Project Description

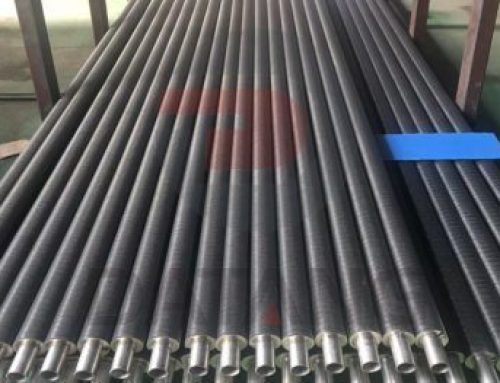

- Product Name: Copper Laser Welded Fin Tube With Copper Tube Cooper Fins

- Leave Your Message

What is Copper Laser Welded Fin Tube?

Copper laser welded fin tube is a heat exchange element that firmly connects copper fins to copper base tubes through laser welding technology. It is mainly used in heat exchange scenarios in the industrial field.

Basic structure of copper laser welded fin tube

It consists of copper base tube and copper fins. The base tube is usually made of pure copper or copper alloy materials (such as copper, brass). The fins are attached to the surface of the base tube through laser welding technology to form an efficient heat conduction structure.

Copper laser welded fin tube manufacturing process

Material preparation: Select high-purity copper as the base tube and fin material to ensure thermal conductivity and corrosion resistance.

Surface treatment: Clean the base tube and fin surface oil, oxide film and other impurities to ensure the efficiency of welding energy transfer.

Laser welding: The copper material is partially melted by a high-energy laser beam to form a metallurgical weld. The laser power and focus position are precisely controlled to optimize the welding quality.

Cooling and testing: After welding, proper cooling is performed, and non-destructive testing is performed to ensure the strength and air tightness of the weld.

Performance characteristics of copper laser welded fin tubes

High thermal conductivity: Copper itself has excellent thermal conductivity, and laser welding further optimizes the heat conduction efficiency, which increases the heat exchange efficiency by 20%-30% compared with traditional fin tubes.

Strong corrosion resistance: Copper has stable corrosion resistance in humid environments and is suitable for corrosive scenes such as chemical industry and electricity.

Firm welds: Laser welding achieves precise melting, avoids the gap corrosion problem of traditional welding, and prolongs service life.

Application areas of copper laser welded fin tubes

Mainly used in chemical equipment heat exchange, power cooling system, oil and gas pipeline transportation and other fields, requiring high thermal conductivity and corrosion resistance in industrial scenes.