Project Description

- Leave Your Message

ASME SA179 aluminum extruded fin tube for heat exchanger

Ⅰ. ASME SA179 standard analysis

What is ASME SA179?

ASME SA179 is a standard for seamless cold-drawn low-carbon steel tubes for heat exchangers and condensers formulated by the American Society of Mechanical Engineers. The applicable material is carbon steel, the outer diameter range is 3.2–76.2mm, and the minimum wall thickness design ensures pressure resistance. Its application scope includes corrosive environments containing hydrogen sulfide (H₂S) such as chemicals and petroleum.

ASME SA179 material characteristics

Chemical composition: low carbon design (carbon content 0.06–0.18%), manganese content 0.27–0.93%, phosphorus and sulfur limited to less than 0.035%, ensuring high toughness and weldability.

Mechanical properties: tensile strength 360–480MPa, yield strength ≥180MPa, meeting the high-pressure scene requirements of heat exchangers.

II. Technical features of aluminum extruded fin tubes

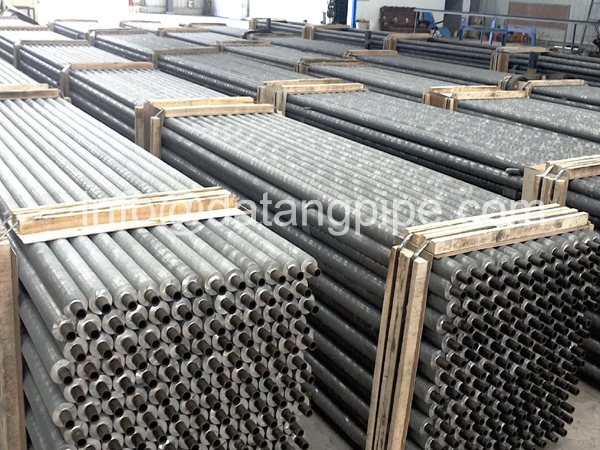

ASME SA179 aluminum extruded fin tube definition and structure

Aluminum extruded fin tubes are formed by hot extrusion process to form a weld-free composite structure with aluminum fins and base tubes (steel/copper/stainless steel), and the base tubes and fins are tightly combined (fin height 5–20mm, density 10–40 fins/inch).

ASME SA179 aluminum extruded fin tube production process

Extrusion molding: The aluminum billet is heated to 480–520℃, and the die is extruded to achieve metallurgical bonding between the fins and the base tube.

Surface treatment: Anodizing or anti-rust coating enhances corrosion resistance.

Core advantages

Thermal efficiency: The fins expand the heat transfer area by 8–12 times, and the heat transfer coefficient is increased by more than 30%; Durability: The aluminum oxide film is resistant to acid and alkali corrosion and does not deform under long-term hot and cold conditions; Safety: The anti-rust coating is non-toxic and suitable for civil and industrial heating systems.

III. Potential relevance of Extruded fin tube standards and applications

Possibility of composite pipes of ASME SA179 aluminum extruded fin tube

If the base tube of aluminum extruded fin tube adopts ASME SA179 steel tube (compatible outer diameter range), “steel-aluminum composite fin tube” can be formed. This kind of structure has both the pressure bearing capacity of SA179 steel tube and the efficient heat transfer characteristics of aluminum fin, but it needs to be verified by customized process whether it meets the dual standards.

Application scenarios of ASME SA179 aluminum extruded fin tube

Industrial field: gas boiler waste heat recovery, petrochemical reactor cooling system; Civil field: central air conditioning condenser, district heating equipment.

IV. Extruded fin tube testing and certification requirements

ASME SA179 aluminum extruded fin tube base tube testing

Chemical composition analysis: verify that the content of elements such as carbon and manganese meets the SA179 standard; Mechanical test: confirm the tensile/yield strength through tensile test.

ASME SA179 aluminum extruded fin tube inspection

Size accuracy: laser scanner verifies fin height and spacing tolerance (±0.1mm);

Non-destructive testing: eddy current testing to check for defects in the interface between the base tube and the fin.