Project Description

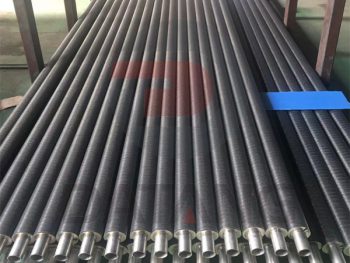

Laser welding finned tube

Laser welding finned tube is processed by laser welding machine. Laser welding is a welding method that irradiates a high-intensity laser beam onto the metal surface. Through the interaction of the laser and the metal, the metal absorbs the laser light and converts it into heat, melting the metal to form a cooling crystal. Laser welding machine is the most advanced laser welding equipment for finned tubes. Because the welding process is fully automatic and mechanical, the scientific and technological content and quality of laser welding finned tubes are superior to traditional cooling tubes.

The laser welding finned tube has a fully automatic welding process, saving manpower costs; secondly, the laser welding fin is firm, strong, and the test with high tensile strength is qualified. Laser welding is more efficient.

Advantages of laser welded finned tube

- The laser welding finned tube (finned tube) fin machine has a high degree of automation, and the welding of the fin to the tube and the winding of the tube are synchronized

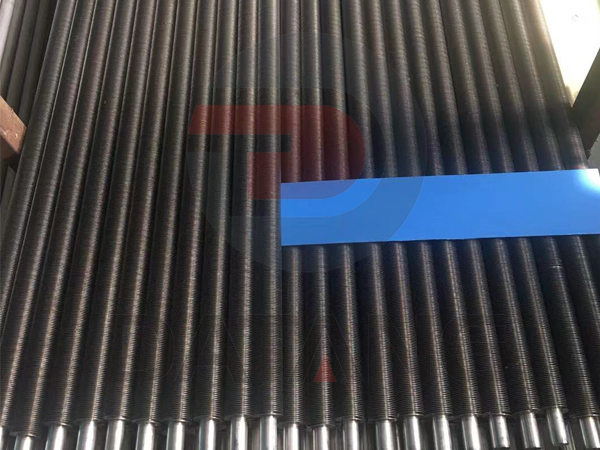

- 100% welding rate, laser welding finned tube and fins are strong, the welding strength exceeds 600MPa.

- The precision of laser welding tube finishing machine is up to 0.05mm

- 0 contact resistance, achieve high efficiency of heat transfer of spiral finned tube by laser welding.

- Save production costs. The laser welding finned tube (finned tube) has a smaller fin spacing, less than 2.5mm. Compared with the high frequency welded spiral (spiral) finned tube, the heat transfer area is increased by about 50%, which makes the material cost Reduced, volume reduced heat exchanger.

- The advantages over conventional MAG / HF welding are of decisive importance. The complete connection between the fin and the base tube brings excellent heat transfer, and the thermal performance of the fin tube is increased by 2.5 times. Continuous welding prevents the notch effect, thereby avoiding the formation of v-corrosion and cracks under the condition that the finned tube may swing. The heating of base metals during welding is low and the travel speed is up to 20m / min. Minimize the heat affected zone in the base tube. Therefore, it does not include the complete melting of the tube and the related metallurgical transformation of the parent metal.

Laser welded finned tube specifications

- Thin and continuous ideal seams

- Small heat affected area

- Slightly discolored welding parts

- The tubes and fins have only slight microstructure changes

- High heat forms seams

- Since the high welding integrity between the tube and the fins is avoided, the crevice corrosion is avoided, thereby improving safety

- Laser welding is carried out in a protective atmosphere, so the weld is free of impurities

Laser welded finned tube Application

Power Plants

- Cooling towers or cooling water recooling plants with dry, dry / wet or wet operation

- Flue gas cooling and heating in flue gas desulfurisation scrubbers (FGD) and nitrogen removing plants (DENOX)

Chemical Industry

- Heat exchangers of all kinds for cooling and heating of liquids and gases

- Heat exchangers tor nitric acid (HNO3) plants, e.g. for the fertilizer industry

Heat Recovery Plants

- Flue gas coolers

Heating Industry

- Primary heat exchangers in gas heating boilers

- Secondary heat exchangers for domestic water heating in condensing boilers

General Engineering

- Heat exchangers for gas cooling of industrial furnaces

- Heat exchangers for tank heating

- Oil coolers for vacuum plants, ship plants, pumps etc.

- Heat exchangers for oil preheating

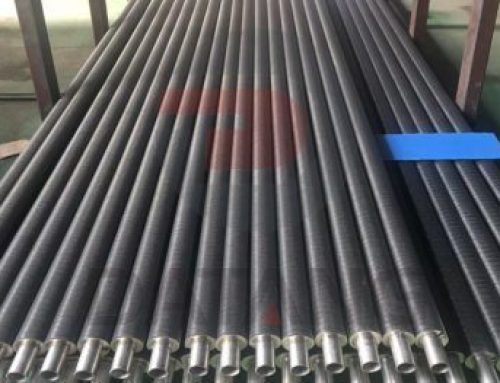

Dimensions

- Tube outside diameter 8.0–50.0 mm

- Fin outside diameter 17.0 –80.0 mm

- Fin pitch 5 –13 fin/inch

- Fin height 5.0 –17 mm

- Fin thickness 0.4 – 1.0 mm

- Maximum tube lengths 12.0 m

Cangzhou Datang Steel Pipe Co., Ltd located in Cangzhou City,the hometown of pipelines, is a collection of research and development, production, sales in one of the enterprises. The company was founded in 2007 with registered capital 10.08 million RMB, and through the IS09001 international quality system certification, we has high frequency resistance welding finned tube production line 18, extruded finned tube equipment 30, laser welding finned tube production line 2, wound finned tube production line 12. The annual capacity can reach 100,000 tons, the specification φ 18-273mm finned tube, according to the customer requirements of the standard production, service has exceeded 3000+ enterprises.

Our companys tenet is to be Chinas most professional pipeline and equipment suppliers, on the basis of seamless steel tube, integrate the national high quality pipe equipment resources, provide one-stop packaging services,quality makes customer trust, service makes customer relieved, result makes customer comfort, building a conscience, good-hearted, have the sense of responsibility, contributes to the society of the enterprise.Our slogan is professional concentrate in pipeline & accessories 20 years.

Inquiry and consulting support.

Sample testing support.

Visit our factory

After-sales service

Training how to install the tubes, and maintenance.

Engineers available to service overseas.

FAQ

Are you a manufacturer?

We are a professional manufacturer focus on the fin tube area.

Does free shipping is possible?

We don’t offer a free shipping service, but we will offer a discount depends on the quantity.

Do you make OEM?

Yes, we do. We manufacture according to your design and brand standards.

How about the delivery time?

According to the sizes and quantity, delivery time is different. We transport by sea and air normally.

Maintenance

We ensure our standards against erosion and provide professional maintenance advice, for quality advice, we can guarantee for one-year after-sales.