Project Description

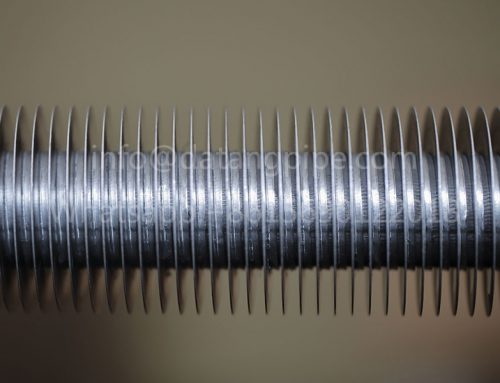

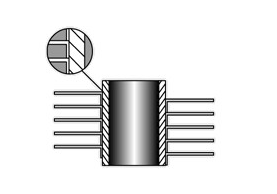

The fin is wrapped around the tube and the foot is rolled into the outer surface of the pre knurled tube and secured at each end. Gives good surface protection to the tube and improved heat transfer compared to the L or LL type fin. KL -Foot tension wound finned tubes are commonly used in applications with metal Maximum Operating Temperature- up to 320°C (608°F)

Advantages of the KL Type Fin Tubes

Tube protected against corrosion

Medium temperature applications

Increased fin to tube bond

Greater thermal contact than standard L fin

Added heat transfer performance due to the knurling

Increased atmospheric corrosion protection of the core tube

Good stability

Resistant to vibrations

May be used at temperature up to 320°C (608°F)

Unique combination of high thermal performance and stresses resistance with atmospheric corrosion protection

KL can favorably replace any type of finned tubes

Manufactured method is exactly as the L finned tube except that the base tubes are knurled before application of these fin foot. After application, the fin foot is knurled into the corresponding knurling on the base tube thereby enhancing the bond between the fin and tube, resulting in improved heat transfer characteristics.

Base Tube materials: Any material available, such as Carbon Steel/ Carbon Alloy Steel/Stainless Steel/ Nickel Alloys/ Copper/Copper Alloys/Titanium, A179, A192, A210, stainless tube A269/A213 T5 T11 T22 304 316

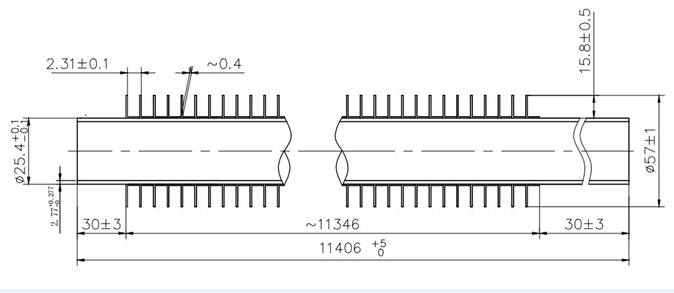

Tube Diameter:1/2” (12.7mm) to 2” (50.8mm)

Tube Wall Thickness:> 0.049” (1.244mm) depending on tube material and outside diameter

Fin Heights:1/4” (6.35mm) to 1” (25.4mm)

Fin Pitches:5 to 12 fins per inch

Fin Strip Thickness:0.012” (0.30mm) to 0.020” (0.50mm)

The fin is wrapped around the tube and the foot is rolled into the outer surface of the pre knurled tube and secured at each end. Gives good surface protection to the tube and improved heat transfer compared to the L or LL type fin. This finned tube is used for moderate temperature cooling applications.

Upper Temperature limit: 250°C

Tube Material: Any standard material we stock or is requested

Fin Material : Aluminium or Copper

In order to forward you a promt offer we would be pleased to receive you detailed enquiry including:

• Base tube material

• Base tube size (OD x WT x Length)

• Fin material

• Fin type

• Fin diameter or height

• Fin thickness

• Fins per inch, meter or fin pitch

• Lenght of plain, unfinned ends

• Finned Tube Quantity

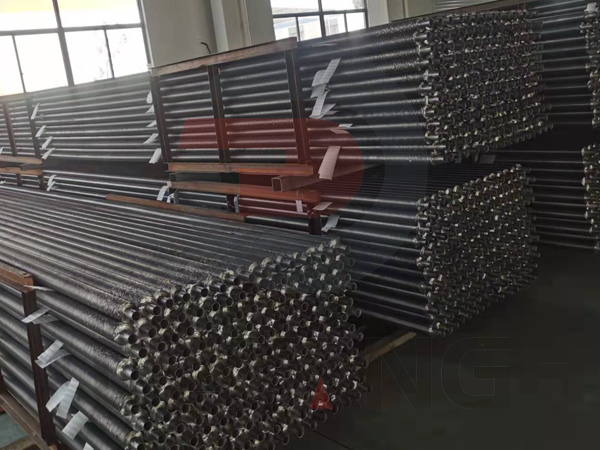

Cangzhou Datang Steel Pipe Co., Ltd located in Cangzhou City,the hometown of pipelines, is a collection of research and development, production, sales in one of the enterprises. The company was founded in 2007 with registered capital 10.08 million RMB, and through the IS09001 international quality system certification, we has high frequency resistance welding finned tube production line 18, extruded finned tube equipment 30, laser welding finned tube production line 2, wound finned tube production line 12. The annual capacity can reach 100,000 tons, the specification φ 18-273mm finned tube, according to the customer requirements of the standard production, service has exceeded 3000+ enterprises.

Our companys tenet is to be Chinas most professional pipeline and equipment suppliers, on the basis of seamless steel tube, integrate the national high quality pipe equipment resources, provide one-stop packaging services,quality makes customer trust, service makes customer relieved, result makes customer comfort, building a conscience, good-hearted, have the sense of responsibility, contributes to the society of the enterprise.Our slogan is professional concentrate in pipeline & accessories 20 years.

Inquiry and consulting support.

Sample testing support.

Visit our factory

After-sales service

Training how to install the tubes, and maintenance.

Engineers available to service overseas.

FAQ

Are you a manufacturer?

We are a professional manufacturer focus on the fin tube area.

Does free shipping is possible?

We don’t offer a free shipping service, but we will offer a discount depends on the quantity.

Do you make OEM?

Yes, we do. We manufacture according to your design and brand standards.

How about the delivery time?

According to the sizes and quantity, delivery time is different. We transport by sea and air normally.

Maintenance

We ensure our standards against erosion and provide professional maintenance advice, for quality advice, we can guarantee for one-year after-sales.