Project Description

Integral threaded low fin tubes for heat exchanger-Fin tube manufacturer

- Leave Your Message

Integral threaded low fin tubes for heat exchanger

Integral low fin tubes

Integral low fin tubes are mainly used in condensers and evaporators in air-conditioning and refrigeration equipment, absorption refrigerators, oil coolers and other various heat exchangers; used in condensers and evaporators in heat exchangers in thermal power plants and nuclear power plants, condensers and evaporators in marine exchangers; used in air coolers, diesel coolers, secondary coolers and various heat exchangers in waste heat recovery systems used in gas turbine units and the petroleum industry, and dryers and heaters used in the chemical industry.

Integral low fin tubes are made by rolling out continuous spiral fins on a light tube. Compared with a light tube, it has a larger surface area and higher heat transfer performance, so it is widely used in various heat exchange and conduction occasions.

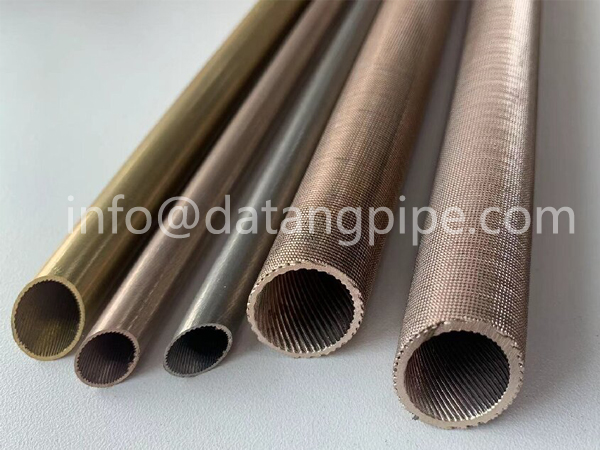

Microfin tubes-low fin tube-integral finned tubes

Low fin tube are mainly used in the condnsers and evaporators for air cooler and refrigerator, absorption refrigerator, oilcooler and other heat exchangers. And other industry such as coal power stations, nuclear power stations,boat heatexchangers, air cooler. Heat recovery system, dryers and heaters in chemical industries.

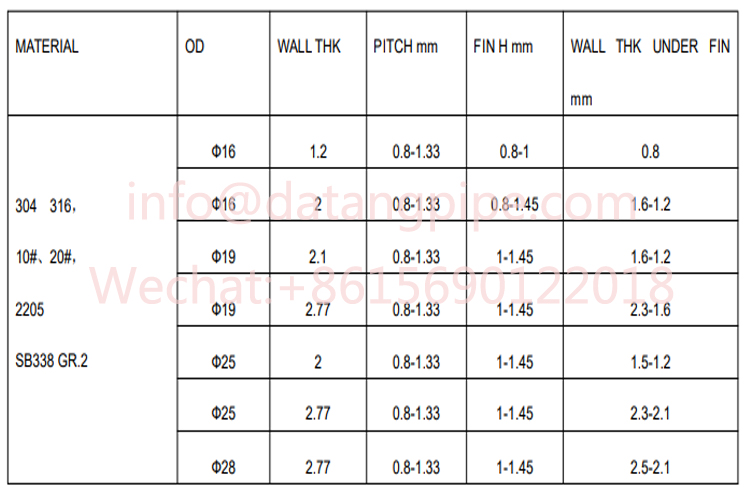

Tube Material: Carbon Steel, Stainless Steel, Aluminium, Copper, Brass,Titanium

SB111 C12200/ C68700/C44300 /C71500 /C70600SA179/SA192/SA106/SA334 Gr.6/SA106Gr.B/SA210 A1/ SA213 T11SA213 TP316L/TP304/ A789 S32205/ SB167 N06625/UNS08825 ASTM B338 Gr2

Bare tube OD: 8-25mm

Fin Pitch: 32FPI-19FPI

Fin Height: 0.6-1.5mm

Fin Thick: 0.25-0.33mm(fin top)

Capacity: Four fining lines, daily capacity

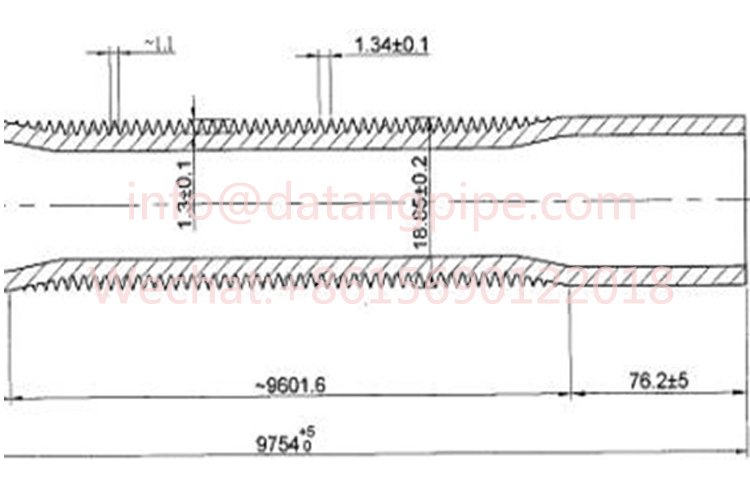

Low fin tube drawing

Low fin tube specification drawing

Threaded low fin tube

- Principle of threaded lowfin tube

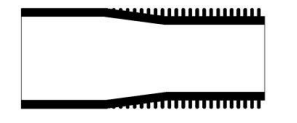

Threaded low fin tube is a high-efficiency heat exchange tube type with threaded fins formed on the outer surface of ordinary heat exchange tubes after rolling. Its structure is shown in the figure:

low fin tubes for heat exchangers structure

The strengthening effect of this tube type is outside the tube. On the one hand, the strengthening effect on the medium is reflected in the increase of heat exchange area by the threaded fins; on the other hand, when the shell-side medium flows through the surface of the threaded tube, the surface threaded fins have a segmentation effect on the laminar boundary layer, thinning the thickness of the boundary layer. Moreover, the turbulence formed on the surface is also stronger than that of the light tube, further thinning the thickness of the boundary layer. As a result of the combined effect, this tube type has a higher heat exchange capacity.

Integral finned tubes-Fin tube manufacturer-info@datangpipe.com

When this tube type is used for evaporation, it can increase the number of bubbles formed on the unit surface and improve the boiling heat transfer capacity; when used for condensation, the threaded fins are very conducive to the dripping of the condensate at the lower end of the tube, thinning the liquid film, reducing thermal resistance, and improving the condensation heat transfer efficiency.

- Characteristics of threaded low-fin tube

⑴ Low processing cost;

⑵ Wide application. It has an enhancing effect on the evaporation, condensation, gaseous heat transfer and liquid heat transfer of the shell side medium.