High Finned Tubes For Efficient Heat Transfer

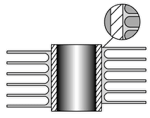

High-fin tubes are heat transfer components that feature closely spaced fins extruded or integrally bonded onto the base tube. They offer increased surface area, improved heat transfer efficiency, and find extensive use in various industries requiring efficient heat exchange.

High finned tubes basically consist of a metal tube, surrounded by an aluminum strip or sometimes copper strip. This strip can be applied in different ways. A distinction is made, among others, between a type L, a type KL, a type LL, a type G (= embedded) or a type extruded. With extruded finning the fins are produced our of an aluminium tube instead of aluminium strip. The metal tube can be made of different types of metal, depending on the intended application of the high finned tubes. Within a heat exchanger, the hot medium runs through the finned tubes and heats the tube and the aluminium fins. The metal tube heats up, after which it transfers its heat to the aluminum fins. These fins then ensure that the heat is transferred into the ambient air.

Pure Copper Finned Tube

High Finned Tube Pure Copper Finned Tube-Copper Extruded Finned Tube

HIGH FINNED TUBES

High Finned Tubes have extruded fin heights up to 0.625″ (16mm). Single metal and bi-metallic finned tubes are available. Bi-metal finned tubes have a separate alloy liner tube inside the extruded fins. The mono-metal finned tubes have no liner tube with the fins integral with the tube.

High finned tubes are the most critical components of air-cooled heat exchangers, which is why they must be of the highest quality and fully meet customer specifications.

EMBEDDED FINNED TUBES: G-FIN TECHNOLOGY

The grooved fin is mechanically bonded into the tube wall, guaranteeing optimal heat transfer and bonding capabilities up to 400°C.

During production, a groove is precisely machined into the tube wall with a depth of 0.25 (+/- 0.05) mm. Subsequently, the aluminium strip is carefully rolled into the groove, and the groove is sealed using so called backfillers. This process effectively locks the strip in the tube wall, ensuring complete contact with the base tube, even at elevated temperatures. The result is a robust and efficient heat transfer mechanism provided by the G-FIN technology.

EMBEDDED FINNED TUBES: G-FIN TECHNOLOGY

The grooved fin is mechanically bonded into the tube wall, guaranteeing optimal heat transfer and bonding capabilities up to 400°C.

During production, a groove is precisely machined into the tube wall with a depth of 0.25 (+/- 0.05) mm. Subsequently, the aluminium strip is carefully rolled into the groove, and the groove is sealed using so called backfillers. This process effectively locks the strip in the tube wall, ensuring complete contact with the base tube, even at elevated temperatures. The result is a robust and efficient heat transfer mechanism provided by the G-FIN technology.

With over 20 years of experience, Datang Fin Tube specializes in producing all types of finned tubes, including:

We guarantee top-tier quality by:

Using raw materials from trusted European suppliers

Performing rigorous quality checks at every stage of production

Ensuring every tube meets strict industry standards before shipping

Whether for air-cooled heat exchangers or other applications, our finned tubes deliver unmatched performance and reliability.

What are high fin tubes?

High-fin tubes, also known as integral finned tubes or extruded finned tubes, are specialized heat transfer components designed to enhance heat exchange efficiency. They feature a series of fins that are tightly integrated or extruded onto the outer surface of a base tube.

High Finned Tubes Function

The primary purpose of high-fin tubes is to increase the surface area available for heat transfer. By incorporating fins onto the tube, the effective surface area is significantly expanded, allowing for improved heat transfer between the fluid inside the tube and the surrounding medium.

The fins on high-fin tubes can vary in size, shape, and configuration, depending on the specific application requirements. They are typically taller and more closely spaced compared to regular fins, maximizing the surface area and promoting efficient heat exchange.

High Finned Tubes Process

The manufacturing process of high-fin tubes involves extruding or integrally bonding the fins onto the base tube. This ensures a strong mechanical bond and enables efficient heat transfer by eliminating any air gaps or thermal barriers between the fins and the tube.

High-fin tubes are commonly made from materials such as copper, aluminum, or stainless steel, depending on the specific application and its requirements for corrosion resistance, thermal conductivity, and mechanical strength.

These tubes find wide application in heat exchangers, air coolers, condensers, and other heat transfer systems. They are particularly useful in industries such as HVAC, refrigeration, power generation, and process industries where efficient heat transfer is crucial.

The advantages of high-fin tubes:

1. Enhanced Heat Transfer: The increased surface area provided by the fins improves heat exchange efficiency, allowing for more effective cooling or heating.

2. Compact Design: High-fin tubes offer a higher surface area-to-volume ratio, enabling the construction of more compact and efficient heat exchangers.

3. Improved Performance: The extended surface area of the fins allows for higher heat transfer rates and better overall system performance.

4. Reduced Fouling: The closely spaced fins on high-fin tubes help minimize fouling by preventing the accumulation of debris or deposits on the tube surface.

5. Customization: The design and dimensions of the fins can be tailored to meet specific heat transfer requirements, allowing for optimal performance in various applications.

Helical High Fins

Helical high finned tubes are used to repair air-cooled heat exchangers and are available in 5 variations

| Type | Photo | Descriptions | Properties |

|---|---|---|---|

| “KL” fin tubes |  |

After application the fin foot is knurled into the corresponding knurling on the base tube thereby enhancing the bond between the fin and tube resulting in improved heat transfer characteristics. Max. operating. temp. 260ºC | Max working temperature – 260 °C (500 °F) Atmospheric corrosion resistance – acceptable Mechanical resistance – acceptable Fin material – aluminum, copper |

| “G” fin tubes |  |

Fin strip is wound & embedded on a groove and securely locked by closing the groove with the base tube metal. This ensures maximum heat transfer at high temperatures. Max. operating temp. 450ºC |

Max working temperature – 400 °C (752 °F) Atmospheric corrosion resistance – poor Mechanical resistance – acceptable Fin material – aluminum, copper, carbon steel |

| “LL” fin tubes |  |

Manufactured in the same way as the ‘L’ fin type except that the fin foot is overlapped to completely enclose the base tube thereby giving excellent corrosion resistance. This type of tube is often used as an alternative to the more expensive extruded type fin in corrosive environments. Max. operating. temp. 180ºC | Max working temperature – 180 °C (356 °F) Atmospheric corrosion resistance – acceptable Mechanical resistance – poor Fin material – aluminum, copper |

| “L” fin tubes |  |

The strip material is subjected to controlled deformation under tension giving the optimum contact pressure of the foot of the fin onto the base tube thus maximizing the heat transfer properties. The foot of the fin considerably enhances the corrosion protection of the base tube. Max. operating. temp. 150ºC | Max working temperature – 150 °C (302 °F) Atmospheric corrosion resistance – acceptable Mechanical resistance – poor Fin material – aluminum, copper |

| Extruded fin tubes |  |

This fin type is formed from a bi-metallic tube consisting of an aluminium outer tube and an inner tube of almost any material. The fin is formed by rolling material from the outside of the exterior tube to give an integral fin with excellent heat transfer properties and longevity. Extruded fin offers excellent corrosion protection of the base tube. Max. operating. temp. 280ºC. | Max working temperature – 285 °C (545 °F) Atmospheric corrosion resistance – excellent Mechanical resistance – excellent Fin material – aluminum |

Delivery & Inspection

The first actual inspection work on the fin tube heat exchanger is the raw materials inspection. Based on the ASME Code, providing material test reports for fin tube heat exchanger plates is mandatory. For other components, the marking inspection will be enough.