- Product Name: Extruded Aluminium Fin Heat Exchanger

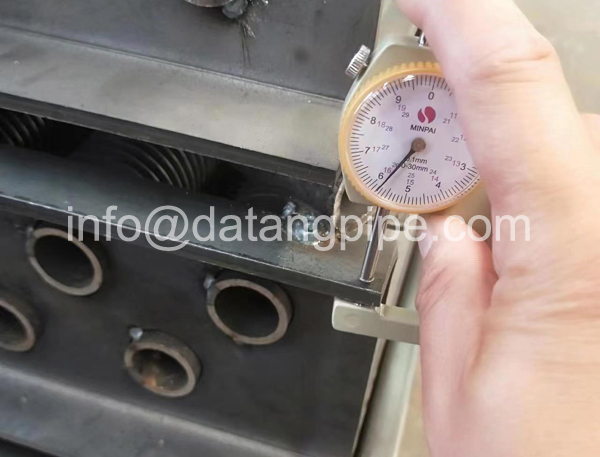

- Fin Tube Type: Extruded Aluminium Fin

- Leave Your Message

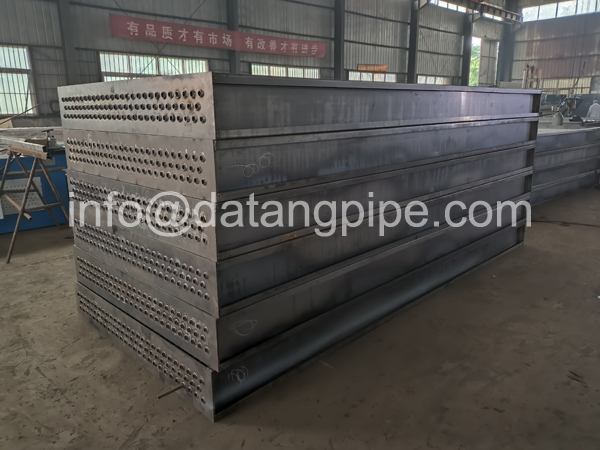

Extruded Aluminium Fin Heat Exchanger is a common heat dissipation equipment, which is mainly composed of aluminum finned tubes. The design purpose of the aluminum finned tube radiator is to improve the heat dissipation efficiency and enhance the heat transfer effect. The finned tube design allows the radiator to have a larger surface area to conduct heat more efficiently. Aluminum material has good heat dissipation performance, so aluminum finned tube radiators are widely used in various fields.

The working principle of the aluminum finned tube heat exchanger is to realize heat dissipation through the heat conduction between the flowing medium and the finned tube. After the heat is exchanged on the surface of the finned tube, it is transferred to the surrounding environment through the convection of the air. The heat exchanger has a compact design and takes up little space, making it suitable for installation in tight spaces. At the same time, the material of the finned tube is aluminum, which has good corrosion resistance and light weight characteristics, and can operate stably for a long time in harsh environments.

Aluminum finned tube heat exchangers are widely used in industry, construction and automotive. In the industrial field, it is often used in the heat dissipation system of cooling equipment and generator sets. In construction, it is used as a radiator in air conditioning systems and HVAC equipment. In short, the aluminum finned tube radiator has become an indispensable and important device in the field of heat transfer due to its high-efficiency heat dissipation performance and wide-ranging adaptability. It plays an important role in various fields, providing high-quality heat dissipation for various devices.

Extruded Aluminium Fin Heat Exchanger is a type of heat exchanger design that uses plates and finned chambers to transfer heat between fluids. It is often categorized as a compact heat exchanger to emphasise its relatively high heat transfer surface area to volume ratio.

Extruded Aluminium Fin Heat Exchanger Advantages :

High heat transfer efficiency especially in gas treatment

Larger heat transfer area

Approximately 5 times lighter in weight than that of shell and tube heat exchanger.

Able to withstand high pressure

Aluminum finned tube heat exchanger Applications :

The cost of Fin heat exchangers is generally higher than conventional heat exchangers due to a higher level of detail required during manufacture. However, these costs can often be outweighed by the cost saving produced by the added heat transfer.

Fin heat exchangers are generally applied in industries where the fluids have little chances of fouling. The delicate design as well as the thin channels in the fin heat exchanger make cleaning difficult or impossible.

It is widely used in heat exchangers, air conditioners, refrigerators, economizers and other thermal industrial components. When theheat or cold source is liquid, such as steam, water, heat transfer oil.

They need heating gas or gas cooling, which requires a larger heat exchange area. Outer fin structure, finned tube area is equivalent to10 times then the normal tube area, can greatly improve the heat transfer area, improve heat transfer performance. This not onlyimproves the efficiency of the device but also greatly reduces the heat transfer cost. Multi-branch parallel structure, in the heatexchange process, flexible design to meet the different conditions of heat flow and temperature difference requirements.