Finned tube is a heat exchange element. In order to improve the heat exchange efficiency, fins are usually added on the surface of the heat exchange tube to increase the outer surface area (or inner surface area) of the heat exchange tube, so as to achieve the purpose of improving the heat exchange efficiency. Such a heat exchange tube.

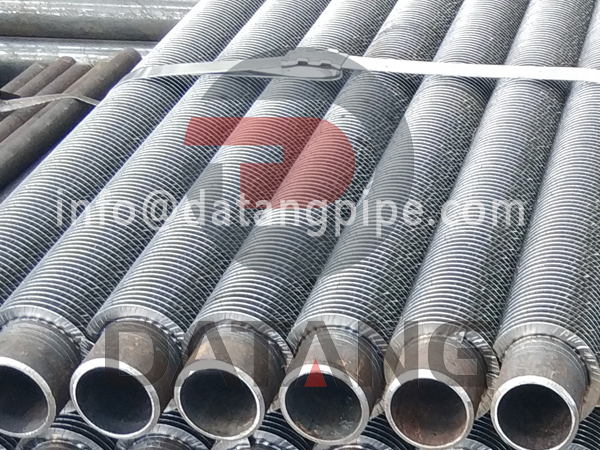

HFW finned tube

The finned tube increases the heat exchange area, and the fins are made of high-quality materials to ensure that the area of the fins meets the standard requirements, so the fins can effectively increase the heat exchange area during the heat transfer process. In addition, the fins of the heat exchanger can be regarded as an additional area of the partition, and the area of the fins is much larger than that of the baffles, thereby significantly increasing the compactness of the structure.

Carbon SS steel Aluminum fin

The finned tube can effectively increase the heat dissipation, and the installation is easy to reduce the connection points, so that the finned tube will reduce the leakage point and improve the service life. It can be widely used in industrial fields such as economizers, waste heat recovery equipment, power plant boilers, greenhouse farming, greenhouses, petrochemicals, and wood drying.

Wound fin tube

To improve the efficiency of heat exchange, the fin structure of the finned heat exchanger has certain characteristics. When the heat exchange is performed, the fluid in the finned tube can form a violent disturbance, so that the thermal resistance can be reduced. Fins can greatly increase the heat exchange efficiency of the overall system.

To enhance the bearing capacity of the heat exchanger, it can not only play a good role in heat transfer, but also support and strengthen the overall effect of the exchanger, making it perform quite well in terms of compression resistance, so it can strengthen the bearing capacity of the heat exchanger ability.