Be.Tube Srl offers different finned tubes: tension wound finned tubes, embedded finned tubes and extruded finned tubes.

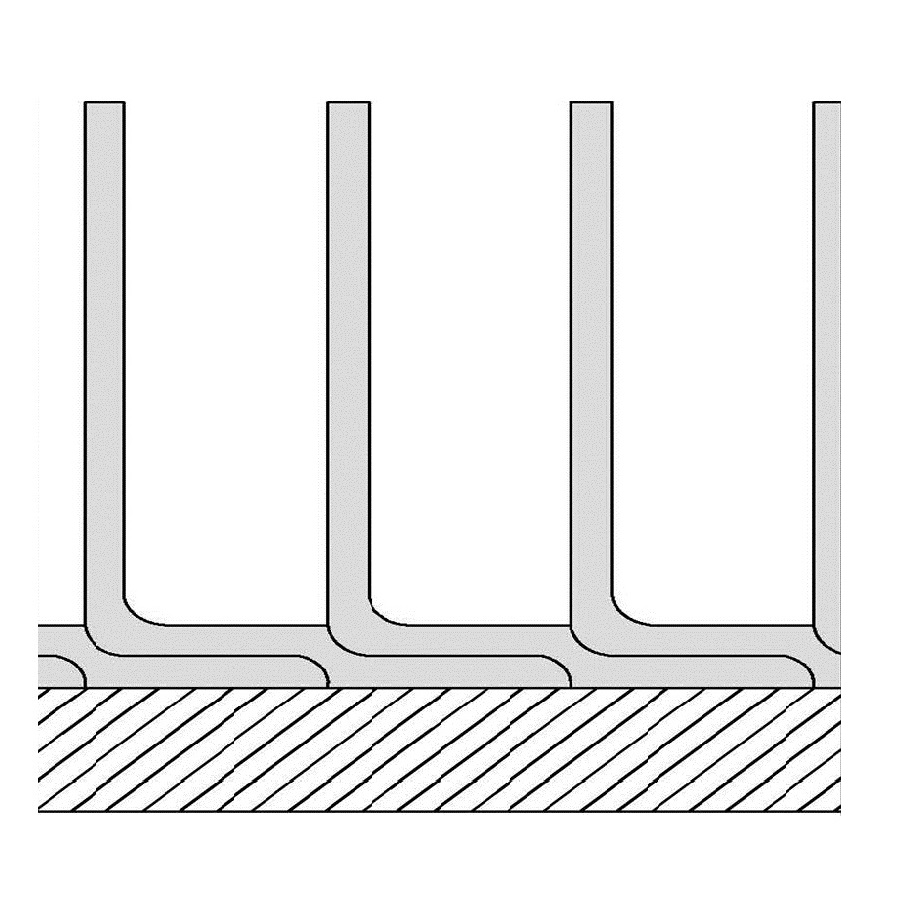

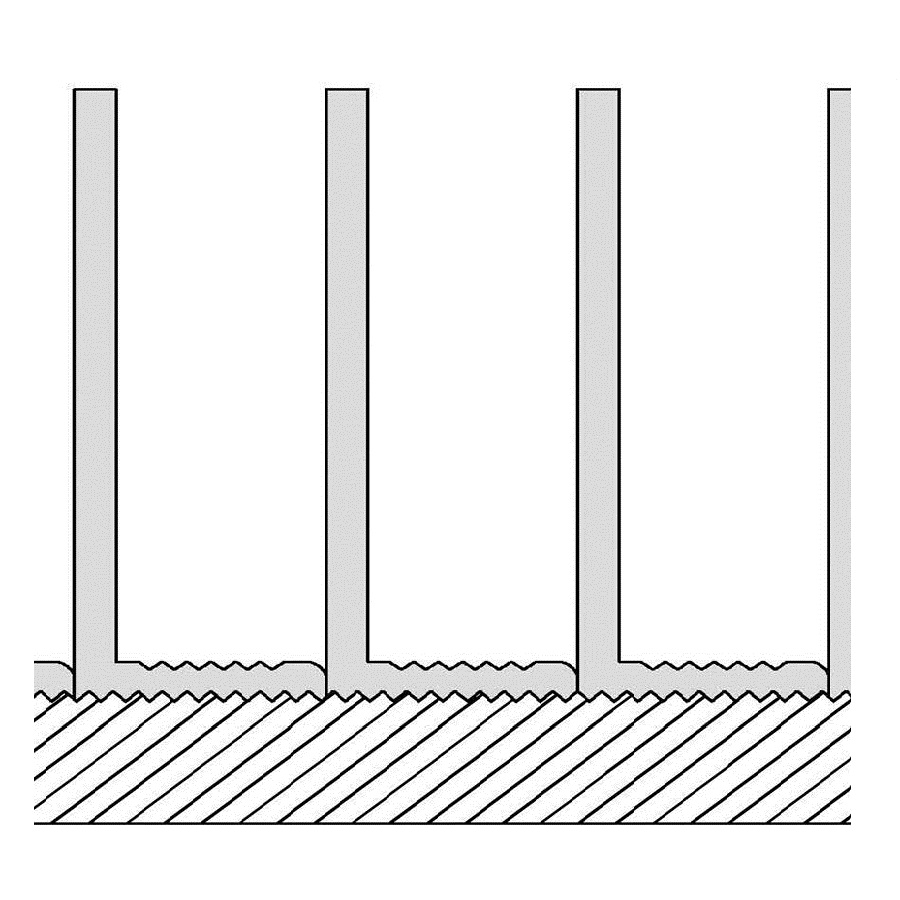

Tension wound finned tubes are formed by winding a strip made of aluminium or copper