Project Description

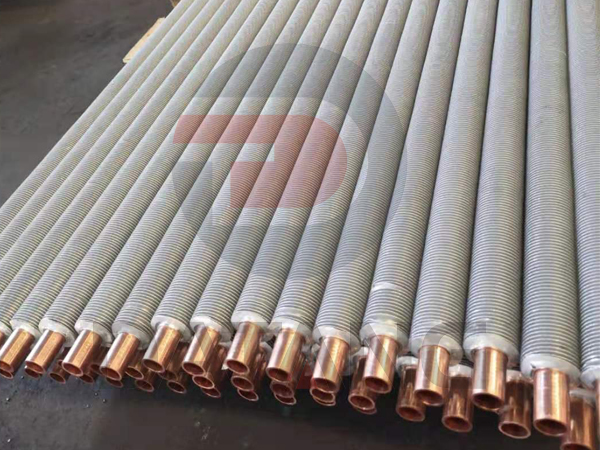

Copper,Aluminum,Titanium Extruded Finned Tube

- Fin Type: Extruded Fin Tube.

- Tube Material: Copper, copper nickel, stainless steel, titanium, etc.

- Fin Material: Copper, aluminum

- Product description:

Extruded Fin Tube Supplier: Copper, Aluminum, Titanium Fin Tube, OD 21.3-73 MM, WT 2-7.62 MM, Fin Thickness 0.8-2.5 MM, Fin Pitch 4-35 MM, Fin Width 10-25 MM.

- Leave Your Message

Fin Type: Extruded Fin Tube.

Tube Material: Copper, copper nickel, stainless steel, titanium, etc.

Fin Material: Copper, aluminum.

Tube OD: 21.3mm-73mm.

Tube Thickness: 2mm-7.62mm.

Fin Thickness: 0.8-2.5mm.

Fin Pitch: 4-35mm.

Fin Width: 10-25mm.

Product description:

Aluminum extruded finned tubes using the form of the base tube covered with aluminum tube(the base tube can be carbon steel, stainless steel, copper) through machine extrusion, forming a tube fin, the fin base and the tube outer wall is close fitting, this fin tubing control can make finned tubes with high heat transfer coefficient and heat transfer performance.

What is extruded finned tube?

Aluminum extruded finned tubes, also called “integral finned tubes” using the form of the base tube covered with aluminum tube(the base tube can be carbon steel, stainless steel, copper) through machine extrusion, forming a tube fin, the fin base and the tube outer wall is close fitting, this fin tubing control can make finned tubes with high heat transfer coefficient and heat transfer performance. Extruded finned tube can be made of iron, copper or aluminum tube by compound rolling, which has the advantages of tight bonding, small thermal resistance, good heat transfer performance, high strength, small flow loss, strong anti-corrosion performance, not easy to deformation under long-term hot and cold working conditions, long working life and so on.

Extruded finned tube manufacturing process

Pipe line——compressing or rolling——strip peeling——washing——pressure test——blast blowing——packaging.

The extruded fin tube is formed by a bimetallic tube consisting of an aluminum outer tube and an inner tube of almost any material. The fin is formed by rolling the material from the outside of the outer tube to provide an integrated fin with excellent heat transfer performance and life. The extruded fins provide excellent corrosion protection for the base tube.

The production method of the composite finned tube mainly includes the extrusion method: the bimetallic composite tube is lined with a mandrel, and driven by the rotation of the roller blade, the composite tube is processed on the outer surface through the cavity formed by the rolling groove and the core head Out fins. The heat transfer tube produced by this method is an organic whole with its outer tube and fins, so there is no problem of contact heat loss, and it has good performance and high heat transfer efficiency.

Extruded finned tube advantages

Compared with the ordinary wound finned tube, the contact thermal resistance remains stable in a large range with the temperature change, so the heat transfer performance of the bimetallic aluminum extruded finned tube is better than the spiral fin tube in the limit tube wall temperature range.

In addition, compared with the coiled tube, the bimetallic aluminum extruded fin tube has outstanding corrosion resistance and high strength, it can withstand 4.0MPa water pressure cleaning, the fins still do not fall down, the base of the bimetallic aluminum extruded tube. The tube can be selected according to the corrosion of the fluid in the tube and the processing technology. The base tube can be carbon steel, copper, stainless steel, etc.

Extruded finned tube applications

Extruded finned tubes are the main equipment for air coolers and are commonly used as heat exchangers in power plants (electric, nuclear, thermal and geothermal). Steam condensate system. Chemical and petrochemical industries. Food processing plants and refrigeration technology. Industry (steel mills, incinerators, gas compression facilities). Petrochemical, power plant and power plant renovation, air conditioning and refrigeration, boilers, finned tube economizers and air preheaters. Maximum working temperature is 280°C-300°C.

