Threaded Low-Finned Tubes: Principle and Characteristics

1. Principle of Threaded Low-Finned Tubes

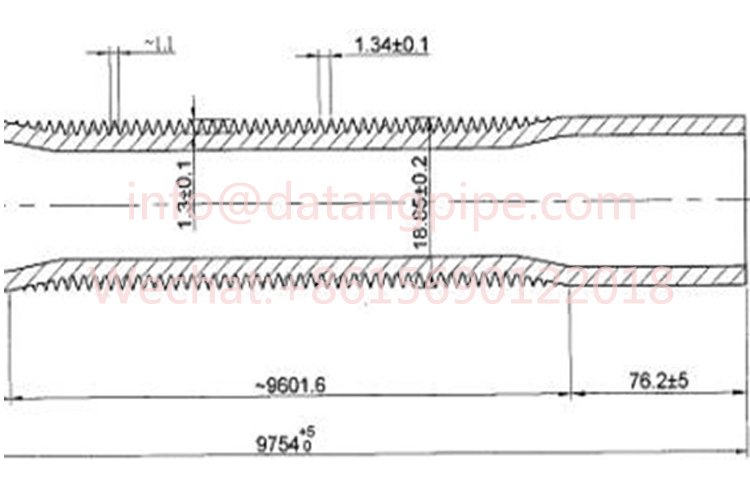

Threaded low-finned tubes are a type of heat exchanger tube where threaded fins are rolled onto the outer surface of a standard heat exchanger tube.

The heat exchange enhancement effect of this tube type is on the outside. The enhancement effect on the medium is manifested in two aspects: firstly, the threaded fins increase the heat exchange area; secondly, when the shell-side medium flows across the surface of the threaded tube, the surface threaded fins segment the laminar boundary layer, thinning its thickness. Furthermore, the turbulence formed on the surface is stronger than in a smooth tube, further thinning the boundary layer.

low fin tube-Datang fin tube-www.datangfintube.com

The combined effect results in a high heat exchange capacity for this tube type. When used for evaporation, this tube type can increase the number of bubbles formed per unit surface area, improving boiling heat transfer capacity; when used for condensation, the threaded fins facilitate the dripping of condensate from the lower end of the tube, thinning the liquid film, reducing thermal resistance, and improving condensation heat transfer efficiency.

C70600 Copper Nickel Integral T-Shaped Finned Tubes Low Fin Tubes for Heat Exchangers

2. Characteristics of Threaded Low-Finned Tubes

⑴ Lower processing cost;

⑵ Wide applicability. It enhances the evaporation, condensation, gaseous heat transfer, and liquid heat transfer of the shell-side medium.

Applications of threaded low-finned tubes:

Threaded low-finned tubes can be used as heat exchange elements to form high-efficiency low-threaded finned tube heat exchangers, as long as the shell-side medium is relatively clean, non-corrosive, and free from scaling.

Copper Inner Grooved Plowed Low Fin Tube Rolling Forming Extruding Machine