Project Description

Welded Helical Condenser Extruded Finned Tube

- Leave Your Message

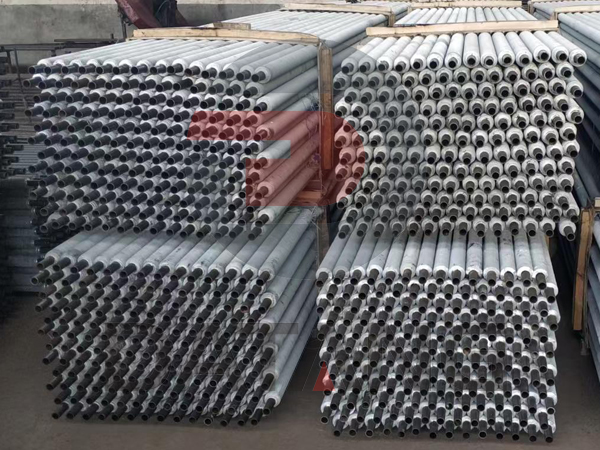

Welded Helical Condenser Extruded Fin Tube

Cangzhou Datang Steel Pipe as one of the leading suppliers in China to supply Welded Helical Condenser Extruded Fin Tube for petroleum industry and Heat Exchanger industry etc.

Cangzhou Datang Steel Pipe offers the widest variety of sizes available in the industry. All of our products are domestically sourced, developed, and produced, which means our customers have immediate access to exactly the products they need for their particular application. And you are assured of the highest quality and manufacturing standards and a local, concerned, customer service presence.

Welded Helical Condenser Extruded Finned Tube

The processing technology of steel-aluminum Extruded Type Finned Tube is to first process aluminum tube and steel tube into

bimetallic composite tube, and then form fins after mechanical cold rolling. The aluminum fins are tightly combined into a

bimetallic tube finned tube (composite extruded finned tube)

Welded Helical Condenser Extruded Fin Tube are integrally rolled from aluminum tubes, and have the characteristics of no contact thermal

resistance, high strength, thermal shock resistance and mechanical shock resistance, good thermal performance, and a considerable

expansion heat transfer surface. This finned tube heat exchanger is in front of the tube or around the plate.

Welded Helical Condenser Extruded Fin Tube Quick Details:

Core tube material:

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L/316Ti, A789 S31803/S2205

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

Fin material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

Fin type: Solid plain

Fin Tube Type: G Type Embedded

Outer diameter (OD): 16mm Min~50.8mm max.

Tube length: up to 18,000 mm.

Fin height: 16.5mm max.

Fin thickness: generally 0.4mm~0.6mm

Fin pitch: 2.1mm minimum (12FPI)

Surface Protection: Both bare ends shall be zinc or aluminum metallized by electrospray arc system coating.

Accessories: Tube support boxes, clamps or spacer boxes (materials: aluminium, zinc and stainless steel).

The strong connection between fin and base tube prevents loosening of fin because of heat stress, oxidization, corrosion etc., use at very high temperatures possible. This welded steel finned tubes configuration can be used in practically any heat transfer applications, and particularly suited for high temperature, high pressure applications. The important features of this configuration are efficient, effective bond of fin to tube under any conditions of temperature and pressure, and ability to withstand high fin-side temperatures.

These tubes are used with a wide range of material such as carbon steel, low alloys steel and stainless steel for corrosive flue gas or high temperatures. The finned tube can supply these tubes shaped in hairpin, with extremities bevelled.

Application Heat Transfer Equipment including Heat Exchangers, Boilers, Economizers, Super Heaters, Fired Heaters, HRSG, Waste Heat Recovery Systems etc.

Services In addition to finning and tube bending we offer tubing, pipe, cutting, beveling, return bends, elbows, crating, freight and economizer consulting.

In general, the fin configuration is said to transfer heat more efficiently than solid fin since the serrated fin segments allow some lateral (cross-fin) flow of fluid along the tube axis, which serves to increase turbulence, thereby breaking up the thermal boundary layer and increasing heat transfer efficiency.