Project Description

Product Description

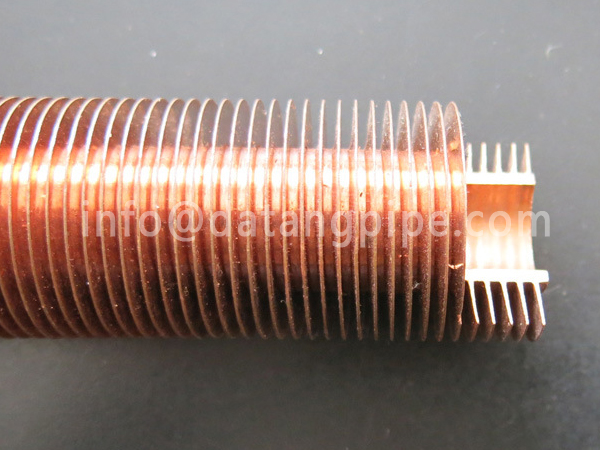

High Finned Tube:

| High Fin Tube | Tube | Tube Material | Fin | Fin Material | |

| L-Fin Tube ( Wrap On Type ) |

12.70-50.8mm OD | All kind of material can be applied. | 7-11.5 Fin / Inch | Copper | |

| G-Fin Tube (Imbeded Type) | 12.70-50.8mm OD | All kind of material can be applied. | Fin Height Max 16mmH | C 1100, C 1220 Aluminium A 1100, A 1050, A 1060 |

|

| High Frequency Welded Fin Tube | 12.70-160mm OD | Carbon Steel Tube Stainless Steel Tube included alloy material |

1.5-7 Fin / Inch 0.8-3.2mm. Thickness |

Carbon Steel Tube Stainless Steel Tube included alloy material |

|

| Intergral Copper & Copper Alloy High Fin Tube | 15.88-22.23mm ID | C1220, C1100, C7060 | 5-15 Fin / Inch Max 12mm. H |

||

| Oval Fin Tube | All Size Available | Carbon Steel Tube Stainless Steel Tube included alloy material Copper & Copper Alloy Tube |

5-15 Fin / Inch | Carbon Steel Tube Stainless Steel Tube included alloy material Copper & Copper Alloy Tube |

High Finned Tubes have extruded fin heights up to 0.625″ (16mm). Single metal and bi-metallic finned tubes are available. Bi-metal finned tubes have a separate alloy liner tube inside the extruded fins. The mono-metal finned tubes have no liner tube with the fins integral with the tube.

High Finned Tube is made from extruded fins with a different alloy liner tube. The High Fins are up to 0.625″ (16mm) high. Extruded fin tubes are formed helically out of a aluminum alloy tube. The result is an integrally formed finned tube with an excellent fin-to-tube uniformity providing exceptional efficiency and longevity. Whether rough service, high temperatures, or corrosive environment, extruded fin tubes are a great option for heat exchanger applications. This type of product is excellent for warm air heating, air coolers, machinery coolers, power station coolers, and tower coolers.

| Fins Per Inch: | 5-11 FPI |

|---|---|

| Fin Height: | 0.63″ max |

| Root Diameter: | 0.63″ to 1.5″ OD |

| Fin Material: | Al |

| Liner Tube Material: | Cu, CuNi, Br, SS, CS, Ni, Ti |

| *Max Process Temperature: | 570 °F |

High Finned Tube is made from mono extruded copper alloys. The High Fins are up to 0.400″ (10mm) high. Extruded fin tubes are formed helically out of a mono-metal tube. The result is an integrally formed finned tube with an excellent fin-to-tube uniformity providing exceptional efficiency and longevity. Whether rough service, high temperatures, or corrosive environment, extruded fin tubes are a great option for heat exchanger applications. High Finned Tubes can be annealed to a soft state for bending and coiling. This type of product is excellent for heating, refrigeration, machinery coolers, water-heaters, and boilers.

| Fins Per Inch: | 7,8,9 |

|---|---|

| Fin Height: | 0.400″ max |

| Root Diameter: | 0.75″ to 1.25″ OD |

| Tube Material: | Cu, CuNi, Al |

| Max Process Temperature: | Thermal Properties of Tube |

Cangzhou Datang Steel Pipe Co., Ltd located in Cangzhou City,the hometown of pipelines, is a collection of research and development, production, sales in one of the enterprises. The company was founded in 2007 with registered capital 10.08 million RMB, and through the IS09001 international quality system certification, we has high frequency resistance welding finned tube production line 18, extruded finned tube equipment 30, laser welding finned tube production line 2, wound finned tube production line 12. The annual capacity can reach 100,000 tons, the specification φ 18-273mm finned tube, according to the customer requirements of the standard production, service has exceeded 3000+ enterprises.

Our companys tenet is to be Chinas most professional pipeline and equipment suppliers, on the basis of seamless steel tube, integrate the national high quality pipe equipment resources, provide one-stop packaging services,quality makes customer trust, service makes customer relieved, result makes customer comfort, building a conscience, good-hearted, have the sense of responsibility, contributes to the society of the enterprise.Our slogan is professional concentrate in pipeline & accessories 20 years.

Inquiry and consulting support.

Sample testing support.

Visit our factory

After-sales service

Training how to install the tubes, and maintenance.

Engineers available to service overseas.

FAQ

Are you a manufacturer?

We are a professional manufacturer focus on the fin tube area.

Does free shipping is possible?

We don’t offer a free shipping service, but we will offer a discount depends on the quantity.

Do you make OEM?

Yes, we do. We manufacture according to your design and brand standards.

How about the delivery time?

According to the sizes and quantity, delivery time is different. We transport by sea and air normally.

Maintenance

We ensure our standards against erosion and provide professional maintenance advice, for quality advice, we can guarantee for one-year after-sales.