around the tube under tension. The strip winding technology provides different types of fins: L-Fin, LL-Fin, KL-Fin.

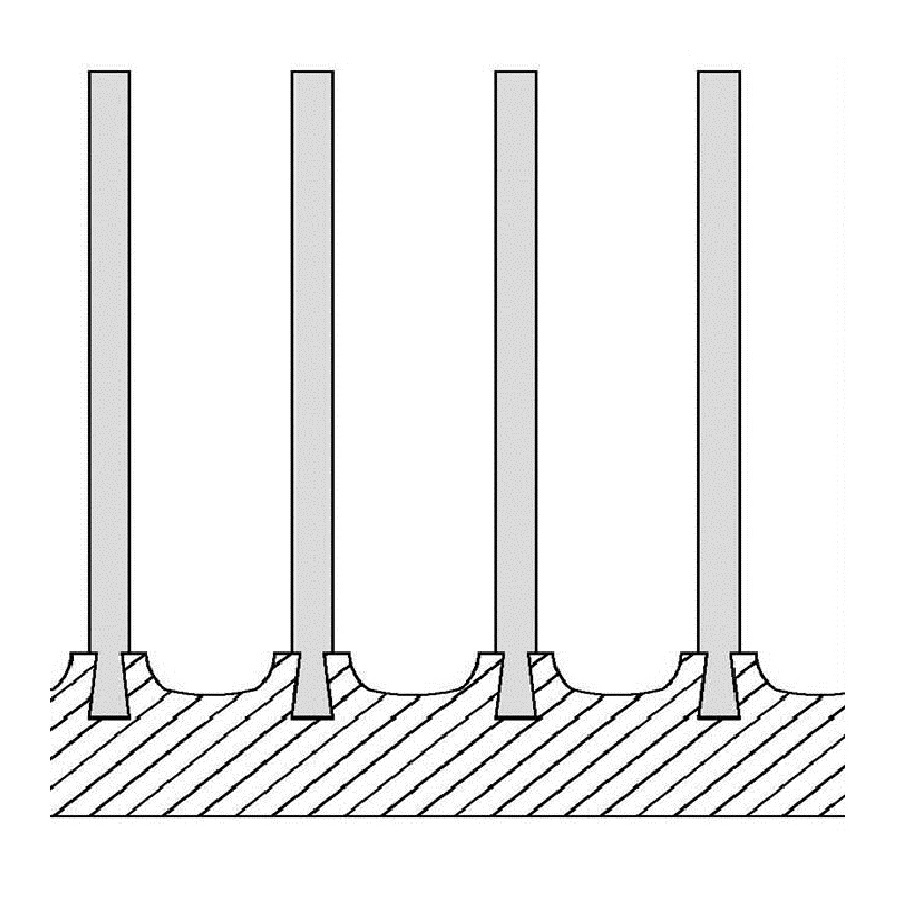

Embedded fins (G-Fins) are made by winding aluminium or copper strip into a helical groove machined on the outer surface of the tube.

