Finned tubes heat Exchanger|Air Cooled Heat Exchanger

What are Air Cooled Heat Exchanger?

Air Cooled Heat Exchangers are a type of heat exchanger that use finned tubes to increase the heat transfer surface area between the two fluids or gases being used to transfer heat. The fins on the tubes increase the heat transfer coefficient and promote turbulence in the fluid flow, allowing for greater heat transfer efficiency.

Finned tube Air Cooled Heat Exchangers are commonly used in applications where one fluid or gas is at a much higher temperature than the other, such as in air conditioning, refrigeration, and power generation. They are also used in industrial processes that involve heating or cooling of liquids or gases, such as in the chemical, petrochemical, and food processing industries.

How to manufacture finned tubes heat exchangers?

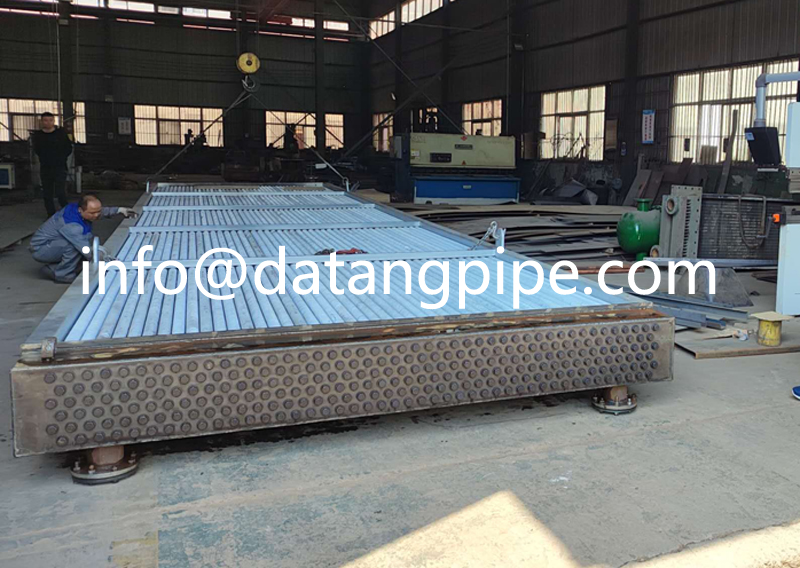

Finned tube heat exchangers consist of a bundle of tubes that are typically made of copper, aluminum, or stainless steel. These tubes are equipped with fins that increase the surface area available for heat transfer. The fins are usually made of the same material as the tubes, but they may also be made of a different material, such as brass or carbon steel.

The construction of finned tube heat exchangers typically involves the following steps:

1. Tube selection – The tubes are selected based on the specific application requirements, such as fluid properties, temperature, pressure, and corrosion resistance.

2. Finning – The tubes are then finned using a finning machine. The finning process involves wrapping a continuous strip of metal around the tube, which is then spirally wound to create the fins.

3. Tube bundling – The finned tubes are bundled together using a tube sheet or header. The tube sheet/header provides a support structure for the tubes and ensures proper alignment.

4. Assembly – The tube bundle is assembled into a shell or casing, which contains the fluid or gas being heated or cooled. The shell may have baffles or other flow control devices to promote efficient heat transfer.

5. Insulation – The heat exchanger may be insulated to reduce heat loss or to prevent condensation.

6. Accessories – The heat exchanger may be equipped with various accessories, such as temperature sensors, pressure gauges, and valves, depending on the specific application requirements.

The design and construction of finned tube heat exchangers may vary depending on the specific application requirements, and various factors such as tube material, fin design, and assembly method may be optimized to achieve the desired heat transfer efficiency and performance.

Finned tubes heat exchangers manufacture standard

The manufacture standards for finned tube heat exchangers can vary depending on the specific application and industry. Some common manufacturing standards used for finned tube heat exchangers include:

1. ASME Boiler and Pressure Vessel Code – This is a set of standards developed by the American Society of Mechanical Engineers (ASME) for the design, construction, and inspection of pressure vessels and boilers.

2. EN 13445 – This is a European standard for the design and manufacture of pressure vessels and heat exchangers.

3. API 660 – This is a standard developed by the American Petroleum Institute (API) for the design and manufacture of shell-and-tube heat exchangers for the petroleum, petrochemical, and natural gas industries.

Hydrostatic test

4. TEMA – This is a set of standards developed by the Tubular Exchanger Manufacturers Association (TEMA) for the design and manufacture of shell-and-tube heat exchangers.

5. ISO 9001 – This is a set of quality management standards developed by the International Organization for Standardization (ISO) that apply to the design, development, production, installation, and servicing of products.

6. ASTM – This is a set of standards developed by the American Society for Testing and Materials (ASTM) that cover a wide range of materials, products, and services.

Manufacturing standards are important for ensuring the quality, safety, and reliability of finned tube heat exchangers. By following these standards, manufacturers can ensure that their products meet the necessary requirements for their intended application and can provide consistent performance over time.