Spiral fin tube technical advantages

Spiral fin tube is an efficient heat transfer element with spiral fins. Its heat transfer area is several to dozens of times that of a light tube, which can enhance heat transfer, reduce flow resistance, and reduce metal consumption, thereby improving the economy and operational reliability of heat exchange equipment. Spiral finned tubes have been widely used in various boilers. Spiral finned tubes can be manufactured using a variety of methods. The finned tubes used in heat exchange equipment such as boilers and pressure vessels mainly include the following manufacturing methods: high-frequency resistance welding spiral finned tubes, brazed spiral finned tubes and Integral spiral fin tube. The manufacturing method, performance evaluation index, application and advantages of the integral spiral fin tube are introduced in detail.

Spiral finned tubes have been widely used in heat recovery of boiler economizers, air preheaters and waste heat boilers, as well as heat exchange equipment in various fields such as chemical industry and pressure vessels. The capacity of the units used in boilers is also increasing from small to large, and their applications are increasing day by day. There are many domestic professional manufacturers that can produce high-frequency welding and brazing spiral finned tubes. The finned tube production equipment and technology have been introduced, digested, and absorbed to self-developed, designed, and manufactured. The quality has reached the requirements of advanced foreign standards. .

Advantages of using finned tubes:

1) The heat exchange area is increased in the effective space to improve the heat transfer effect.

2) Reduce the space occupied by the heat transfer surface and reduce its volume, especially suitable for quick-installation boilers.

3) Reduce equipment costs and improve equipment safety.

4) The operating cost is reduced due to the reduction of water side pressure drop.

5) The stiffness of the finned tube is increased, which improves the seismic resistance of the tube.

Spiral fin tube manufacturing method

Spiral finned tubes can be manufactured by a variety of methods. The finned tubes used in heat exchange equipment such as boilers and pressure vessels mainly include the following manufacturing methods:

High frequency resistance welding spiral fin tube

High-frequency resistance welding of spiral finned tubes introduces high-power high-frequency current into the parts to be welded, and uses the resistance heat generated by the current through the contact surface and adjacent areas of the joints of the parts to be welded to make the welding contact surface achieve molten or semi-melted plasticity. state, and then apply appropriate pressure to the welding contact surface to complete the welding of the fin tube.

Brazed spiral fin tube

Brazing spiral finned tube is to fill the space between the parts to be welded with a filler metal with a lower melting point than the welding parts, and then heat it to the brazing temperature. When the welding parts do not melt, the filler metal melts and wets the brazing well. However, the brazing joint is formed by diffusion at the contact point of the welded parts, thereby completing the welding of the spiral fin tube.

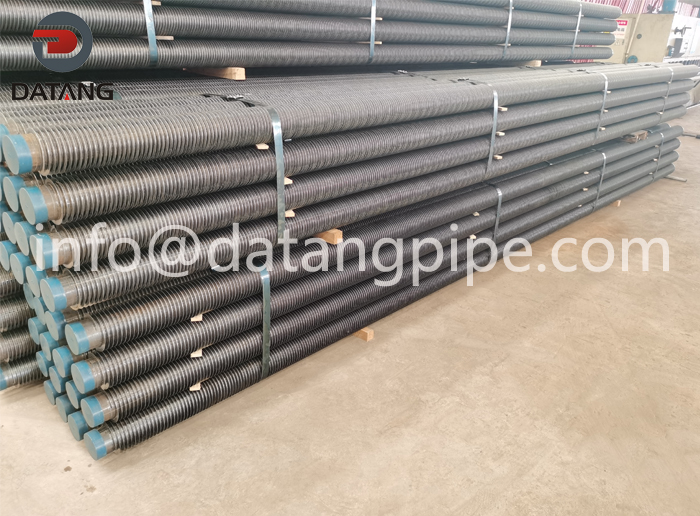

Integral spiral fin tube

Integral spiral finned tube is an integral spiral finned tube that is formed at one time by extruding and rolling thick-walled tubes (blank tubes) under medium-frequency continuous heating. It is the latest method of manufacturing finned tubes. .

Spiral fin tube technical advantages

The spiral fin steel pipes used are mostly wound, high-frequency welded, and brazed spiral fin steel pipes. The integral spiral finned steel pipe has become a replacement product of the above three forms of spiral finned steel pipes due to its long service life, stable heat transfer performance and obvious energy saving effect. Its advantages are as follows:

- Long service life, more than 3 times that of winding and welded finned steel pipes.

- The fin root and the tube form an arc cut, and the fin surface is smooth, which completely eliminates the dust accumulation, dust blocking, and slagging phenomena that are easily caused by other forms of fin tubes due to uneven folding of the fin roots.

- It is produced by hot rolling process, which improves the density, yield strength, tensile strength and wear resistance of the metal structure.

- Since the fins and the tube are an integrated structure and are distributed in a spiral band, the pressure-bearing capacity of the integral spiral finned steel pipe is more than three times that of the seamless steel pipe with the same wall thickness and inner diameter.

- Wear resistance, which solves the problem of serious wear of the convection heating surface of coal-fired boilers due to high wind speed and large ash concentration. (especially circulating fluidized bed boilers)

- The fins and tubes are an integrated structure, which completely eliminates the contact thermal resistance that cannot be overcome by other forms of finned steel tubes because the fins and tubes are two-body structures, and the longitudinal section of the fins is a trapezoidal structure, thus maximizing the Fin heat transfer efficiency.

- Integral spiral fins are used to extend surface heat exchange. Under the same working conditions, the heat transfer coefficient of the tube bundle is 3.5-5.5 times that of seamless steel pipes with the same wall thickness and inner diameter, and is higher than that of welded spiral fin pipes of the same specification. 2 times.

- The fins and the tube are an integrated structure, so they can be used in workplaces with high temperatures and harsh environments, and will not cause unstable heat transfer performance due to loosening or falling off of fins that is easily caused by other forms of finned steel tubes.