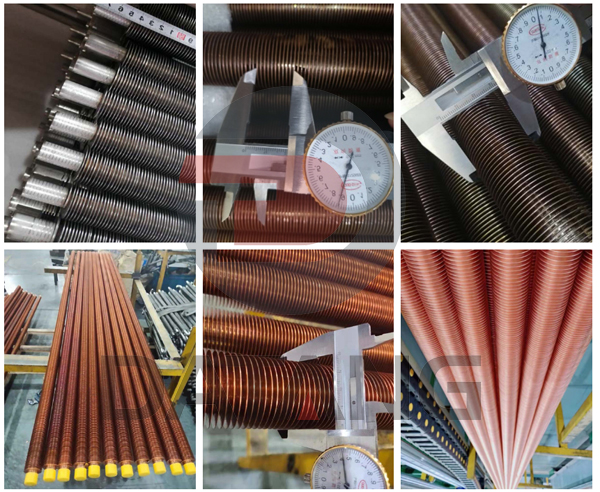

Laser welded finned tubes ( Laser welding fin tubes ) 4 laser welded fin tube machines with a daily productivity of 2000 meters

Laser welded finned tubes are used in civil wall-hung boilers, industrial boilers, etc., using German technology, which is just emerging in China, but has a history of more than ten years in Europe. The advantage is that the contact thermal resistance is zero, and compared with high-frequency welding, it has finned The heat exchanger has the characteristics of large ratio, light weight, compact size, more energy saving and environmental protection, and meets the national emission requirements.

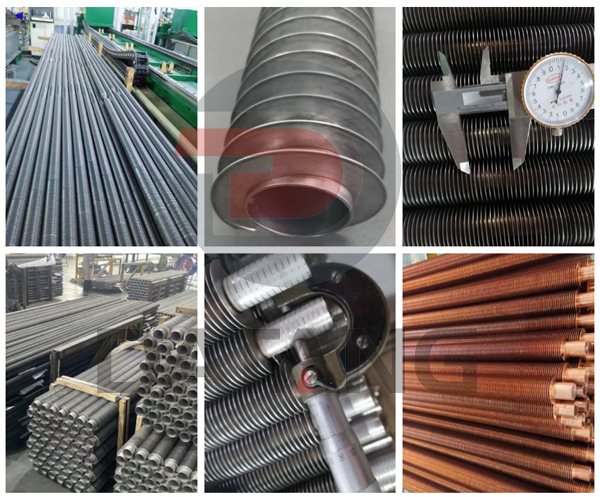

Laser welded stainless steel finned tube

Laser welded finned tubes are the most technologically advanced products with irreplaceable advantages

1: The thickness of the base tube can be 0.8-1.5 mm, and the thickness of the fins can be 0.3-1 mm, which greatly saves the material cost compared to other processes.

2: High penetration rate, can prevent crevice corrosion, prolong service life, and reduce heat transfer resistance.

3: Breaking through material limitations, different materials can be used for processing.

4: Easy secondary processing, can be directly coiled and bent.

5: The welding heat-affected zone is small and the metallographic change is small, making it possible to process small diameter finned tubes.

The materials used for heat exchange tubes and condenser tubes should have excellent heat transfer performance, as well as good corrosion resistance, erosion resistance and abrasion resistance, as well as good strength, stiffness and plasticity, and are easy to process and manufacture.

Laser welded copper finned tube

There are many kinds of finned tubes, mainly high-frequency welded finned tubes. Although it is more advanced in product quality and production automation compared with inlay, brazing and other methods, due to the high frequency welding finned tubes. Factors such as difficult penetration of the root and wrinkles at the root lead to many deficiencies in the heat exchange efficiency and the convenience of preventing fouling of the high-frequency welded finned tube. In view of the above reasons and in response to the national policy on energy conservation and emission reduction.

Laser welding finned tube adopts laser welding process, which can weld light pipes and fins with thinner wall thickness, as well as denser fin pitches. Thinner light pipes and dense fins can improve heat exchange efficiency. Good penetration rate and not easy to be pulled off are the foundation of its good service life.

Laser welding finned tubes can realize welding between different metals, which can achieve good heat exchange efficiency for customers under different working conditions, and thinner wall thickness is also one of the ways to save costs.

Our laser welding finned tubes have stable process and good price. It has provided support for the product innovation of various energy enterprises and provided opportunities for the development of enterprises. Laser-welded finned tubes have higher heat transfer performance and lower material costs than high-frequency welded finned tubes, and will become a market development trend.

Laser welded pipe processing size and parameters

Material name: stainless steel + stainless steel, stainless steel + carbon steel, stainless steel + copper, carbon steel + carbon steel, carbon steel + copper, copper + copper

| Specification | Wall Thickness mm | Fin Spacing mm | Fin Height mm | Fin Thickness mm | ||

| Φ10 | 1.2-2 | 2-3.5 | <5 | 0.3-1 | ||

| Φ12 | <6 | |||||

| Φ16 | <8 | |||||

| Φ19 | >1.0 | 2-5 | <9 | 0.5-1 | ||

| Φ22 | >1.2 | 2-5 | <11 | |||

| Φ25 | >1.3 | 2-6 | <12.5 | |||

| Φ28 | >1.5 | 2-8 | <14 | 0.8-1.2 | ||

| Φ32 | >1.5 | 2-8 | <16 | |||

| Φ38 | >1.8 | 2-10 | <19 | |||

| Φ45 | >2 | 2-10 | <23 | |||