The first step in the production of steel and aluminum finned tubes is to purchase steel pipes. The steel pipes first have high compressive strength and high pressure. Low thermal conductivity and good thermal insulation performance. Fluid resistance is small. Aluminum tube series: thick-walled round tube diameter 15mm—160mm, wall thickness 2.0mm-40mm; thin-walled round tube diameter 20mm—130mm, wall thickness 0.8mm—5.0mm。

Extrusion finned tube machine

The extruded finned tubes consists of a base tube and fins wrapped outside. The base tube is usually a carbon steel tube, stainless steel tube or copper tube. The aluminum tube is sleeved on the outside, and then the aluminum tube is extruded into fins with a special rolling mill.At the same time, a thin bottom layer is formed outside the base pipe to tightly wrap the base pipe. The base of the fin is closely attached to the outer wall of the pipe, and the length is from 0.5 meters to 6 meters. It meets the demand for the length of the aluminium extrusion pipe, thereby solving the trouble of re-cutting due to inappropriate length during use.

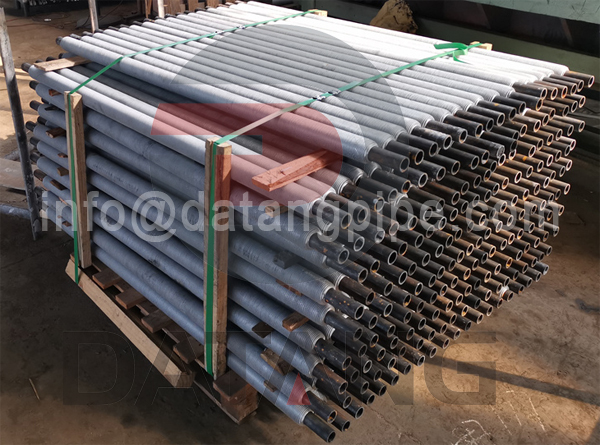

Extruded finned tubes

The advantages of steel-aluminum finned tubes are no burrs, no wrinkles, easy to clean, easy to remove condensed water on the surface of the fins during wet cooling in heating, and not easy to dust and scale in drying heating and other heat exchange occasions. Aluminum-rolled finned tube, the surface is smooth and easy to handle, the color is beautiful and generous, and it can effectively prevent surface corrosion. The mass is lighter, and the proportion of aluminum in the common non-ferrous and ferrous metals is small. Extruded finned tubes are widely used in various industries, such as: textile industry, ships, chemical industry, aviation, food drying, agriculture, electromechanical, household, etc.

Aluminium extrusion pipe