Low Fin Tube Manufacturing Process

Low fin tube manufacturing process

Copper Low Fin Tube

There are many processing methods for finned tubes. The fins can be “bonded” to the base tube through processes such as welding, fitting, and inlaying. The fins can also be processed on the plain tube through pressure processing methods such as rolling and rolling. In recent years, some scholars have combined the advantages of pressure processing and mechanical processing and creatively proposed a series of composite processing methods, such as “cutting-extrusion” processing method, “double-sided plowing method”, and “cutting-extrusion forming method”. Processing of integral finned tubes. The following takes the “cutting-extrusion” method as an example to introduce its processing technology:

Splitting-extrusion processing method This is a composite processing method that combines chipless cutting and extrusion. This method is to process the finned tube on an ordinary lathe according to the usual cutting processing method; the metal on the surface of the tube is split using a special tool. After opening, as the amount of extrusion increases, the metal flows in the radial and axial directions, and the metal is plastically deformed to form fins through radial and axial extrusion.

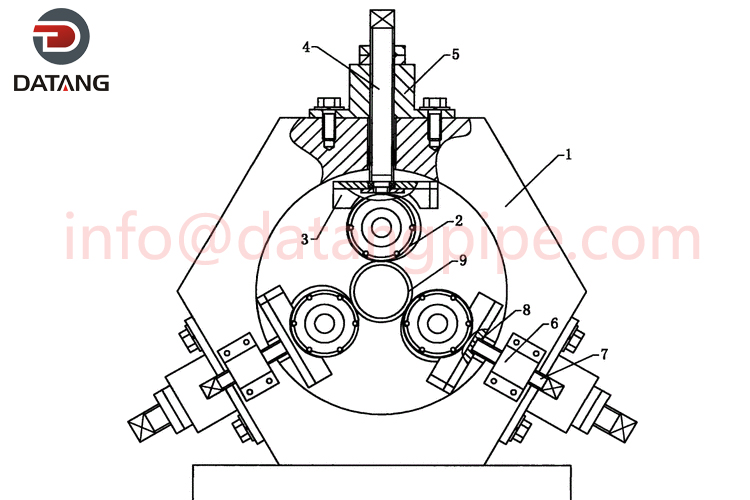

Low finned tubes are produced using the rolling method (three-roller cross-rolling). The working principle is as follows: a bare tube is lined with a mandrel, and the tube material makes a spiral linear motion driven by the roller blades. The groove formed by the slot and mandrel gradually creates fins on its outer surface.

Low finned tube manufacturing process

In order to facilitate fin forming, the rolled parts adopt three stages of biting, rolling and shaping during the deformation process to make the processed fins complete, smooth and regular. The fin tube produced by this method is different from the base tube. The outer fin is an organic whole, so there is no problem of contact thermal resistance loss and electrical corrosion. It has good heat transfer efficiency and strong resistance to deformation.