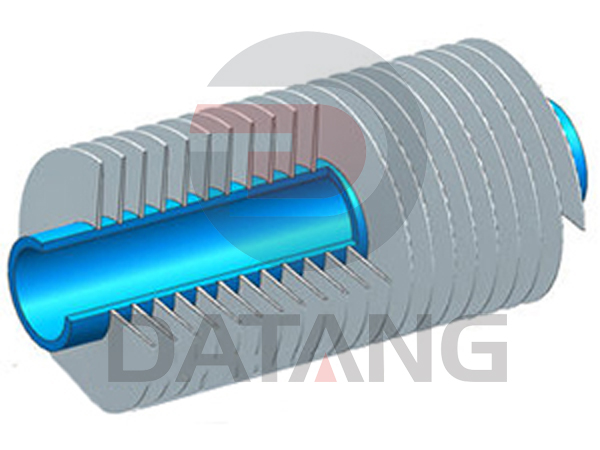

What are the characteristics of G type finned tubes(Embedded Finned Tube)?

G finned tube is also called Embedded Finned Tube.G Type finned tube is one of the widely used threaded finned tubes, which improves the heat transfer performance of thermal elements, except for the defects of tubes and coils. Its total heat transfer area is several to dozens of times larger than that of a light pipe, which can enhance heat transfer and reduce resistance. The same heat exchange method can greatly reduce the size of the facility and the consumption of metal materials, and enhance the economy and reliability of heat exchanger operation.

1. The heat transfer characteristics of G type finned tubes are related to the contact thermal resistance between the finned tubes, and the core of the contact thermal resistance is the contact pressure between them. Obviously, the heat transfer characteristics of the welded chip and the sleeve are better, followed by the bimetallic pipe, and the insertion and winding are poor. After re-crimping, the contact area of the KLM finned tube is increased by about 50% and is not disturbed by the tolerance of the tube outer diameter. After many cold cycles, the contact is good, the contact thermal resistance is small, and the heat transfer characteristics are high. The slotted finned tube can increase the disturbance of the airflow and increase the total heat transfer coefficient by about 20%.

Embedded finned tubes

2. As the wall temperature of the Embedded Finned Tube with room temperature performance increases, the contact pressure between the pin and the tube changes, and the contact thermal resistance also changes. The fluctuation value depends on the type of finned tube and the initial contact pressure. As the temperature increases, the lead tension around the chip decreases rapidly, so the thermal contact resistance increases rapidly. Bimetal rolling is stable over a wide temperature range.

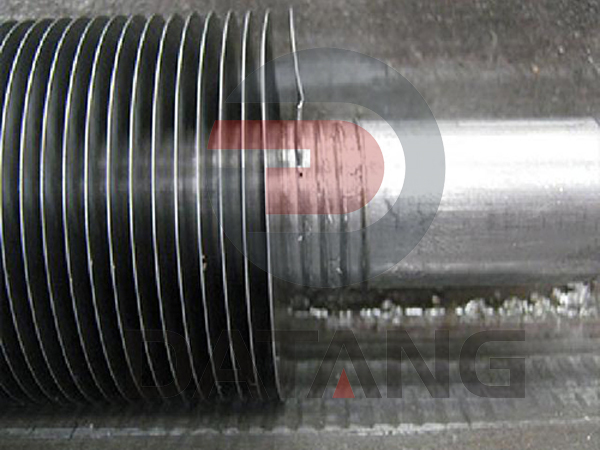

304/316 Stainless steel G-type finned tube

3. The bottom tube of G-type finned tube is protected against atmospheric corrosion by the wing to prevent atmospheric corrosion. Due to the different protection range, the ability of various types of finned tubes to resist atmospheric corrosion is also different. Among the various finned tubes, bimetallic rolling is good. All hot-dip galvanized finned tubes have good atmospheric corrosion resistance. Chemical plants with corrosive gases in the atmosphere should pay special attention to the selection of raw materials and types of finned tubes, and aluminum needles are easy to corrode.

4. In many operations of finned tubes, the pressure is the material and wall thickness selected in the bottom tube, but it is also related to the type of finned tube. Rolling (the bottom tube is made of aluminum and copper) has low pressure resistance and is not suitable for use in air coolers. There are rolling grooves in the bottom tube of the embedded chip, and the working pressure decreases with the increase of the working temperature.

Copper Alloy G-type finned tubes

5. Clean the dirt on the gas side of the dirty Embedded Finned Tube, usually using compressed air, steam or high pressure water. In this way, the fins have corresponding stiffness.

6. Manufacturing costs. Judging from the raw material consumption of the G-finned tube, the circumference is low and the bimetal roll and sleeve are high. Bimetal rolled aluminum consumes 1/3 ~ 1/2 more than cladding. From the perspective of manufacturing and processing costs, the circumference is lower, the bimetal rolling is higher, and the sleeve is higher. All finned tubes that require surface hot dip galvanizing are expensive in terms of raw material consumption or manufacturing process.