Project Description

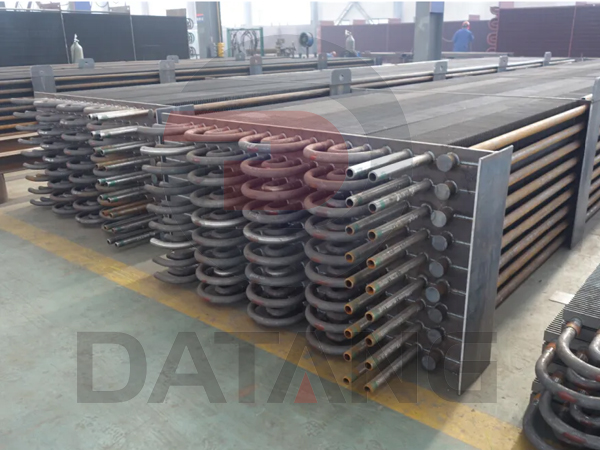

H fin tube is a kind of boiler parts, to have two steel circular symmetry to be welded on fluorescent tubes to form fins positive shap much like letter “H”, so called H-fin tube. H-economizer widely used in utility boilers, industrial boilers, marine power, such as the tail of heat exchanger components.

Steel H Pairs of parallel shaped steel fins are resistance welded to the single pressure tubes (pipes) surface under very carefully controlled conditions.The purpose build welding machine ensures very precise indexing along the entire length of the tubes (pipes) and exact parallel attachment.

Double H h, double H / double H fin tubes

A development of the single tubes (pipes) version, the ‘Double H’ design has the steel fins welded onto two tubes at the same time. For applications with cleaner gases the use of ‘Double H’ can reduce the number of supports required due to its inherent stiffness.

H /HH fin tubes

Application:It is widely used for Heat exchanger, Air-conditioner, Refrigerator, Economizer

And other parts of Heat Industry.

Material of base pipeCarbon steel, Alloy steel, Aluminium or Stainless

Material of finsCarbon steel, Alloy steel or Stainless

Type of base pipeSeamlesss, Welded

Type of finsH, HH

OD of Base pipes15mm-219mm

WT of base pipes1.5-6mm

Height of fins8mm-30mm

WT of fins0.5mm-3.0mm

Pitch of fins2.0mm-20mm

Length of blank areaaccording to Customer’s request.

Length of finned tubes≤ 23m

H/HH fin tubes.

Configurations

As a general guide, spacing of tubes (pipes) centres is usually in the range of 2-3 times the tubes (pipes) O/Dia.

. tubes (pipes) O/Dia. [OD] mm – 31.8 to 57.2

. tubes (pipes) Length [L] Metres – Up to and including 18 Metres maximum

. Vertical Centres [V] mm – 65 to 133

. Horizontal Centres [H] mm – 65 to 178

. Fin Thickness [t] mm – 2.0, 2.5, 3.0 (certain fin shapes can be 1.5mm thick material)

. Fin Density [P] mm – Minimum 10mm, i.e. 100 Fins Per Metre (FPM)

. Fin Shape – Over 75 fin shapes as standard, with new fin shapes continually being developed.

Bespoke fin shapes are produced to suit the design application where feasible.

Base tubes (pipes) Material

Typically Carbon, Corten, Low alloy steels.

Tubes quality / type can be Cold Drawn Seamless [CDS], Hot Finished Seamless [HFS], Electric Resistance Welded [ERW].

Fin Material

Carbon Steel Hot Rolled [HR4], Corrosion resisting steels i.e. Corten.

Manufacturing Process

Square or Rectangular fins are welded on one or two steel base tubes. We call it H and HH or Doule H Fin Type Tubing.

Applications

1. Economizers;

2. Heat exchangers;

3. Marine boilers.

Base tube diameter 25mm-73mm

Base tube wall thickness 3.0mm-6.0mm

Fin thickness 1.5mm-4.0mm

Fin pitch 9.0mm-30.0mm

Fin height 15.0mm-45.0mm

Base tube material: Stainless steel, Carbon steel, Alloy, Nickel etc.

Fin material: Carbon steel, Stainless steel, Alloy etc.

Cangzhou Datang Steel Pipe Co., Ltd located in Cangzhou City,the hometown of pipelines, is a collection of research and development, production, sales in one of the enterprises. The company was founded in 2007 with registered capital 10.08 million RMB, and through the IS09001 international quality system certification, we has high frequency resistance welding finned tube production line 18, extruded finned tube equipment 30, laser welding finned tube production line 2, wound finned tube production line 12. The annual capacity can reach 100,000 tons, the specification φ 18-273mm finned tube, according to the customer requirements of the standard production, service has exceeded 3000+ enterprises.

Our companys tenet is to be Chinas most professional pipeline and equipment suppliers, on the basis of seamless steel tube, integrate the national high quality pipe equipment resources, provide one-stop packaging services,quality makes customer trust, service makes customer relieved, result makes customer comfort, building a conscience, good-hearted, have the sense of responsibility, contributes to the society of the enterprise.Our slogan is professional concentrate in pipeline & accessories 20 years.

Inquiry and consulting support.

Sample testing support.

Visit our factory

After-sales service

Training how to install the tubes, and maintenance.

Engineers available to service overseas.

FAQ

Are you a manufacturer?

We are a professional manufacturer focus on the fin tube area.

Does free shipping is possible?

We don’t offer a free shipping service, but we will offer a discount depends on the quantity.

Do you make OEM?

Yes, we do. We manufacture according to your design and brand standards.

How about the delivery time?

According to the sizes and quantity, delivery time is different. We transport by sea and air normally.

Maintenance

We ensure our standards against erosion and provide professional maintenance advice, for quality advice, we can guarantee for one-year after-sales.