Characteristics and applications of stainless steel fin tubes

- Material characteristics of stainless steel finned tubes

Stainless steel finned tubes are mainly made of stainless steel and have good corrosion resistance and oxidation resistance. Stainless steel material performs well in harsh environments such as high temperature, high pressure, and corrosive media, so stainless steel finned tubes are suitable for a variety of complex working conditions.

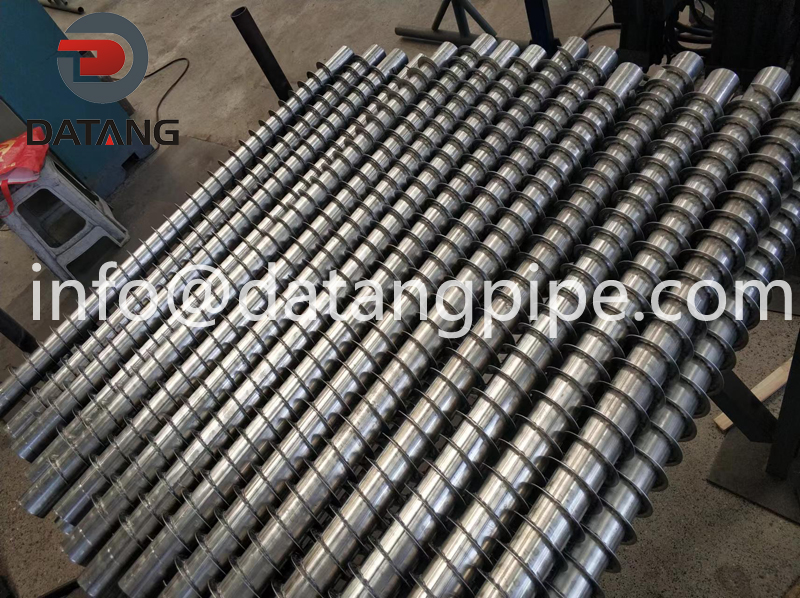

Stainless steel finned tubes for heat exchanger-Datang fin tube

- Manufacturing process of stainless steel finned tubes

The manufacturing process of stainless steel fin tubes mainly includes fin forming, welding and surface treatment. Fin forming usually uses mechanical processing or cold rolling forming technology to ensure the shape and size accuracy of the fins. The welding process uses advanced welding technologies such as argon arc welding or laser welding to ensure a firm connection between the fins and the base tube. Surface treatment mainly involves pickling, passivation and other treatments on the finned tubes to improve their corrosion resistance and aesthetics.

- Performance characteristics of stainless steel finned tubes

Corrosion resistance: Stainless steel finned tubes have good corrosion resistance and can resist the corrosive effects of atmosphere, water, steam and other media.

High temperature stability: Stainless steel has good stability and oxidation resistance at high temperatures, so stainless steel finned tubes are suitable for high temperature heat exchangers.

Long life: Due to the superiority of materials and manufacturing processes, stainless steel finned tubes have a long service life.

Heat transfer efficiency: The heat transfer efficiency of stainless steel finned tubes is high, which can effectively improve the overall performance of the heat exchanger.

- Application fields of stainless steel finned tubes

Stainless steel finned tubes are widely used in heat exchangers in petrochemical, electric power, metallurgy, medicine and other industries, and are especially suitable for harsh and corrosive working conditions.