Technical Specifications for Bimetal Extruded Finned Tubes:

| Tube Code | d | D | P | Fins per Inch |

Surface Area |

| mm | mm | mm | Nos. | Sq.m/m | |

| BM-16-37-2.8 | 16 | 37±1 | 2.80 | 9 | 0.62 |

| BM-16-37-2.5 | 2.54 | 10 | 0.69 | ||

| BM-16-37-2.3 | 2.30 | 11 | 0.76 | ||

| BM-19.05-42-2.8 | 19.05 | 42±1 | 2.80 | 9 | 0.78 |

| BM-19.05-42-2.5 | 2.54 | 10 | 0.86 | ||

| BM-19.05-42-2.3 | 2.30 | 11 | 0.95 | ||

| BM-22.22-54-3.6 | 22.22 | 54±1 | 3.62 | 7 | 1.05 |

| BM-22.22-54-3.1 | 3.17 | 8 | 1.19 | ||

| BM-22.22-54-2.8 | 2.80 | 9 | 1.35 | ||

| BM-22.22-54-2.5 | 2.54 | 10 | 1.50 | ||

| BM-22.22-54-2.3 | 2.30 | 11 | 1.65 | ||

| BM-25.4-57.15-3.6 | 25.4 | 57.15 (+0.8,-1.2) |

3.62 | 7 | 1.13 |

| BM-25.4-57.15-3.1 | 3.17 | 8 | 1.29 | ||

| BM-25.4-57.15-2.8 | 2.80 | 9 | 1.46 | ||

| BM-25.4-57.15-2.5 | 2.54 | 10 | 1.62 | ||

| BM-25.4-57.15-2.3 | 2.30 | 11 | 1.78 | ||

| BM-31.75-63.5-3.6 | 31.75 | 63.5 (+0.8,-1.2) |

3.62 | 7 | 1.30 |

| BM-31.75-63.5-3.1 | 3.17 | 8 | 1.49 | ||

| BM-31.75-63.5-2.8 | 2.80 | 9 | 1.68 | ||

| BM-31.75-63.5-2.5 | 2.54 | 10 | 1.86 | ||

| BM-31.75-63.5-2.3 | 2.30 | 11 | 2.05 | ||

| BM-38.1-69.85-3.6 | 38.1 | 69.85 (+0.8,-1.2) |

3.62 | 7 | 1.48 |

| BM-38.1-69.85-3.1 | 3.17 | 8 | 1.69 | ||

| BM-38.1-69.85-2.8 | 2.80 | 9 | 1.91 | ||

| BM-38.1-69.85-2.5 | 2.54 | 10 | 2.12 | ||

| BM-38.1-69.85-2.3 | 2.30 | 11 | 2.33 | ||

| BM : Bimetalic Extruded Finned Tubes | |||||

| d : Base tube diameter | |||||

| D : Fin Outer diameter | |||||

| P : Fin pitch | |||||

Technical Specifications for Monometalic Extruded Finned Tubes:

| Tube Code | D | d | dw | P | Fins per Inch |

| mm | mm | mm | mm | Nos. | |

| MM-38-20-16-2.8 | 38 | 20 | 16 | 2.80 | 9 |

| MM-38-20-16-2.5 | 2.54 | 10 | |||

| MM-38-20-16-2.3 | 2.30 | 11 | |||

| MM-51-29-25-3.6 | 51 | 29 | 25 | 3.62 | 7 |

| MM-51-29-25-3.1 | 3.17 | 8 | |||

| MM-51-29-25-2.8 | 2.80 | 9 | |||

| MM-51-29-25-2.5 | 2.54 | 10 | |||

| MM-51-29-25-2.3 | 2.30 | 11 | |||

| MM-57-33-29-3.6 | 57 | 33 | 29 | 3.62 | 7 |

| MM-57-33-29-3.1 | 3.17 | 8 | |||

| MM-57-33-29-2.8 | 2.80 | 9 | |||

| MM-57-33-29-2.5 | 2.54 | 10 | |||

| MM-57-33-29-2.3 | 2.30 | 11 | |||

| MM : Monometalic Extruded Finned Tubes | |||||

| D : Fin outer diameter | |||||

| d : Root diameter | |||||

| dw : Tube ID | |||||

| P : Fin pitch | |||||

Cangzhou Datang Steel Pipe Co., Ltd located in Cangzhou City,the hometown of pipelines, is a collection of research and development, production, sales in one of the enterprises. The company was founded in 2007 with registered capital 10.08 million RMB, and through the IS09001 international quality system certification, we has high frequency resistance welding finned tube production line 18, extruded finned tube equipment 30, laser welding finned tube production line 2, wound finned tube production line 12. The annual capacity can reach 100,000 tons, the specification φ 18-273mm finned tube, according to the customer requirements of the standard production, service has exceeded 3000+ enterprises.

Our companys tenet is to be Chinas most professional pipeline and equipment suppliers, on the basis of seamless steel tube, integrate the national high quality pipe equipment resources, provide one-stop packaging services,quality makes customer trust, service makes customer relieved, result makes customer comfort, building a conscience, good-hearted, have the sense of responsibility, contributes to the society of the enterprise.Our slogan is professional concentrate in pipeline & accessories 20 years.

Inquiry and consulting support.

Sample testing support.

Visit our factory

After-sales service

Training how to install the tubes, and maintenance.

Engineers available to service overseas.

FAQ

Are you a manufacturer?

We are a professional manufacturer focus on the fin tube area.

Does free shipping is possible?

We don’t offer a free shipping service, but we will offer a discount depends on the quantity.

Do you make OEM?

Yes, we do. We manufacture according to your design and brand standards.

How about the delivery time?

According to the sizes and quantity, delivery time is different. We transport by sea and air normally.

Maintenance

We ensure our standards against erosion and provide professional maintenance advice, for quality advice, we can guarantee for one-year after-sales.