Project Description

Product Name: Embedded Fin Tube for Air Cooler Heat Exchanger

- Leave Your Message

EMBEDDED FIN

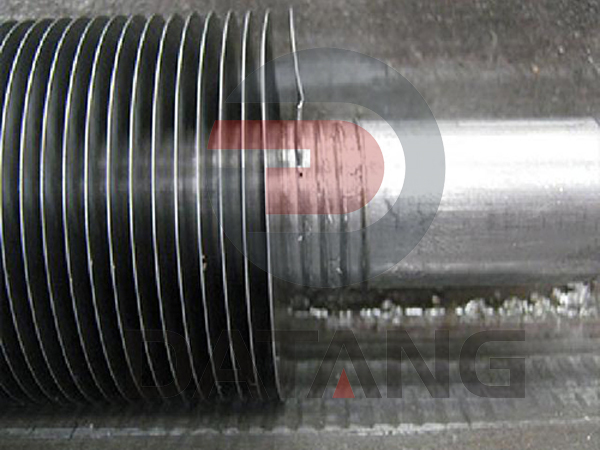

Embedded Fin tube “G Type” is made with the fin strip wounded into a machined groove and securely locked into place by back filling with base tube material. This technique ensures maximum heat transfer and a temperature of working until 450C°.

For this type of finned tubes our productive capacity is over 2000 meters per day.

G FIN

The fin strip is wound into a machined groove and securely locked into place by back filling with base tube material. This ensures that maximum heat transfer is maintained at high tube metal temperatures.

Embedded Fin Tube for Air Cooler Heat Exchanger

Embedded fin tube consists of aluminum fin strip that is mechanically embedded into the wall of the tube. The embedding process is controlled by tooling that first plows a groove into the tubes outside diameter, then guides the base of the fin into the groove and finally locks the fin in place by rolling the groove closed on the base of the fin. This strong mechanical bond holds up to vibration and continuous thermal cycling and can withstand temperatures far greater than those for aluminum L-foot finned tubes. Typical fin spacing is 10 fins per inch of tube length — this can be varied.

The following table shows common embedded finned tube configurations:

| Tube OD | 1”, 1-1/4” and 1-1/2″ |

| Tube Wall | .083″ minimum |

| Fin Height | 1/2” and to 5/8″ |

| Fin Type | Solid |

| Fin Thickness | 0.016″ |

| Number of fins | 8 to 11 fin per inch |

| Fin Material | Aluminum 1100-0 |

| Tube Material | Generally carbon steel or stainless steel |

| Tube Length | No practical limit |

* This table should be used as a general guide to our capabilities for embedded finned tubes. Grade of material, tube outside diameter to fin height and other factors may limit these capabilities. Please call us for guidance when designing your next finned tube.

Embedded finned tubes are typically used in higher temperature applications where temperatures may exceed 750 F. Applications include gas compression, process cooling and lube oil cooling.

Embedded finned tube main characteristic

1. Embedded finned tube Max. Working Temperature: 400 °C

2. Embedded finned tube Atmospheric Corrosion Resistance: OK

3. Embedded finned tube Mechanical Resistance: Poor

4. Fin and bare tubes connect tight than normal tension wound on edge fin type

Embedded finned tubes offer solutions where higher temperatures, continuous thermal cycling and tube vibration due to high velocity air streams can cause failures. The fin is mechanically embedded into a groove that is plowed in the tube O.D. and is locked into place by rolls that force the groove to tightly close around the fin base. Embedded finned tubes are commonly used in applications with metal temperatures up to 750 degrees Fahrenheit.

Embedded finned tube applications

Embedded finned tubes have various applications in heat transfer systems where enhanced heat exchange efficiency is desired. Some common applications include:

1. Heat Exchangers: Embedded finned tubes are widely used in heat exchangers for industries such as HVAC, refrigeration, power generation, chemical processing, and oil and gas. They provide increased surface area, which improves heat transfer between two fluids, such as in air-to-air or liquid-to-liquid heat exchangers.

2. Air Cooled Heat Exchangers: Embedded finned tubes are utilized in air-cooled heat exchangers (ACHE) where cooling is achieved by passing air over the finned tubes. These applications can be found in power plants, refineries, petrochemical plants, and other industrial facilities.

3. Radiators: Automotive radiators often employ embedded finned tubes to enhance the heat dissipation from the coolant circulating through the tubes. The fins increase the surface area in contact with the air, resulting in efficient cooling.

4. Condensers and Evaporators: Embedded finned tubes are commonly used in condensers and evaporators of refrigeration and air conditioning systems. They facilitate heat transfer between the refrigerant and the surrounding medium, improving the overall performance of the system.

5. Waste Heat Recovery: Embedded finned tubes can be employed in waste heat recovery systems, where heat from industrial processes or exhaust gases is captured and utilized for other purposes. The enhanced heat transfer provided by the fins improves the efficiency of heat recovery.

6. Boilers: In boilers, embedded finned tubes can be utilized to increase heat transfer efficiency and improve overall performance. They are commonly found in industrial boilers used in power plants, refineries, and other large-scale applications.

7. Process Heating and Cooling: Embedded finned tubes find applications in various process heating and cooling systems where efficient heat exchange is crucial, such as in chemical processing plants, food processing, and pharmaceutical industries.