Product Name: H Type Boiler Finned Tube Welding Machine

- Leave Your Message

Description of H type boiler finned tube welding machine:

This welding machine is special designed for producing H-gilled fin tubes, both single-tube and double-tube, used in boilers.

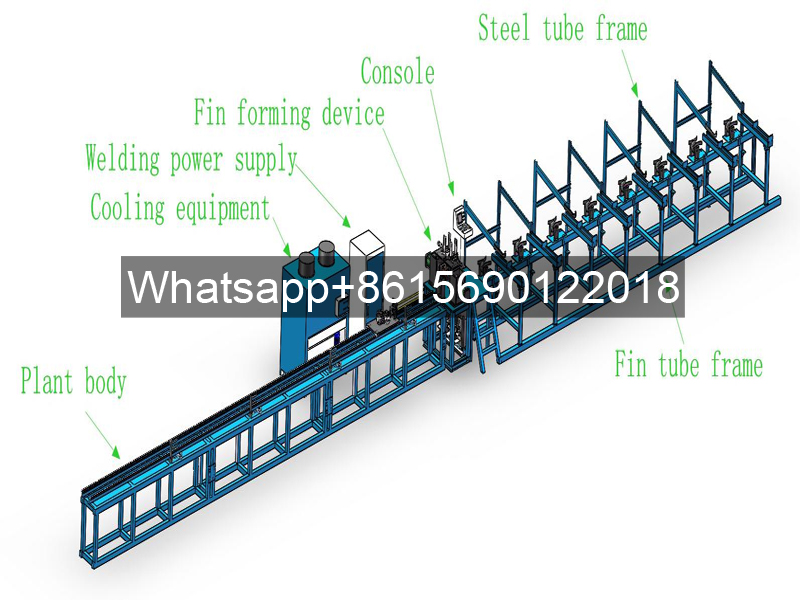

This welding machine is comprised of pushing trolley, pneumatic system, welding head and supporting racks.

This welding machine is PLC control, semi-automatic, manually load steel pipes and unload fin tubes, manually load fins to fin-hopper, hopper automatically feed fins to welding head.

The fin welding pitch and length can be pre-set in PLC. And the welding pitch can be varied on the same fin tube.

H Gilled Boiler Fin Tube Welding Machine

H Type Fin Tube Welding Machine Manufacturer and Supplier

H Type Boiler Finned Tube Welding Machine Parts

The H-Type Boiler Finned Tube Welding Machine developed by Datang consists of a base and two brackets mounted on the base. It also includes two automatic fin unloading hoppers, two feeding cylinders, two unloading channels, two horizontal push cylinders, and two electrode clamping mechanisms.

1. Utilizing a new fin tube welding process, the fin welds utilize multiple zigzag patterns, ensuring a secure weld, uniform weld formation, and a smooth surface, free of slag inclusions, pores, and weld nubs. The weld penetration rate reaches 97%.

2. The multiple zigzag patterns used in the welds reduce the local stiffness of the fin tube, thereby minimizing the compressive plastic deformation generated during welding. This reduces the longitudinal residual tensile stress near the weld seam and significantly reduces the residual compressive stress in the fins away from the weld seam, significantly minimizing fin wave deformation.

3. 97% weld penetration, uniform, smooth weld surface, and no weld bumps. The expanded heating surface increases the heat transfer coefficient. Furthermore, the expanded heating surface unit features a self-cleaning function, which reduces dust accumulation, clogging, and wear on the heating surface. This reduced wear ensures a reasonable service life for the heating surface.

Double H Finned Tube and Single H Fin Tube

H Type Boiler Finned Tube Welding Machine Parameter

| Category | Parameter | Specification |

|---|---|---|

| TUBES | Tube Diameter Range | 32-51mm (duplex tube)/60mm (single tube) |

| Tube Wall Thickness | ≥3mm | |

| Tube Length Range | 1000-12000mm | |

| Material Options | Carbon steel/Low alloy steel/Stainless steel/High alloy steel | |

| Duplex Tube Center Distance | 70-133mm | |

| FIN | Fin Thickness | 2-3mm |

| Fin Width | ≤60mm | |

| Fin Height | ≤280mm (duplex tube)/≤140mm (single tube) | |

| Fin Density | 8-50mm | |

| Fin Material | Carbon steel/Low alloy steel/Stainless steel | |

| ELECTRIC EQUIPMENT | Welding Transformer Power | 4×160KVA (three-phase) |

| Operating Frequency | 1kHz | |

| Secondary Voltage | 14.3V | |

| Primary Current | 600A | |

| Secondary Current | >50kA | |

| PERFORMANCE | Welding Position from Tube | 50mm |

| TESTING | Tensile Test Standard | Acceptance criteria ≥150MPa |

| POWER SUPPLY | Voltage | 380V (three-phase) |

| Frequency | 50Hz | |

| AIR SUPPLY | Compressed Air Pressure | 4-8kg/cm² |

| COMMERCIAL | Delivery Period | 100 working days |

H Type Boiler Finned Tube Welding Machine Product Features:

The punched and sheared fins are manually stacked into the automatic fin unloading hopper. A feed cylinder automatically unloads the fins, while the steel pipe is transported to the welding position. A horizontal push cylinder drives the electrode clamping mechanism for automatic welding. The electrode clamping mechanism is a key component of the welding machine. Both electrodes have a material receiving and pneumatic positioning mechanism. The push cylinder pushes the fins centripetally, automatically moving them into the welding position and clamping them for welding. Once welding is complete, the clamping is released, the finned tube is manually removed, and the steel pipe is advanced. This simultaneous automatic welding of the steel pipe and fins meets the quality and efficiency requirements of finned tube welding.

Finned tubes are designed to recover waste heat from exhaust gases in power plant boilers, industrial boilers, industrial kilns, and marine propulsion systems, effectively improving fuel utilization. They are enhanced heat exchange elements located at the tail end of the system flue.

The double-H finned tube’s structural design utilizes a separate structure for areas prone to soot accumulation, overcoming the drawbacks of spiral-finned tubes, including soot accumulation, blockage, and gas resistance. It represents an improved version of the spiral-finned tube. Furthermore, the fins of the finned tube are designed as cantilever beams. The fins vibrate under the action of pulsed airflow, further facilitating soot removal.

The double-H finned tube’s expanded heating surface increases the heat transfer coefficient. Furthermore, the expanded heating surface unit features a self-cleaning function, which reduces soot deposition, blockage, and wear on the heating surface. This wear reduction ensures a reasonable service life for the heating surface and is essential for the safe and economical operation of waste heat boilers.

H-Type Boiler Finned Tube Welding Machine Product Advantages:

Currently, the primary production method for finned tubes is argon arc welding or electric welding, where the fins are welded to the outside of the central steel tube simultaneously or in multiple welds. This welding process generates thermal stress and deformation between the steel tube and the fins. This deformation cannot be eliminated by argon arc welding or electric welding, resulting in poor quality and low yield. Manual welding also results in slow finned tube production, making it difficult to meet mass production requirements.

To address these issues, Datang has designed and manufactured the H-Type Boiler Finned Tube Welding Machine specifically for welding double H-type finned tubes. It features a simple structure, easy operation, precise control, and high production efficiency. It welds both fins simultaneously, minimizing fin wave deformation, providing consistent welding quality and a high yield. It has promising market prospects and aims to improve production efficiency for finned tube manufacturers, thereby generating higher profits.