| G-fin | L-fin |

|---|---|

|

|

| LL-fin | KL-fin |

|

|

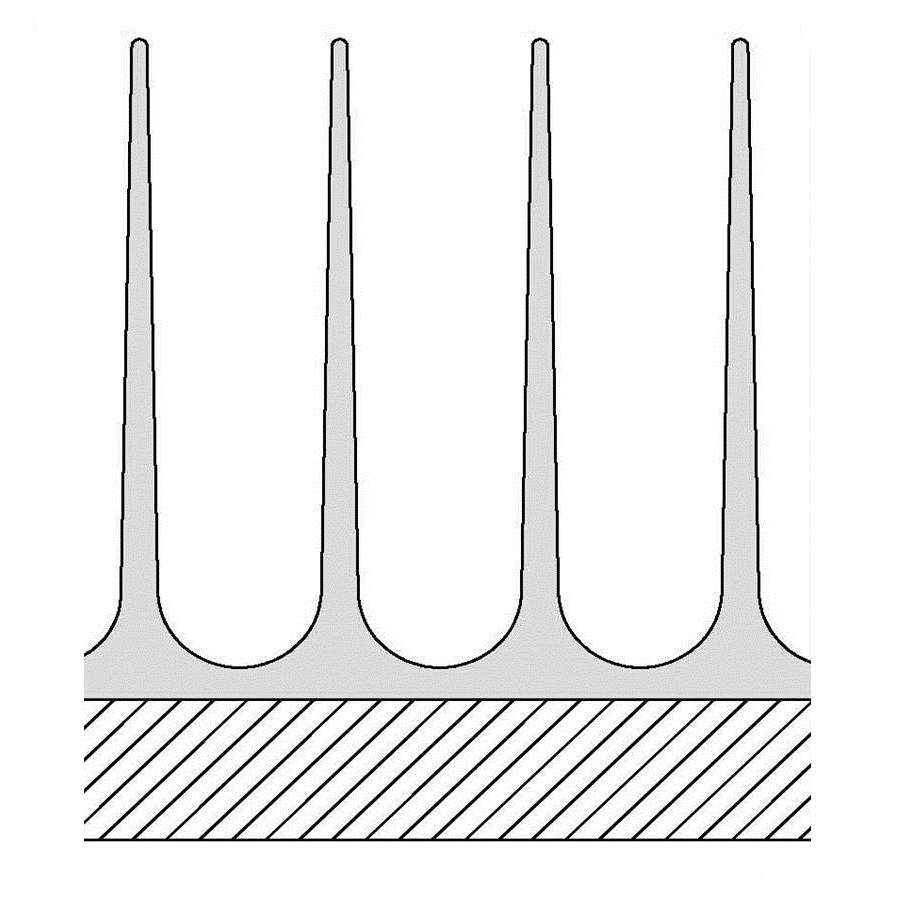

Extruded finned tubes are bimetallic tubes whose outer aluminium surface is finned by cold plastic deformation.

| Extruded-fin |

|---|

|

| Fin Material – Extruded-fin Finned Tubes | ||||

|---|---|---|---|---|

| Fins | SB209 – B209 Aluminium Alloy 1050 or 1060 | SB75 – B75 Copper | ||

| Notes | For different materials please contact our technical office | |||

| Fin Material – G-fin; L-fin; LL-fin; KL-fin Finned Tubes | ||||

|---|---|---|---|---|

| Fins | EN573-3 Aluminium Alloy 1050 or 1060 | SB152 – B152 Copper | ||

| Notes | For different materials please contact our technical office | |||

| Tube Material – G-fin; L-fin; LL-fin; KL-fin; Extruded-fin Finned Tubes | ||||

|---|---|---|---|---|

| Tube | SA179 – A179 Carbon Steel | SA213 – A213 Stainless Steel | SB75 – B75 Copper | SB111 – B111 Copper Alloy |

| Notes | For different materials please contact our technical office | |||

| Technical Specifications – G-fin; L-fin; LL-fin; KL-fin; Extruded-fin Finned Tubes | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fin Types | Length | Tube Diameter | Thickness | Finned Tube Diameter | Fins Density | ||||||||||||||||||||

| L-Fin |

|

|

|

|

|

||||||||||||||||||||

| LL-Fin | |||||||||||||||||||||||||

| KL-Fin | |||||||||||||||||||||||||

| G-Fin | |||||||||||||||||||||||||

| Extruded | |||||||||||||||||||||||||

| Technical Specifications – G-fin; L-fin; LL-fin; KL-fin; Extruded-fin Finned Tubes | ||||||

|---|---|---|---|---|---|---|

| Fin Types | Working Temp. |

|

||||

| L-Fin | 135 ÷ 155 °C |

|

||||

| LL-Fin | 155 ÷ 165 °C |

|

||||

| KL-Fin | 165 ÷ 185 °C |

|

||||

| G-Fin | 380 ÷ 420 °C |

|

||||

| Extruded | 280 ÷ 300 °C |

|

||||

| Inspections and Tests G-fin; L-fin; LL-fin; KL-fin; Extruded-fin Finned Tubes |

|---|

| Chemical Composition |

| Mechanical Properties |

| Hydrostatic Test |

| Pneumatic Test |

| Boroscopic Inspection |

| Eddy Current Test |

| Tensile Test (only for bimetallic tube) |

APPLICATIONS – G-FIN; L-FIN; LL-FIN; KL-FIN; EXTRUDED-FIN FINNED TUBES

Tension wound finned tubes, embedded finned tubes and extruded finned tubes are main devices for air coolers and the common application fields are:

- Heat exchangers for power plants (electric, nuclear, thermal and geothermal power plants)

- Steam condensate systems

- Chemical and petrochemical industry

- Food processing plants and refrigeration technology

- Industrial (steel mills, incinerators, gas compression facilities).