Project Description

Welded Longitudinal finned tubes(Сварные продольные оребренные трубы)

- Leave Your Message

Welded Longitudinal finned tubes are a type of heat exchanger tube that has fins welded to the outer surface in the direction of the tube’s length.

Welded Longitudinal finned tubes are used to give a great performance in any heat transfer application, especially in petrochemical area. They are the heart of heat exchangers that use their effective characteristics.

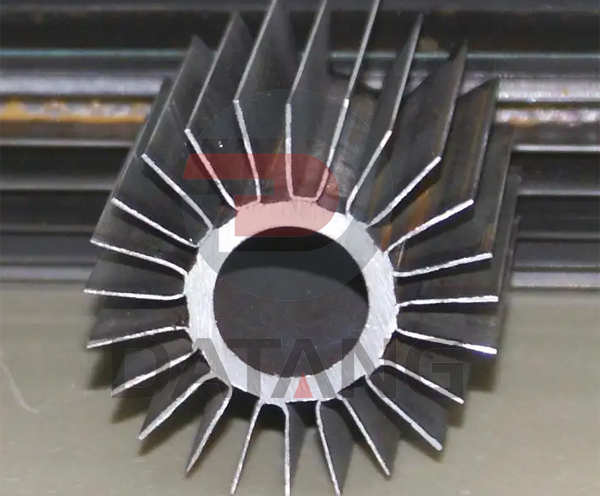

The finned tube are particularly efficient as the channels are welded on the external surface of the tube by means of resistance weld technique. Every channel is the result of a fin strip shaped into a U-form, such that each leg of the U will form a fin. The number of fins will be always a multiple of four with a maximum number depending on the outside diameter of the tube and on the thermodynamic calculations promoted for a specific job.

This resistance weld gives the channels a very high adhesion to the external surface of the tubes. This characteristic grants a great heat transfer efficiency, so that thermodynamic calculations can also design heat exchangers equipments at the best way .

We can also supply finned tubes with perforated fins ( e.g. for use with heaters B5 type ) as well as cut and twist configuration. U-Bend longitudinal finned tubes in single piece construction or with circumferential weld of bends are possible and belongs to the specialities we can offer.

For possible combinations of materials and dimensions you can find here some information about the most used configurations. We are always available to check new technical solutions on your request.

Longitudinal I/L or U-finned tubes are produced from resistance welded fins along the length of the tube. The fins first form a U-shaped channel so that each leg of the U forms a fin. Channels are cut to the appropriate length, then oriented and resistance welded in place along the length of the tube. The channels are welded in pairs, diametrically opposed, so the number of fins specified must be a multiple of 4.

For a given tube or tube size, the desired heat transfer surface area per unit length of tube can be obtained by specifying the appropriate fin height and number of fins. The number of large fins depends on the outer diameter of the tube – larger OD tubes can accommodate more fins.

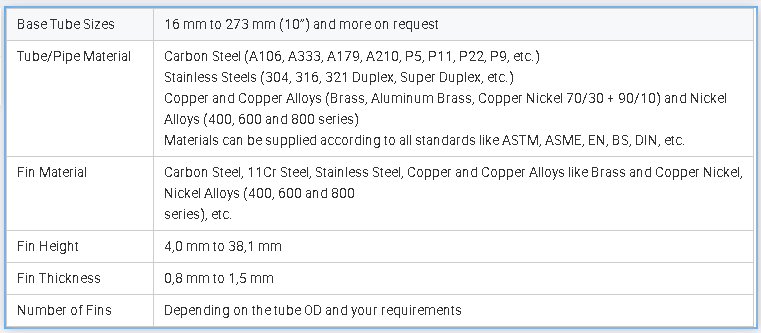

Technical Product Sheet

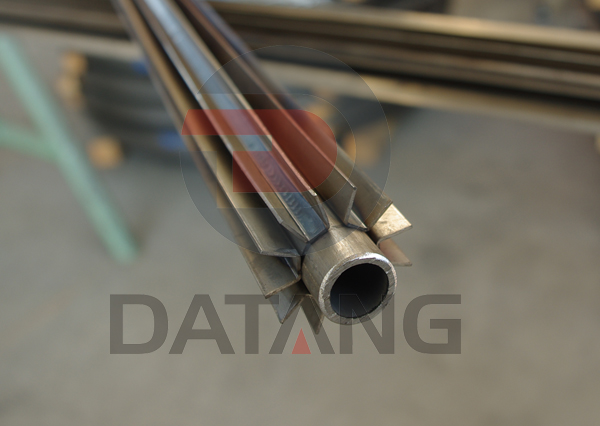

Welded Longitudinal finned tubes drawing

Welded Longitudinal finned tubes

The case of longitudinal finned tube for heat exchangers

Longitudinal finned tube

Longitudinal Fin Tube

Features of longitudinal finned tube

- Efficient and effective bond of fin to tube under all conditions of temperature and pressure

- Ability to withstand high fin-side temperatures

- Provide 8 to 12 times the heat transfer area of bare tubes

- More efficient than bare tubes

These features make longitudinal finned tubes a popular choice for heat exchangers in various industries where high thermal efficiency is required.

Application of longitudinal finned tube

Longitudinal fin construction is commonly used in shell and tube applications.

The choice of longitudinal finned tube versus helical finned tube seems to depend primarily on geometrical factors. For example, some heater structures consist of finned tubes inserted within other tubes – longitudinal finned tubes are the obvious choice for this type of application. In other cases, users prefer a longitudinal finned tube installation, where the tubes will be in a vertical orientation – the finned orientation facilitates fluid drainage on one side of the finned tubes. Longitudinal finned structures are commonly used in shell and tube applications, such as in double-tube and multi-tube heat exchangers, where the longitudinally finned tubes are telescoping within the holes of a larger tube shell. Heat is transferred between the fluid flowing through the finned tube holes and the fluid flowing through the housing holes. Fluid flowing through the housing holes is forced to flow between the longitudinal fins. In this case, the helical fins would block the flow of fluid rather than allow fluid to flow between the fins.

Classification

Specific classification of finned tubes, there are lot of types of finned tubes, meanwhile also lot of new species comes up.

According to the classification process

- rolling forming finned tubes (extruded fin tube);

- welded finned tubes ( high frequency welded finned tubessubmerged arc welded finned tubes,

- roll forming finned tube

- set forming finned tube

- casting finned tube

- the tension wound finned tubes

- inserts the tube .

According to the fin shape classification

- square fin tube (Square finned tube);

- round finned tube

- spiral finned tube (spiral finned tube);

- the vertical fin tube (Longitudinal Finned Tube)

- corrugated fin tube

- serrated spiral finned tubes (Helical Serrated Finned Tubes);

- the needle finned tube

- the overall plate- fin tube ( plate-fin,

- the finned tube (inner finned tube).

And so on.

Depending on whether the finned tubes finned tube material and the same material can be divided into groups

- a single metal finned tube

- bi-metal composite finned tube

A single metal finned tube Material Classification

- copper finned tubes

- aluminum finned tube

- carbon steel finned tube

- stainless steel finned tube

- iron ( steel, finned tube etc. .

By use classification

- air conditioning with finned tubes

- air-cooled with finned tubes

- the boiler : finned water wall economizerair preheater tubes were used

- industrial waste heat recovery with finned tubes

- other special purpose finned tube etc.

The material certificate including all the tests can be provided, and also with EN10204 3.1standard.