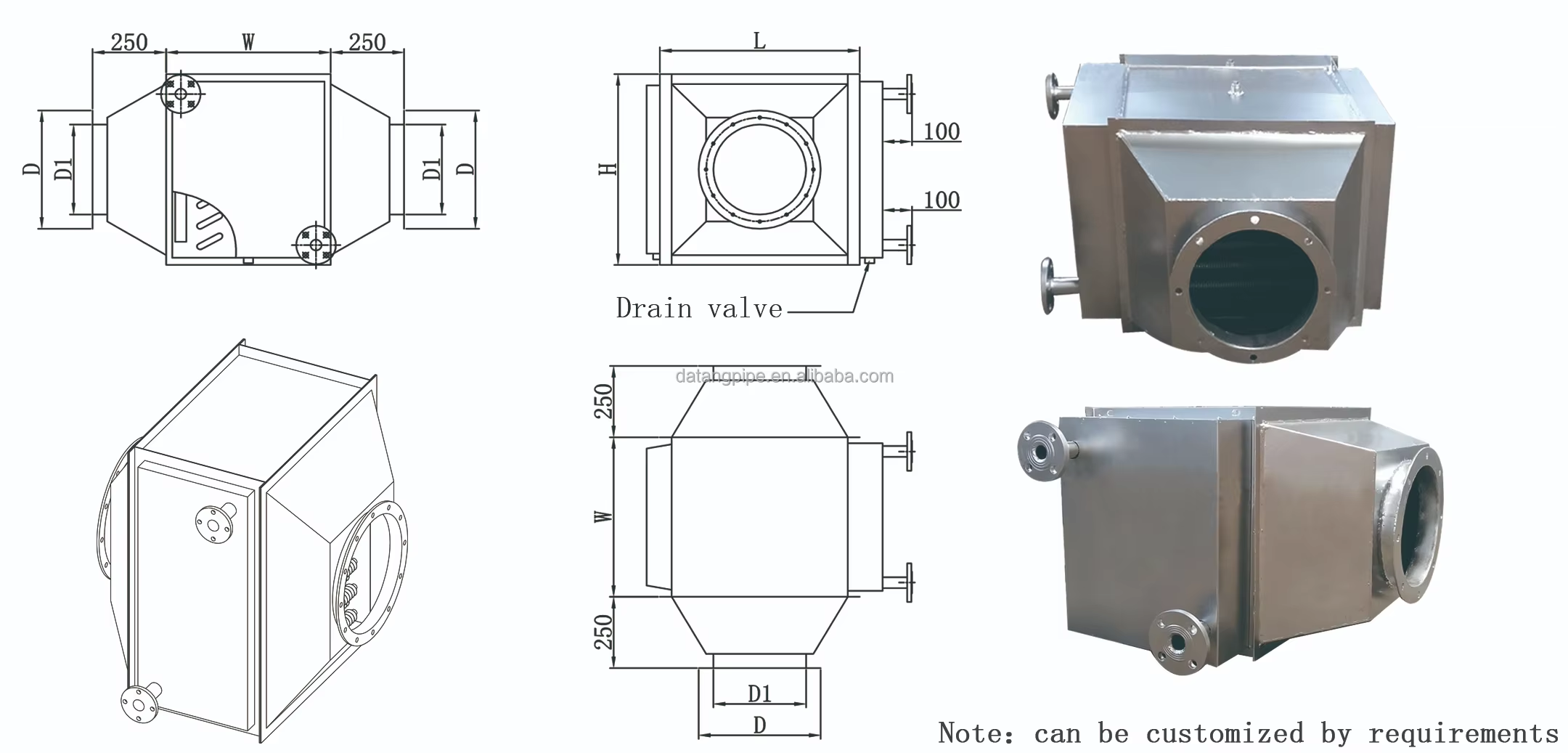

On receipt of your damaged heat recovery unit or drawing we can produce a replica the one to fit into your existing duct work and match up to your existing pipe-work connections when possible. We also offer an on-site boiler economizer measuring service to measure up the existing boiler economizer.

REPLACEMENT BOILER ECONOMIZER

How to customize air heat exchangers ?

1, Provide us completely drawing and we produce according to your drawing.

|

Air heat exchnager ( Steam/heat source to air)

|

|||

|

Heating load

|

KW

|

Flue gas temperature drop

|

℃

|

|

Flue gas flow

|

m3/h

|

Cooling water temperature rise

|

℃

|

|

Cooling flow

|

m3/h

|

||

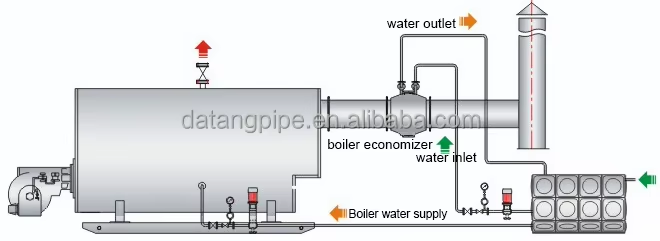

The main function of economizers for industrial boilers in power plants is to absorb the heat of low-temperature flue gas, reduce the exhaust temperature, reduce exhaust losses, and thus save fuel.

The application of economizers in industrial boilers has multiple benefits.

It absorbs the heat of low-temperature flue gas, effectively reduces the exhaust temperature, reduces the heat loss caused by exhaust, and thus achieves fuel savings.

Before the feed water enters the drum, the economizer can preheat the feed water, which reduces the heat absorption of the feed water on the heating surface, so that part of the evaporation heating surface with a higher cost can be replaced by the economizer, thereby reducing costs.

Increasing the feed water temperature can reduce the temperature difference between the inner wall of the drum and the water, reduce thermal stress, and thus extend the service life of the drum.

The application of economizers not only improves the energy efficiency of the boiler, but also enhances the economic and safety of boiler operation.

The economizer is designed and installed at the tail end of the boiler flue, using the waste heat of the boiler flue gas to preheat the feed water. This design makes the use of fuel more efficient and also meets the environmental protection requirements of energy conservation and emission reduction.

In this way, the power plant can further improve energy utilization efficiency and reduce energy consumption, which is of great significance for achieving sustainable development and environmental protection.

Types of heat exchangers produced by Datang

Datang Customer factory inspection-Datang Fin Tube

Our Certificates-Datang Fin Tube

Exhibition Photos -Datang Fin Tube